Welcome to our websites!

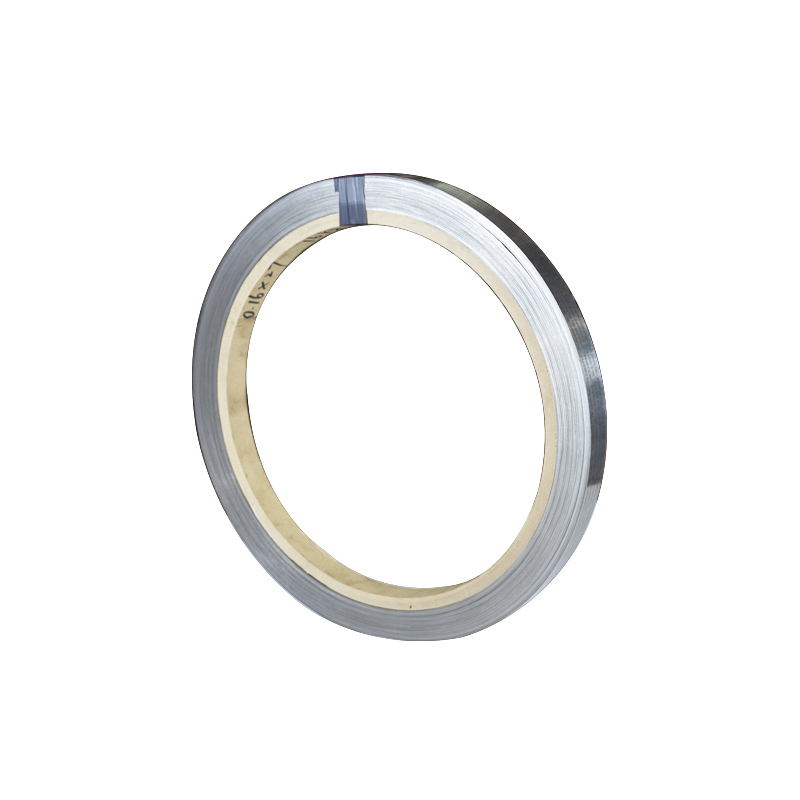

0.16mm x 27mm P675R/TM2/TB20110 Bimetallic Strip ASTM B388 Rapid Thermal Response & Durability

Product Description

P675R Bimetallic Strip (0.16mm Thickness × 27mm Width)

Product Overview

The P675R bimetallic strip (0.16mm×27mm), a precision-engineered functional material from Tankii Alloy Material, is a specialized composite strip composed of two dissimilar alloys with distinct thermal expansion coefficients—firmly bonded via our proprietary hot-rolling and diffusion bonding technology. With a fixed thin gauge of 0.16mm and standard width of 27mm, this strip is optimized for miniaturized temperature-sensitive applications, where precise thermal actuation, stable dimensionality, and space-saving design are critical. Leveraging Huona’s expertise in bimetallic composite processing, the P675R grade delivers consistent temperature-driven deformation performance, outperforming generic bimetallic strips in micro-device compatibility and long-term fatigue resistance—making it ideal for compact thermostats, overheat protectors, and precision temperature compensation components.

Standard Designations & Core Composition

- Product Grade: P675R

- Dimensional Specification: 0.16mm thickness (tolerance: ±0.005mm) × 27mm width (tolerance: ±0.1mm)

- Composite Structure: Typically features a “high-expansion layer”and a “low-expansion layer”, with interfacial shear strength ≥160 MPa

- Compliant Standards: Adheres to GB/T 14985-2017 (Chinese standard for bimetallic strips) and IEC 60694 for thermal control components

- Manufacturer: Tankii Alloy Material, certified to ISO 9001 and ISO 14001, with in-house thin-gauge composite rolling and precision slitting capabilities

Key Advantages (vs. Generic Thin-Gauge Bimetallic Strips)

The P675R strip (0.16mm×27mm) stands out for its thin-gauge-specific performance and fixed-width convenience:

- Ultra-Thin Stability: Maintains uniform thickness (0.16mm) and no interfacial delamination—even after 5000 thermal cycles (-40℃ to 180℃)—solving the common issue of thin-gauge bimetallic strips (≤0.2mm) being prone to warping or layer separation.

- Precise Thermal Actuation: Controlled 温曲率 (temperature-induced curvature) of 9-11 m⁻¹ (at 100℃ vs. 25℃), with actuation temperature deviation ≤±1.5℃—critical for compact devices (e.g., micro-battery overheat protectors) where temperature thresholds are narrow.

- Fixed Width for Automated Production: 27mm standard width matches common micro-stamping die sizes, eliminating the need for secondary slitting and reducing material waste by ≥15% compared to custom-width strips.

- Good Machinability: Thin 0.16mm gauge enables easy bending (minimum bending radius ≥2× thickness) and laser cutting into micro-shapes (e.g., tiny thermostat contacts) without cracking—compatible with high-speed automated assembly lines.

- Corrosion Resistance: Optional surface passivation treatment provides 72-hour salt spray resistance (ASTM B117) with no red rust, suitable for humid environments (e.g., wearable device temperature sensors).

Technical Specifications

| Attribute | Value (Typical) |

|---|---|

| Thickness | 0.16mm (tolerance: ±0.005mm) |

| Width | 27mm (tolerance: ±0.1mm) |

| Length per Roll | 100m – 300m (cut-to-length available: ≥50mm) |

| Thermal Expansion Coefficient Ratio (High/Low Layer) | ~13.6:1 |

| Operating Temperature Range | -70℃ to 350℃ |

| Rated Actuation Temperature Range | 60℃ – 150℃ (customizable via alloy ratio adjustment) |

| Interfacial Shear Strength | ≥160 MPa |

| Tensile Strength (Transverse) | ≥480 MPa |

| Elongation (25℃) | ≥12% |

| Resistivity (25℃) | 0.18 – 0.32 Ω·mm²/m |

| Surface Roughness (Ra) | ≤0.8μm (mill finish); ≤0.4μm (polished finish, optional) |

Product Specifications

| Item | Specification |

|---|---|

| Surface Finish | Mill finish (oxide-free) or passivated finish (for corrosion resistance) |

| Flatness | ≤0.08mm/m (critical for micro-stamping accuracy) |

| Bonding Quality | 100% interfacial bonding (no voids >0.05mm², verified via X-ray inspection) |

| Solderability | Optional tin-plating (thickness: 3-5μm) for enhanced solderability with Sn-Pb/lead-free solders |

| Packaging | Vacuum-sealed in anti-oxidation aluminum foil bags with desiccants; plastic spools (150mm diameter) to prevent strip deformation |

| Customization | Adjustment of actuation temperature (30℃ – 200℃), surface coating (e.g., nickel-plating), or pre-stamped shapes (per customer CAD files) |

Typical Applications

- Compact Temperature Controls: Micro-thermostats for wearable devices (e.g., smart watches), small household appliances (e.g., mini rice cookers), and medical devices (e.g., insulin coolers).

- Overheat Protection: Miniature circuit breakers for lithium-ion batteries (e.g., power banks, wireless earbud batteries) and micro-motors (e.g., drone motors).

- Precision Compensation: Temperature-compensating shims for MEMS sensors (e.g., pressure sensors in smartphones) to offset thermal expansion-induced measurement errors.

- Consumer Electronics: Thermal actuators for laptop keyboard backlight controls and printer fuser temperature regulators.

- Industrial Micro-Devices: Tiny thermal switches for IoT sensors (e.g., smart home temperature/humidity sensors) and automotive micro-components (e.g., fuel system temperature monitors).

Tankii Alloy Material subjects every batch of P675R bimetallic strips (0.16mm×27mm) to rigorous quality testing: interfacial bonding shear tests, 1000-cycle thermal stability tests, dimensional inspection via laser micrometry, and actuation temperature calibration. Free samples (50mm×27mm) and detailed performance reports (including 温曲率 vs. temperature curves) are available upon request. Our technical team provides tailored support—such as alloy layer optimization for specific actuation temperatures and micro-stamping process guidelines—to ensure the strip meets the exact needs of compact, precision-driven applications.

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top