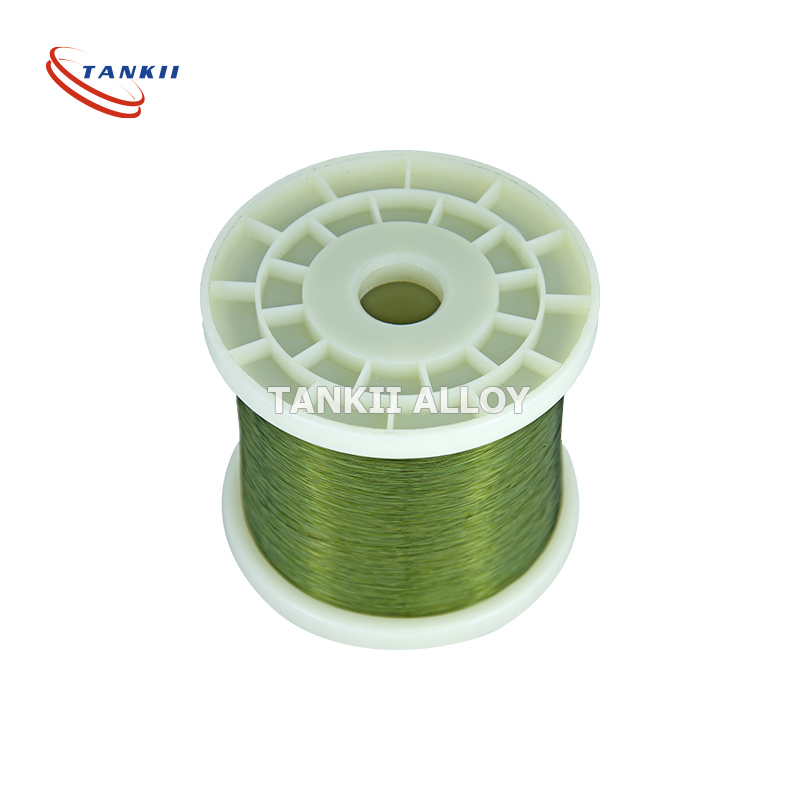

Enameled wire Ni80Cr20 NiCr8020 wire with good insulation performance

Product Description

Karma Enamelled Wire Dia 0.08mm Resistance Heating Wire for Precision Instrument

Product Description

These enameled resistance wires have been broadly used for standard resistors, automobile

parts, winding resistors, etc. using the insulation processing best suited for these applications, taking full advantage of the distinctive features of enamel coating.

Furthermore, we will carry out enamel coating insulation of precious metal wire such as silver and platinum wire upon order. Please make use of this production-on-order.

Karma Property

| name | code | Main Composition (%) |

Standard

|

|||

| Cr | Al | Fe | Ni | |||

| Karma | 6J22 | 19~21 | 2.5~3.2 | 2.0~3.0 | bal. | JB/T 5328 |

| Name | Code | (20ºC) Resisti vity |

(20ºC) Temp. Coeff. Of Resistance |

(0~100ºC) Thermal EMF vs. Copper |

Max.workin

g |

(%) Elongati on |

(N/mm2) Tensile Strength |

Standard |

| Karma | 6J22 | 1.33±0.07 | ≤±20 | ≤2.5 | ≤300 | >7 | ≥780 | JB/T 5328 |

4. Distinctive features of Karma resistance wire

1) Starting with Nickel Chromium electric heat wire Class 1, we replaced some of the Ni with

Al and other elements, and thus achieved a precision resistance material with improved

resistance temperature coefficient and heat electromotive force against copper.

With the addition of Al, we have succeeded in making volume resistivity 1.2 times greater

than Nickel Chromium electric heat wire Class 1 and the tensile strength 1.3 times greater.

2) The secondary temperature coefficient β of Karmalloy wire KMW is very small, - 0.03 × 10-6/ K2,

and the resistance temperature curve turns out to be almost a straight line within a wide

temperature range.

Therefore, the temperature coefficient is set to be the average temperature coefficient between

23 ~ 53 °C, but 1 × 10-6/K, the average temperature coefficient between 0 ~ 100 °C, also may

be adopted for the temperature coefficient.

3) Electromotive force against copper between 1 ~ 100 °C is also small, below + 2 μV/K, and

exhibits excellent stability over a period of many years.

4) If this is to be used as a precision resistance material, low temperature heat treatment is

required to eliminate processing distortions just as in the case of Manganin wire CMW.

Type of Insulation

| Insulation-enamelled Name | Thermal LevelºC

(working time 2000h) |

Code Name | GB Code | ANSI. TYPE |

| Polyurethane enamelled wire | 130 | UEW | QA | MW75C |

| Polyester enamelled wire | 155 | PEW | QZ | MW5C |

| Polyester-imide enamelled wire | 180 | EIW | QZY | MW30C |

| Polyester-imide and polyamide-imide double coated enameled wire | 200 | EIWH

(DFWF) |

QZY/XY | MW35C |

| Polyamide-imide enamelled wire | 220 | AIW | QXY | MW81C |

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top