Welcome to our websites!

High Performance J Type Thermocouple Compensating Cable with FEP Insulation Precision Temperature Transmission

Product Description

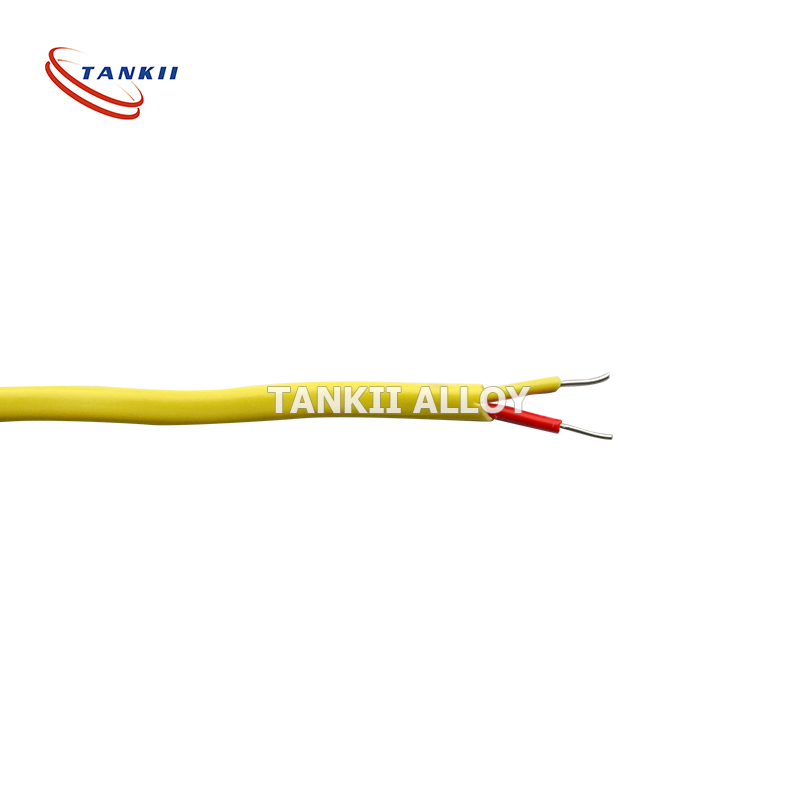

J – type Thermocouple Extension Wire with FEP Insulation

Product Overview

The J – type thermocouple extension wire with FEP (Fluorinated Ethylene Propylene) insulation is a specialized cable designed for accurately transmitting the thermoelectric potential generated by a J – type thermocouple to a measuring instrument. The FEP insulation offers excellent electrical insulation properties, high – temperature resistance, and chemical resistance. This type of extension wire is suitable for a wide range of industrial applications, including temperature measurement in chemical plants, power generation facilities, and food processing industries where exposure to harsh chemicals, high temperatures, or corrosive environments may occur.

Key Features

- Accurate Signal Transmission: Ensures precise transfer of the thermoelectric signal from the J – type thermocouple to the measuring device, minimizing errors in temperature measurement.

- High – Temperature Resistance: The FEP insulation can withstand continuous operating temperatures up to [specific temperature, e.g., 200°C] and short – term peaks even higher, making it suitable for high – temperature applications.

- Chemical Resistance: Resistant to a wide variety of chemicals, including acids, alkalis, and solvents, protecting the wire from degradation in corrosive environments.

- Excellent Electrical Insulation: Provides reliable electrical insulation, reducing the risk of electrical interference and ensuring stable signal transmission.

- Flexibility: The wire is flexible, allowing for easy installation in tight spaces and complex routing requirements.

- Long – term Durability: Designed for long – term use, with good resistance to aging, UV radiation, and mechanical abrasion.

Technical Specifications

| Attribute | Value |

|---|---|

| Conductor Material |

Positive: Iron Negative: Constantan (Nickel – Copper alloy) |

| Conductor Gauge | Available in standard gauges such as AWG 18, AWG 20, AWG 22 (customizable) |

| Insulation Thickness | Varies depending on the conductor gauge, typically [specify thickness range, e.g., 0.2 - 0.5mm] |

| Outer Sheath Material | FEP (optional, if applicable) |

| Outer Sheath Color Coding |

Positive: Red Negative: Blue (standard color coding, can be customized) |

| Operating Temperature Range |

Continuous: – 60°C to [high - temperature limit, e.g., 200°C] Short – term peak: up to [higher peak temperature, e.g., 250°C] |

| Resistance per Unit Length | Varies according to conductor gauge, for example, [give typical resistance value for a specific gauge, e.g., for AWG 20: 16.19 Ω/km at 20°C] |

Chemical Composition (Relevant Parts)

- Iron (in positive conductor): Mainly iron, with trace amounts of other elements to ensure appropriate electrical and mechanical properties.

- Constantan (in negative conductor): Typically contains approximately 60% copper and 40% nickel, with small amounts of other alloying elements for stability.

- FEP Insulation: Consists of a fluoropolymer with a high proportion of fluorine and carbon atoms, providing its unique properties.

Product Specifications

| Item | Specification |

|---|---|

| Wire Diameter | Varies based on conductor gauge, for example, AWG 18 wire diameter is approximately [specify diameter value, e.g., 1.02mm] (customizable) |

| Length | Available in standard lengths such as 100m, 200m, 500m rolls (custom lengths can be provided) |

| Packaging | Spool – wound, with options for plastic spools or cardboard spools, and can be further packed in cartons or pallets for shipping |

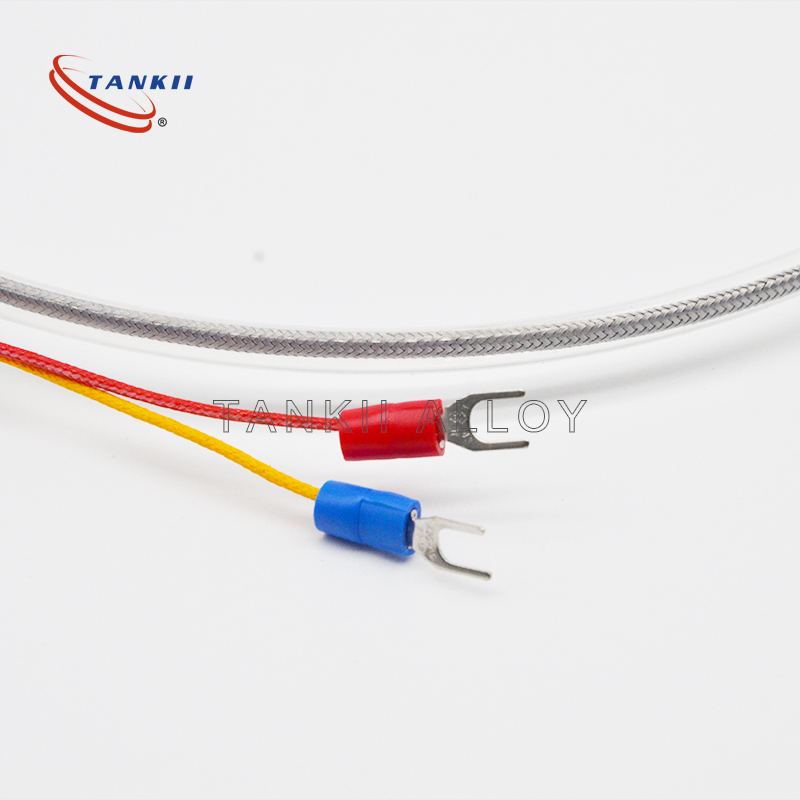

| Connection Terminals | Optional pre – crimped terminals, such as bullet connectors, spade connectors, or bare – ended for custom termination (can be customized as per requirements) |

| OEM Support | Available, including custom printing of logos, labels, and specific product markings on the wire or packaging |

We also supply other types of thermocouple extension wires, such as K – type, T – type, etc., along with related accessories like terminal blocks and junction boxes. Free samples and detailed technical datasheets are available upon request. Custom product specifications, including insulation materials, conductor gauges, and packaging, can be tailored to meet specific application needs.

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top