High Performance Quartz Tube Heaters – Karma Wire for Precision Resistors (0.02mm, 0.03mm, 0.04mm) – TANKII

High Performance Quartz Tube Heaters – Karma Wire for Precision Resistors (0.02mm, 0.03mm, 0.04mm) – TANKII Detail:

Karma Wire for Precision Resistors (0.02mm, 0.03mm, 0.04mm)

1. Karma alloy

Karma alloy is made up of copper, nickel, Aluminum and Iron as the main components. The resistivity is 2~3 times higher than MENTONG. It has lower temperature coefficient of resistance(TCR), lower thermal EMF versus copper, good permanence of resistance for a long period of time and strong anti-oxidation. Its working temperature range is wider than MENTONG (-60~300ºC). It is suitable for making fine precision resistance elements and strain.

2. Karma size

Wire: 0.01mm-10mm

Ribbon: 0.05*0.2mm-2.0*6.0mm

Strip: 0.5*5.0mm-5.0*250mm

3.Karma Property

| name | code | Main Composition (%) | Standard | |||

| Cr | Al | Fe | Ni | |||

| Karma | 6J22 | 19~21 | 2.5~3.2 | 2.0~3.0 | bal. | JB/T 5328 |

| Name | Code | (20ºC) Resistivity (μΩ.m) |

(20ºC) Temp. Coeff.Of Resistance (αX10-6/ºC) |

(0~100ºC) ThermalEMF vs.Copper (μv/ºC) |

Max.working Temp.(ºC) |

(%) Elongation |

(N/mm2) Tensile Strength |

Standard |

| Karma | 6J22 | 1.33±0.07 | ≤±20 | ≤2.5 | ≤300 | >7 | ≥780 | JB/T 5328 |

4. Distinctive features of Karma resistance wire

1) Starting with Nickel Chromium electric heat wire Class 1, we replaced some of the Ni with

Al and other elements, and thus achieved a precision resistance material with improved

resistance temperature coefficient and heat electromotive force against copper.

With the addition of Al, we have succeeded in making volume resistivity 1.2 times greater

than Nickel Chromium electric heat wire Class 1 and the tensile strength 1.3 times greater.

2) The secondary temperature coefficient β of Karmalloy wire KMW is very small, - 0.03 × 10-6/ K2,

and the resistance temperature curve turns out to be almost a straight line within a wide

temperature range.

Therefore, the temperature coefficient is set to be the average temperature coefficient between

23 ~ 53 °C, but 1 × 10-6/K, the average temperature coefficient between 0 ~ 100 °C, also may

be adopted for the temperature coefficient.

3) Electromotive force against copper between 1 ~ 100 °C is also small, below + 2 μV/K, and

exhibits excellent stability over a period of many years.

4) If this is to be used as a precision resistance material, low temperature heat treatment is

required to eliminate processing distortions just as in the case of Manganin wire CMW.

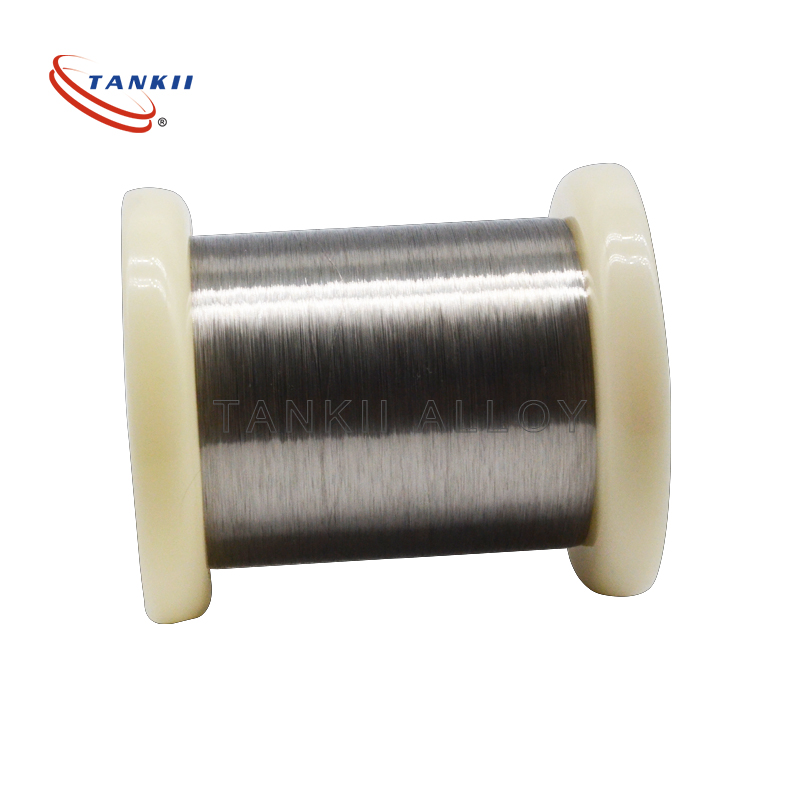

Product detail pictures:

Related Product Guide:

Our merchandise are commonly identified and dependable by end users and will meet continually altering financial and social desires for High Performance Quartz Tube Heaters – Karma Wire for Precision Resistors (0.02mm, 0.03mm, 0.04mm) – TANKII , The product will supply to all over the world, such as: Switzerland, Pakistan, Montpellier, Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we provide our clients with high quality products and excellent service. Please feel free to contact us for further information.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top