Best quality Alloy 120 - Alloy 180 Manganin Insulated Enameled Copper Nickel CuNi Resistance Wire – TANKII

Best quality Alloy 120 - Alloy 180 Manganin Insulated Enameled Copper Nickel CuNi Resistance Wire – TANKII Detail:

Round Copper Based Nicr Alloy 180 degree Class Insulated Enameled Copper Wire

1.Material General Description

1)

Manganin is an alloy of typically 84% copper, 12% manganese, and 4% nickel.

Manganin wire and foil are used in the manufacture of resistors, particularl ammeter shunt, because of its virtually zero temperature coefficient of resistance and long term stability. Several Manganin resistors served as the legal standard for the ohm in the United States from 1901 to 1990. Manganin wire is also used as an electrical conductor in cryogenic systems, minimizing heat transfer between points which need electrical connections.

Manganin is also used in gauges for studies of high-pressure shock waves (such as those generated from the detonation of explosives) because it has low strain sensitivity but high hydrostatic pressure sensitivity.

2)

Constantan is a copper-nickel alloy also known as Eureka, Advance, and Ferry. It usually consists of 55% copper and 45% nickel. Its main feature is its resistivity, which is constant over a wide range of temperatures. Other alloys with similarly low temperature coefficients are known, such as manganin (Cu86Mn12Ni2).

For the measurement of very large strains, 5% (50 000 microstrian) or above, annealed constantan (P alloy) is the grid material normally selected. Constantan in this form is very ductile; and, in gauge lengths of 0.125 inches (3.2 mm) and longer, can be strained to >20%. It should be borne in mind, however, that under high cyclic strains the P alloy will exhibit some permanent resistivity change with each cycle, and cause a corresponding zero shift in the strain gauge. Because of this characteristic, and the tendency for premature grid failure with repeated straining, P alloy is not ordinarily recommended for cyclic strain applications. P alloy is available with S-T-C numbers of 08 and 40 for use on metals and plastics, respectively.

2. Enamelled Wire Introduction and applications

Although described as “enameled”, enameled wire is not, in fact, coated with either a layer of enamel paint nor with vitreous enamel made of fused glass powder. Modern magnet wire typically uses one to four layers (in the case of quad-film type wire) of polymer film insulation, often of two different compositions, to provide a tough, continuous insulating layer. Magnet wire insulating films use (in order of increasing temperature range) polyvinyl formal (Formar), polyurethane, polyimide, polyamide, polyster, polyester-polyimide, polyamide-polyimide (or amide-imide), and polyimide. Polyimide insulated magnet wire is capable of operation at up to 250 °C. The insulation of thicker square or rectangular magnet wire is often augmented by wrapping it with a high-temperature polyimide or fiberglass tape, and completed windings are often vacuum impregnated with an insulating varnish to improve insulation strength and long-term reliability of the winding.

Self-supporting coils are wound with wire coated with at least two layers, the outermost being a thermoplastic that bonds the turns together when heated.

Other types of insulation such as fiberglass yarn with varnish, aramid paper, kraft paper, mica, and polyester film are also widely used across the world for various applications like transformers and reactors. In the audio sector, a wire of silver construction, and various other insulators, such as cotton (sometimes permeated with some kind of coagulating agent/thickener, such as beeswax) and polytetrafluoroethylene (PTFE) can be found. Older insulation materials included cotton, paper, or silk, but these are only useful for low-temperature applications (up to 105°C).

For ease of manufacturing, some low-temperature-grade magnet wire has insulation that can be removed by the heat of soldering. This means that electrical connections at the ends can be made without stripping off the insulation first.

3.Chemical Composition and Main Property of Cu-Ni Low Resistance Alloy

| PropertiesGrade | CuNi1 | CuNi2 | CuNi6 | CuNi8 | CuMn3 | CuNi10 | |

| Main Chemical Composition | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | Bal | Bal | Bal | Bal | Bal | Bal | |

| Max Continuous Service Temperature(oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Resisivity at 20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Density(g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Thermal Conductivity(α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Tensile Strength(Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Approximate Melting Point( oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Micrographic Structure | austenite | austenite | austenite | austenite | austenite | austenite | |

| Magnetic Property | non | non | non | non | non | non | |

| PropertiesGrade | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNi44 | |

| Main Chemical Composition | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | Bal | Bal | Bal | Bal | Bal | Bal | |

| Max Continuous Service Temperature(oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Resisivity at 20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Density(g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Thermal Conductivity(α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Tensile Strength(Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Approximate Melting Point( oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Micrographic Structure | austenite | austenite | austenite | austenite | austenite | austenite | |

| Magnetic Property | non | non | non | non | non | non | |

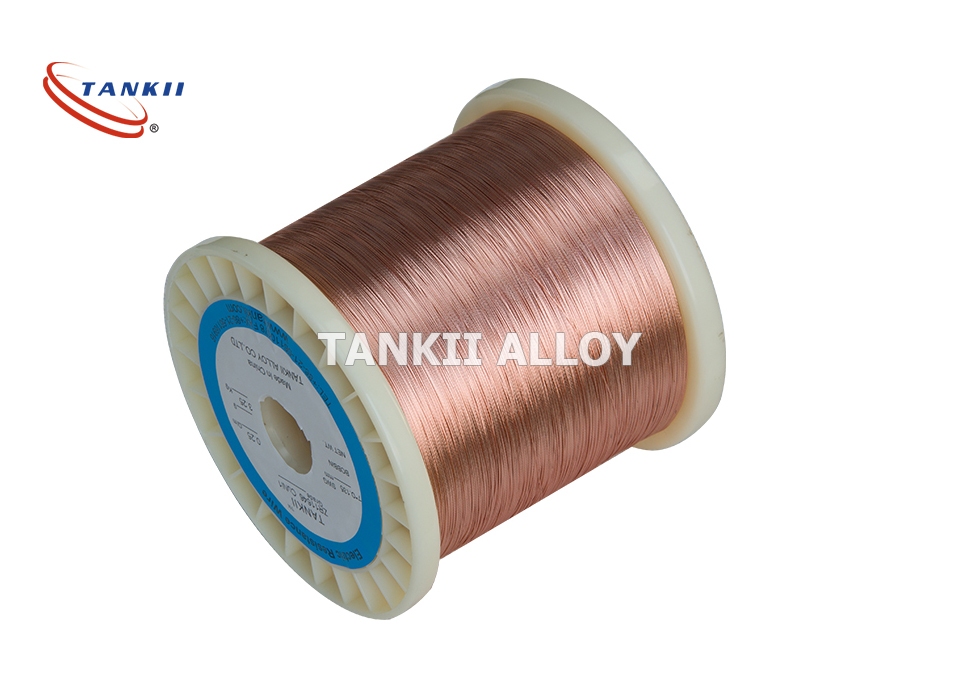

Product detail pictures:

Related Product Guide:

We follow our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create much more worth for our buyers with our abundant resources, highly developed machinery, experienced workers and great providers for Best quality Alloy 120 - Alloy 180 Manganin Insulated Enameled Copper Nickel CuNi Resistance Wire – TANKII , The product will supply to all over the world, such as: Qatar, Sheffield, Cyprus, We adhere to the honest, efficient, practical win-win running mission and people-oriented business philosophy. Excellent quality, reasonable price and customer satisfaction are always pursued! If you are interested in our products, just try to contact us for more details!

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.