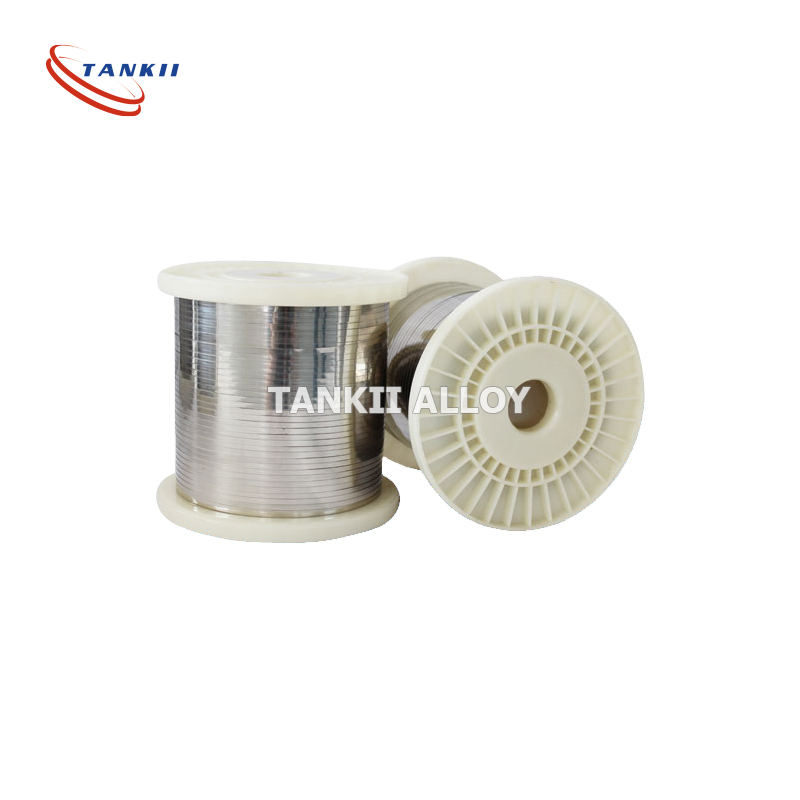

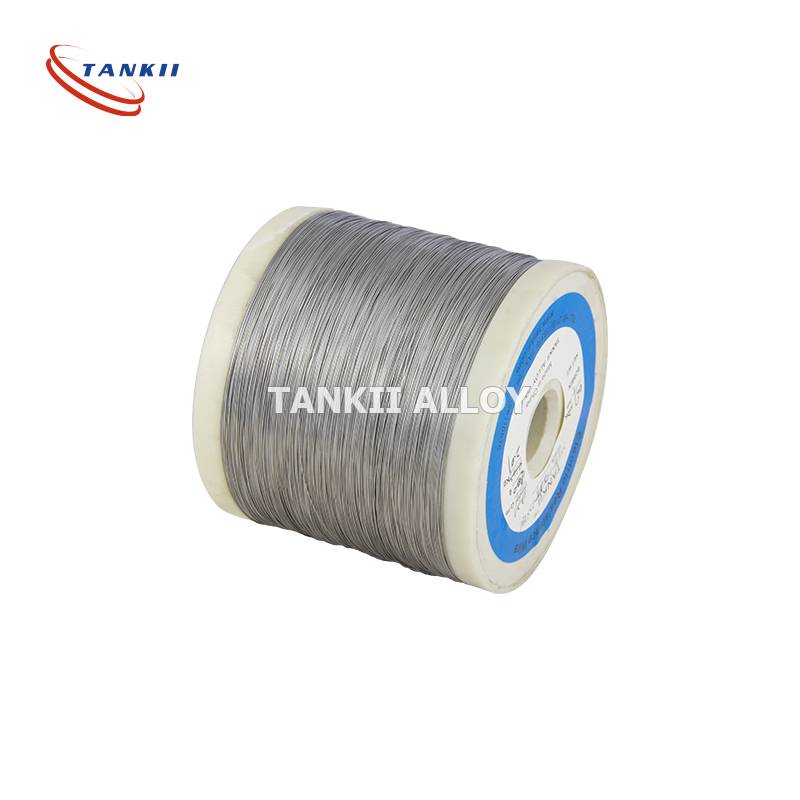

Alkrothal 14 / 1cr13al4 Fecral Alloy Heating Resistance Strip

Hot Fecral Alloy Deals Fecral13/4 Wire for Blower Motor Resistor

Common name: 1Cr13Al4, Alkrothal 14, Alloy 750, Alferon 902, Alchrome 750, Resistohm 125, Aluchrom W, 750 Alloy, Stablohm 750.

TANKII 125 is a iron-chromium-aluminium alloy (FeCrAl alloy) characterized by Stable performance, Anti-oxidation,Corrosion resistance,High temperature stability,Excellent coil-forming ability,Uniform and beautiful surface condition without spots.It is suitable for use at temperatures up to 950°C.

Typical applications for TANKII125 are used in electric locomotive, diesel locomotive,metro vehicle and high speed moving car etc brake system brake resistor,electric ceramic cooktop,industrial furnace.

Normal composition%

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Other |

| Max | |||||||||

| 0.12 | 0.025 | 0.025 | 0.70 | Max 1.0 | 12.0~15.0 | Max 0.60 | 4.0~6.0 | Bal. | - |

Typical Mechanical properties(1.0mm)

| Yield strength | Tensile Strength | Elongation |

| Mpa | Mpa | % |

| 455 | 630 | 22 |

Typical Physical properties

| Density (g/cm3) | 7.40 |

| Electrical resistivity at 20ºC(ohm mm2/m) | 1.25 |

| Conductivity coefficient at 20ºC (WmK) | 15 |

Coefficient of thermal expansion

| Temperature | Coefficient of Thermal Expansion x10-6/ºC |

| 20 ºC- 1000ºC | 15.4 |

Specific heat capacity

| Temperature | 20ºC |

| J/gK | 0.49 |

| Melting point (ºC) | 1450 |

| Max continuous operating temperature in air (ºC) | 950 |

| Magnetic properties | non-magnetic |

Nominal Analysis

Max contineous working temperature: 1250ºC.

Melting Temperature: 1450ºC

Electric Resistivity: 1.25 ohm mm2/m

Has been used extensively as heating elements in industrial furnaces and electrical kilns.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top