Edge Wound Resistors - Factory, Suppliers, Manufacturers from China

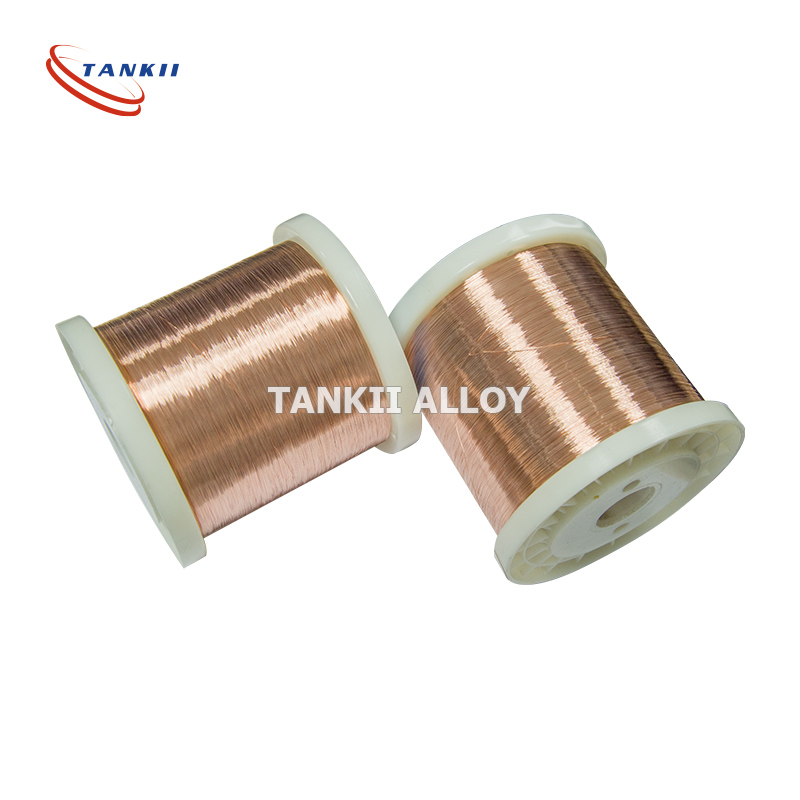

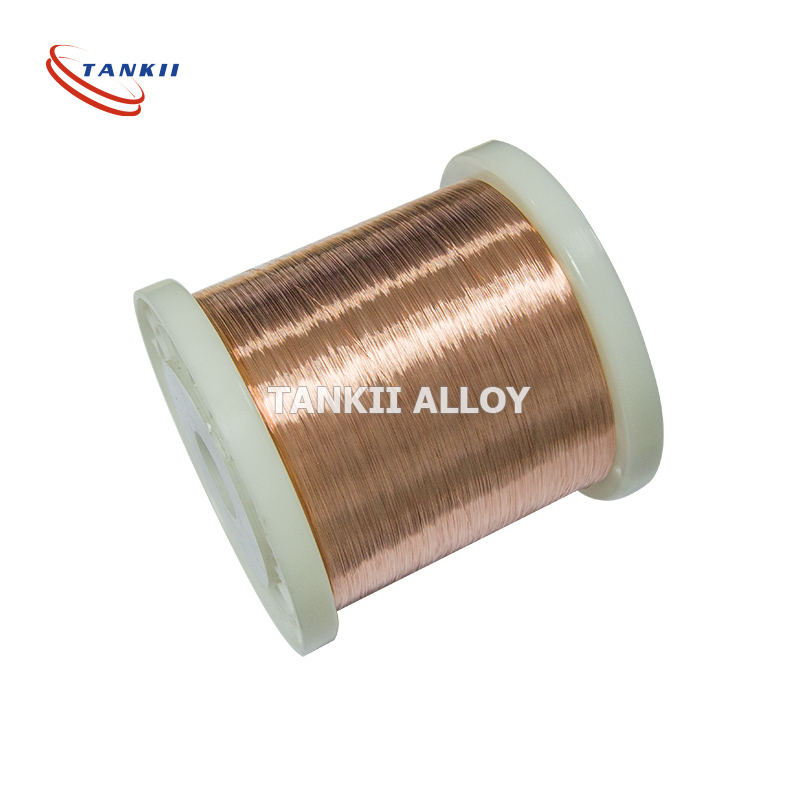

The very rich projects management experiences and one to one service model make the high importance of business communication and our easy understanding of your expectations for Edge Wound Resistors, Hai-Nicr 60 , X20h80 Wire , Nickel 200 Wire ,Cuprothal 60 . For more information, please contact us as soon as possible! The product will supply to all over the world, such as Europe, America, Australia,El Salvador, Melbourne,Hungary, United Arab Emirates.Due to our good products and services, we have received good reputation and credibility from local and international customers. If you need more information and are interested in any of our products, please feel free to contact us. We look forward to becoming your supplier in the near future.

Related Products