Excellent quality Ceramic Hobs - Iron Chrome Aluminum Resistance Alloys – TANKII

Excellent quality Ceramic Hobs - Iron Chrome Aluminum Resistance Alloys – TANKII Detail:

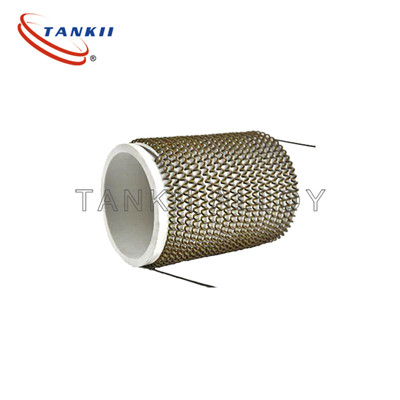

Iron Chrome Aluminum (FeCrAl) alloys are high-resistance materials typically used in applications with maximum operating temperatures up to 1,400°C (2,550°F).

These Ferritic alloys are known to have higher surface loading capability, higher resistivity and lower density than Nickel Chrome (NiCr) alternatives which can translate to less material in application and weight savings. The higher maximum operating temperatures can also lead to longer element life. Iron Chrome Aluminum alloys form a light grey Aluminum Oxide (Al2O3) at temperatures above 1,000°C (1,832°F) which increases corrosion resistance as well as acts as an electrical insulator. The oxide formation is considered self-insulating and protects against short circuiting in the event of metal to metal contact. Iron Chrome Aluminum alloys have lower mechanical strength when compared to Nickel Chrome materials as well as lower creep strength.

Specification of Cold-drawing Round Type heating wire

|

Diameter(mm) |

Tolerance(mm) |

Diameter(mm) |

Tolerance(mm) |

|

0.03-0.05 |

±0.005 |

>0.50-1.00 |

±0.02 |

|

>0.05-0.10 |

±0.006 |

>1.00-3.00 |

±0.03 |

|

>0.10-0.20 |

±0.008 |

>3.00-6.00 |

±0.04 |

|

>0.20-0.30 |

±0.010 |

>6.00-8.00 |

±0.05 |

|

>0.30-0.50 |

±0.015 |

>8.00-12.0 |

±0.4 |

Specification of Cold-drawing Strip Type heating wire

|

Thickness(mm) |

Tolerance(mm) |

Width(mm) |

Tolerance(mm) |

|

0.05-0.10 |

±0.010 |

5.00-10.0 |

±0.2 |

|

>0.10-0.20 |

±0.015 |

>10.0-20.0 |

±0.2 |

|

>0.20-0.50 |

±0.020 |

>20.0-30.0 |

±0.2 |

|

>0.50-1.00 |

±0.030 |

>30.0-50.0 |

±0.3 |

|

>1.00-1.80 |

±0.040 |

>50.0-90.0 |

±0.3 |

|

>1.80-2.50 |

±0.050 |

>90.0-120.0 |

±0.5 |

|

>2.50-3.50 |

±0.060 |

>120.0-250.0 |

±0.6 |

|

Alloy Type |

Diameter |

Resistivity |

Tensile |

Elongation(%) |

Bending |

Max.Continuous |

Working Life |

|

1Cr13Al4 |

0.03-12.0 |

1.25±0.08 |

588-735 |

>16 |

>6 |

950 |

>10000 |

|

0Cr15Al5 |

1.25±0.08 |

588-735 |

>16 |

>6 |

1000 |

>10000 |

|

|

0Cr25Al5 |

1.42±0.07 |

634-784 |

>12 |

>5 |

1300 |

>8000 |

|

|

0Cr23Al5 |

1.35±0.06 |

634-784 |

>12 |

>5 |

1250 |

>8000 |

|

|

0Cr21Al6 |

1.42±0.07 |

634-784 |

>12 |

>5 |

1300 |

>8000 |

|

|

1Cr20Al3 |

1.23±0.06 |

634-784 |

>12 |

>5 |

1100 |

>8000 |

|

|

0Cr21Al6Nb |

1.45±0.07 |

634-784 |

>12 |

>5 |

1350 |

>8000 |

|

|

0Cr27Al7Mo2 |

0.03-12.0 |

1.53±0.07 |

686-784 |

>12 |

>5 |

1400 |

>8000 |

Product detail pictures:

Related Product Guide:

Innovation, good quality and reliability are the core values of our enterprise. These principles today extra than ever form the basis of our success as an internationally active mid-size organization for Excellent quality Ceramic Hobs - Iron Chrome Aluminum Resistance Alloys – TANKII , The product will supply to all over the world, such as: Gambia, Madagascar, UAE, With the spirit of "high quality is our company's life; good reputation is our root", we sincerely hope to cooperate with customers from at home and abroad and hope to build a good relationship with you.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!