CuSn4 CuSn6 CuSn8 Phosphor Tin Bronze Coil Strip C5191

CuSn4 CuSn6 CuSn8 Phosphor Tin Bronze Coil Strip C5191 Detail:

CuSn4 CuSn6 CuSn8 Phosphor Tin Bronze Coil Strip

CuSn6 - UNS.C51900 Phosphor Bronze Alloys, which is a 6% tin bronze distinguished by a very good combinatio of strength and electrical conductivity. It is used for connector and current-carrying springs in contacts. Among the 4-8% tin bronze C51900 exhibits a high electrical conductivity, the highest reachable strength is significantly higher than C51100 and C51000. By means of an additional further tenpering after the cold forming process the bendability can be further improved.

Phosphor Bronze C51900 Chemical composition

| Articles | Chemical composition | |||||

| GB | UNS | EN | JIS | Cu% | Sn% | P% |

| QSn6.5-0.1 | C51900 | CuSn6 | C5191 | Rem | 5.5-7.0 | 0.03-0.35 |

| Chemical Composition | |||

| % | |||

| Sn | P | Cu | impurity |

| 7.0~9.0 | 0.15~0.35 | Bal. | ≤0.1 |

Phosphor Bronze Mechanical properties

| Mechanical Properties | |||||

| Temper | T.S(N/mm²) | Elongation(%) | Hardness(Hv) | ||

| M | O | O60 | ≥345 | ≥40 | / |

| Y4 | 1/4H | H01 | 390-510 | ≥35 | 100-160 |

| Y2 | 1/2H | H02 | 490-610 | ≥8 | 150-200 |

| Y | H | H04 | 590-705 | ≥5 | 190-230 |

| T | EH | H06 | 585-740 | / | 200-240 |

| TY | SH | H08 | ≥735 | / | ≥230 |

| Mechanical properties | |||||||

| State | Hardness(HV) | Tension test | Bending test | ||||

| thickness mm | tensile strength MPa | elongation % | thickness | angles | ID | ||

| 0 | - | 0.1-5.0 | ≥315 | ≥42 | ≤1.6 | 180° | 50% of thickness |

| 1/4H | 100-160 | 0.1-5.0 | 390-510 | ≥35 | ≤1.6 | 180° | 100% of thickness |

| 1/2H | 150-205 | 0.1-5.0 | 490-610 | ≥20 | ≤1.6 | 180° | 150% of thickness |

| H | 180-230 | 0.1-5.0 | 590-685 | ≥8 | ≤1.6 | 180° | 200% of thickness |

| EH | 200-240 | 0.1-0.2 | 635-720 | - | - | - | - |

| >0.2-5 | ≥5 | - | - | - | |||

| SH | ≥210 | 0.1-5.0 | ≥690 | - | - | - | - |

Phosphor Bronze C51900 Features for Phosphor Bronze Strips

- Elongation rate ≥25%

- Modulus of elasticity:125GPa

- Yield strength:≥90% tensile strength

- Fatigue performance

- Plating performance

- Excellent welding performance

- Excellent cold workability, deep drawing properties, flexural properties

Phosphor Bronze C51900 Typical application

Phosphor Bronze is widely used in counputer CPU slot, car terminal, cell phone buttons, electrical connectors and other high technical electronic field.

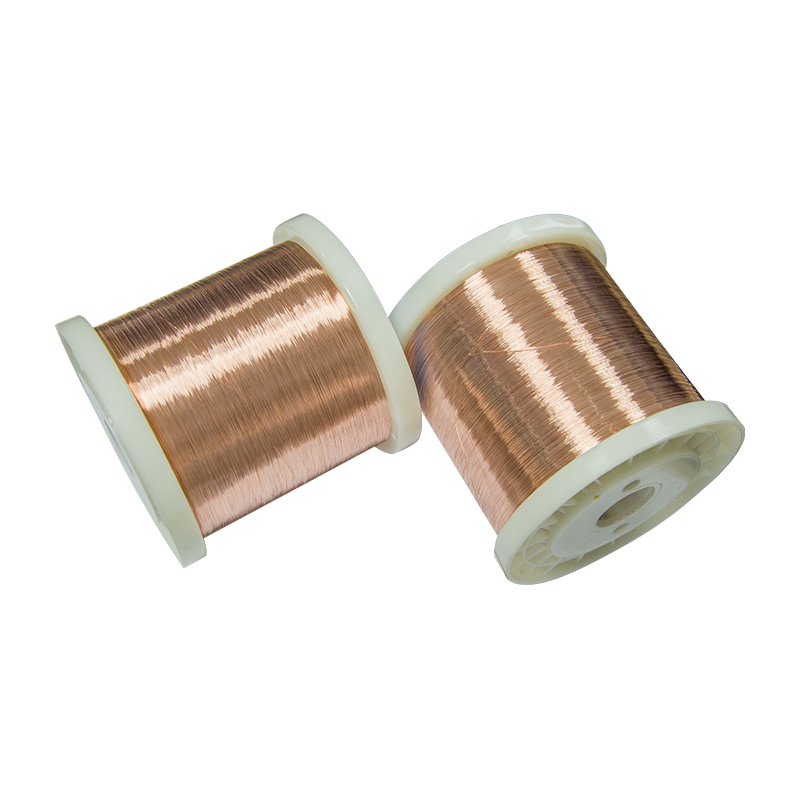

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for CuSn4 CuSn6 CuSn8 Phosphor Tin Bronze Coil Strip C5191 , The product will supply to all over the world, such as: Colombia, Rwanda, Angola, We can meet the various needs of customers at home and abroad. We welcome new and old customers to come to consult & negotiate with us. Your satisfaction is our motivation! Let us work together to write a brilliant new chapter!

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top