Welcome to our websites!

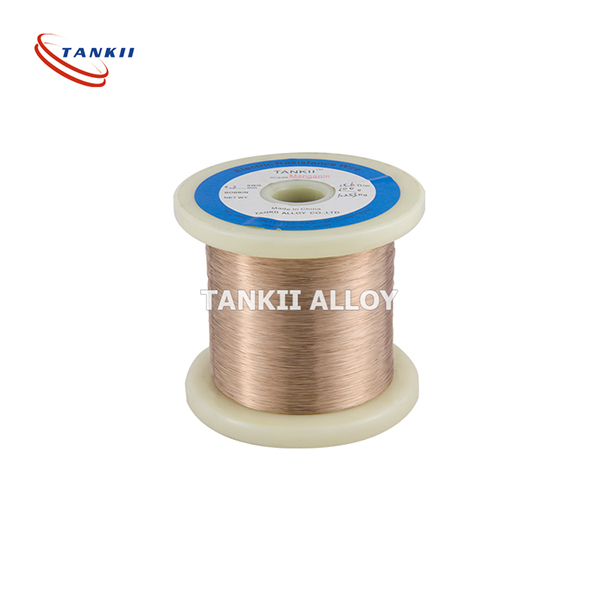

24AWG 36AWG Resistance Wire Manganin 6j12 for Precision Instrument

|

Product Name |

24AWG 36AWG Resistance Wire Manganin 6j12 for Precision Instrument |

| Brand Name | TANKII |

| Material | Manganese copper alloy |

| Surface | Bright |

| Standard | GB/ASTM |

| MOQ | Sample Accepted |

Manganese copper alloy wire is a type of wire that is composed of a combination of manganese and copper.

This alloy is known for its high strength, excellent electrical conductivity, and good corrosion resistance. It is commonly used in various applications such as electrical wiring, power transmission, and telecommunications. The addition of manganese to copper helps improve the mechanical properties and overall performance of the wire.

Cu Mn alloy is a widely used damping material, belonging to the category of thermoelastic martensitic transformation. When this type of alloy undergoes aging heat treatment at 300-600 ℃, the alloy structure transforms into a normal martensitic twin structure, which is extremely unstable. When subjected to alternating vibration stress, it will undergo rearrangement movement, absorbing a large amount of energy and exhibiting damping effect.

Properties of manganin wire:

1. A lower resistance temperature coefficient, 2. Wide temperature range for use, 3. Good processing performance, 4. Good welding performance.

Manganese copper is a precision resistance alloy, usually supplied in wire form, with small quantities of plates and strips, At present, there are three grades in China: BMn3-12 (also known as manganese copper), BMn40-1.5 (also known as constantan), and BMn43-0.5.

Application: Suitable for precision resistors, sliding resistors, starting and regulating transformers, and resistance strain gauges for communication purposes

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top