Welcome to our websites!

Chromel A/Nickel Alloy Nicr 80/20 Flat Wire for Aviation, Electronics

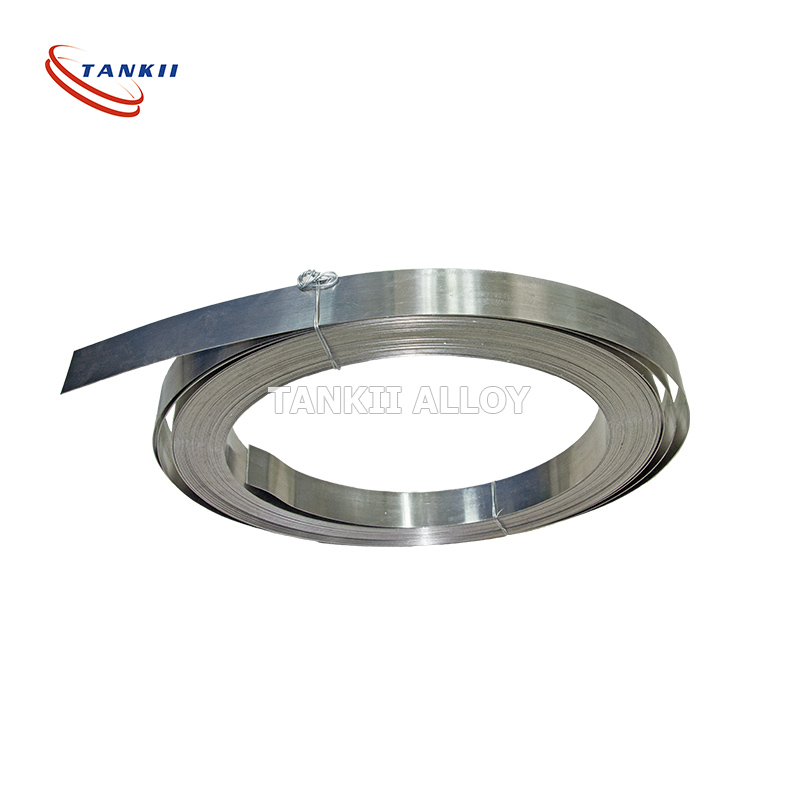

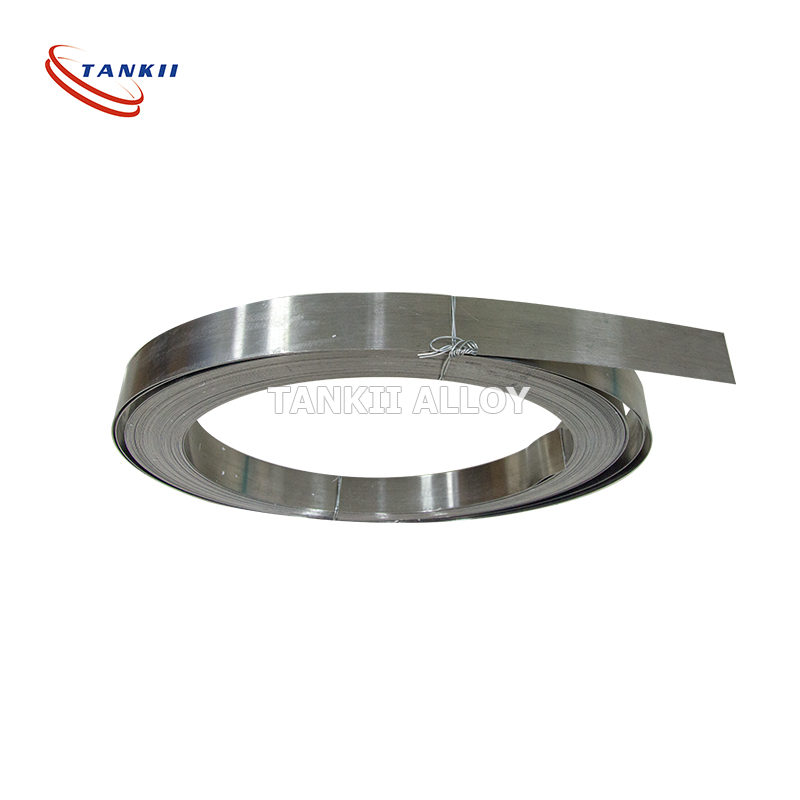

Nickel Alloy NiCr 80/20 Nichrome Strip Ni-Cr Flat Wire

Description

| Model NO. | NiCr8020 | Density | 8.4 g/cm3 |

| Material Shape | Strip | Melting Point | 1400 C |

| Range of Application | Resistor, Heater | OEM | YES |

| Certification | ISO9001, RoHS | Stock | Seyn |

| Brand | HUONA | Tensile Strength | 810 MPa |

| Usage | Resistance materials | Electrical Resistivity | 1.09 |

| Elongation | >20% | Trademark | HUONA |

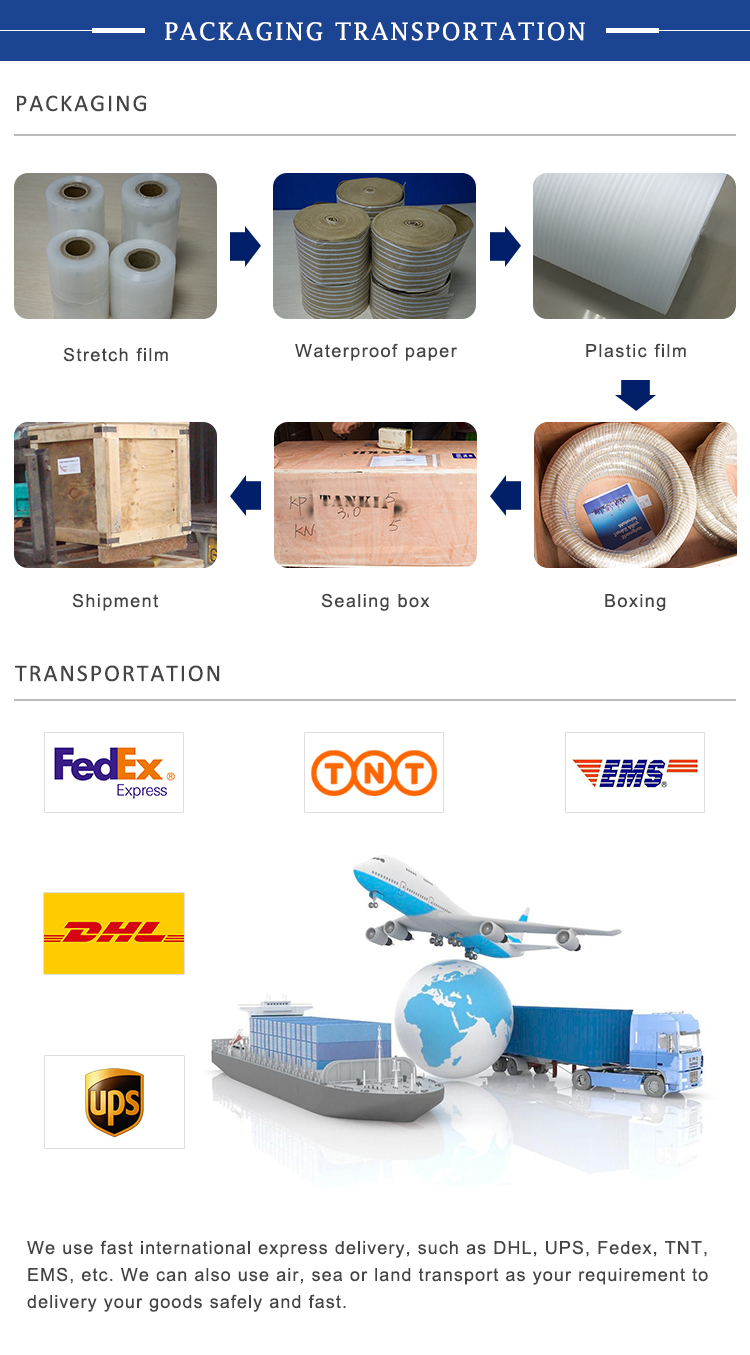

| Hardness | 180 HV | Transport Package | Spool, Carton, Wooden Case |

| Max Working Temperature | 1200 C | Specification | 0.8mm |

| HS Code | 7506200000 | Origin | China |

| Chemical Composition and Propertes: | ||||||

| Propertes/Grade | NiCr 80/20 | NiCr 70/30 | NiCr 60/15 | NiCr 35/20 | NiCr 30/20 | |

| Main Chemical Composition(%) | Ni | Bal. | Bal. | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe | ≤ 1.0 | ≤ 1.0 | Bal. | Bal. | Bal. | |

| Max Working Temperature(ºC) | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Resistivity at 20ºC(μ Ω · m) | 1.09 | 1.18 | 1.12 | 1.04 | 1.04 | |

| Density(g/cm3) | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Thermal Conductivity(KJ/m· h· ºC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Coefficient of Thermal Expansion(α × 10-6/ºC) | 18 | 17 | 17 | 19 | 19 | |

| Melting Point(ºC) | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Elongation(%) | > 20 | > 20 | > 20 | > 20 | > 20 | |

| Micrographic Structure | austenite | austenite | austenite | austenite | austenite | |

| Magnetic Property | nonmagnetic | nonmagnetic | nonmagnetic | nonmagnetic | nonmagnetic | |

| Chemical Composition | Nickel 80%, Chrome 20% |

| Condition | Bright/Acid white/Oxidied Color |

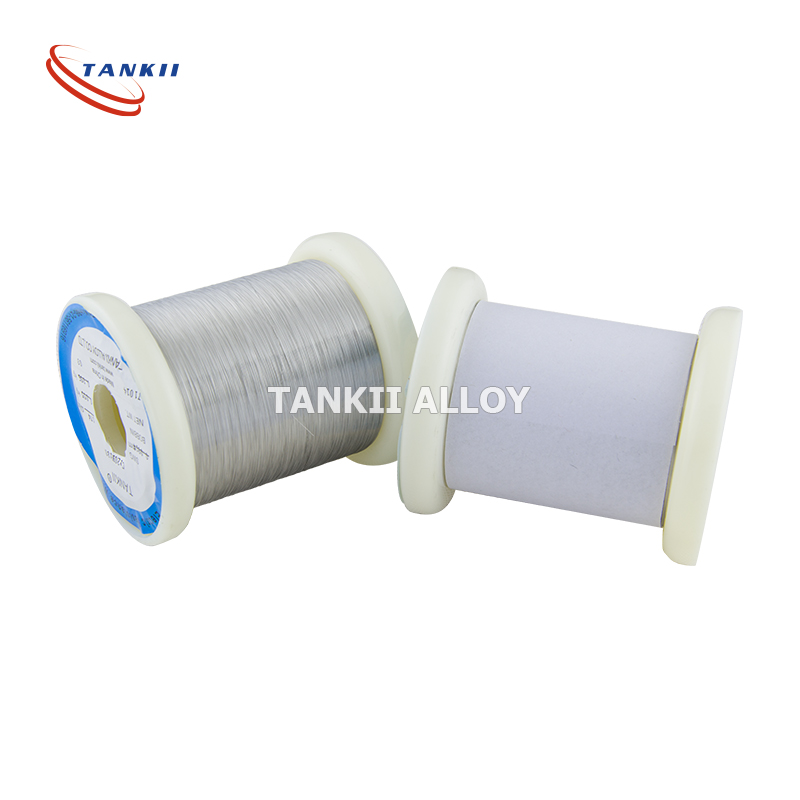

| Diameter | 0.018mm~1.6mm in spool, 1.5mm-8mm packing in coil, 8~60mm in rod |

| Nichrome Strip | Width 450mm~1mm, thickness 0.001m~7mm |

| Diameter | 1.5mm-8mm packing in coil, 8~60mm in rod |

| Grade | Ni80Cr20, Ni70/30, Ni60Cr15, Ni60Cr23, Ni35Cr20Fe, Ni30Cr20 Ni80, Ni70,Ni60, Ni40, |

| Advantage | Nichrome’s metallurgical structure confers them a very good plasticity when cold. |

| Characteristics | Stable performance; Anti-oxidation; Corrosion resistance; High temperature stability; Excellent coil-forming ability; Uniform and beautiful surface condition without spots. |

| Usage | Resistance heating elements;Material in metallurgy;Household appliances; Mechanical manufacturing and other industries. |

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top