High Quality for Mws-875 - Iron Chrome Aluminum Resistance Alloys – TANKII

High Quality for Mws-875 - Iron Chrome Aluminum Resistance Alloys – TANKII Detail:

Iron Chrome Aluminum (FeCrAl) alloys are high-resistance materials typically used in applications with maximum operating temperatures up to 1,400°C (2,550°F).

These Ferritic alloys are known to have higher surface loading capability, higher resistivity and lower density than Nickel Chrome (NiCr) alternatives which can translate to less material in application and weight savings. The higher maximum operating temperatures can also lead to longer element life. Iron Chrome Aluminum alloys form a light grey Aluminum Oxide (Al2O3) at temperatures above 1,000°C (1,832°F) which increases corrosion resistance as well as acts as an electrical insulator. The oxide formation is considered self-insulating and protects against short circuiting in the event of metal to metal contact. Iron Chrome Aluminum alloys have lower mechanical strength when compared to Nickel Chrome materials as well as lower creep strength.

Specification of Cold-drawing Round Type heating wire

|

Diameter(mm) |

Tolerance(mm) |

Diameter(mm) |

Tolerance(mm) |

|

0.03-0.05 |

±0.005 |

>0.50-1.00 |

±0.02 |

|

>0.05-0.10 |

±0.006 |

>1.00-3.00 |

±0.03 |

|

>0.10-0.20 |

±0.008 |

>3.00-6.00 |

±0.04 |

|

>0.20-0.30 |

±0.010 |

>6.00-8.00 |

±0.05 |

|

>0.30-0.50 |

±0.015 |

>8.00-12.0 |

±0.4 |

Specification of Cold-drawing Strip Type heating wire

|

Thickness(mm) |

Tolerance(mm) |

Width(mm) |

Tolerance(mm) |

|

0.05-0.10 |

±0.010 |

5.00-10.0 |

±0.2 |

|

>0.10-0.20 |

±0.015 |

>10.0-20.0 |

±0.2 |

|

>0.20-0.50 |

±0.020 |

>20.0-30.0 |

±0.2 |

|

>0.50-1.00 |

±0.030 |

>30.0-50.0 |

±0.3 |

|

>1.00-1.80 |

±0.040 |

>50.0-90.0 |

±0.3 |

|

>1.80-2.50 |

±0.050 |

>90.0-120.0 |

±0.5 |

|

>2.50-3.50 |

±0.060 |

>120.0-250.0 |

±0.6 |

|

Alloy Type |

Diameter |

Resistivity |

Tensile |

Elongation(%) |

Bending |

Max.Continuous |

Working Life |

|

1Cr13Al4 |

0.03-12.0 |

1.25±0.08 |

588-735 |

>16 |

>6 |

950 |

>10000 |

|

0Cr15Al5 |

1.25±0.08 |

588-735 |

>16 |

>6 |

1000 |

>10000 |

|

|

0Cr25Al5 |

1.42±0.07 |

634-784 |

>12 |

>5 |

1300 |

>8000 |

|

|

0Cr23Al5 |

1.35±0.06 |

634-784 |

>12 |

>5 |

1250 |

>8000 |

|

|

0Cr21Al6 |

1.42±0.07 |

634-784 |

>12 |

>5 |

1300 |

>8000 |

|

|

1Cr20Al3 |

1.23±0.06 |

634-784 |

>12 |

>5 |

1100 |

>8000 |

|

|

0Cr21Al6Nb |

1.45±0.07 |

634-784 |

>12 |

>5 |

1350 |

>8000 |

|

|

0Cr27Al7Mo2 |

0.03-12.0 |

1.53±0.07 |

686-784 |

>12 |

>5 |

1400 |

>8000 |

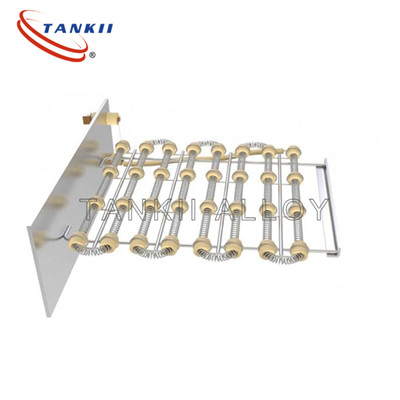

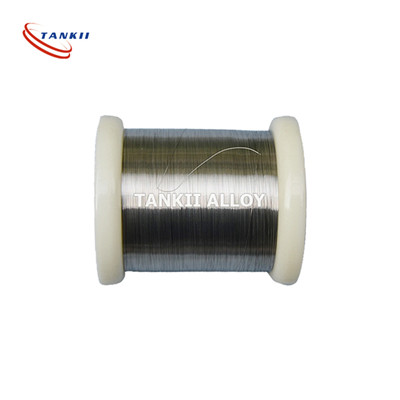

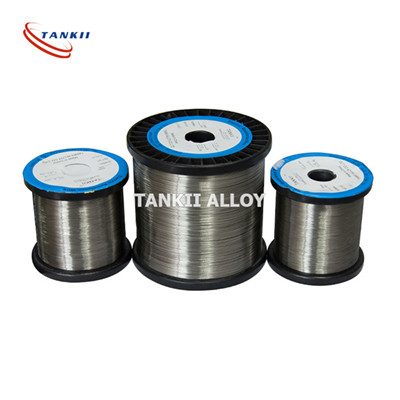

Product detail pictures:

Related Product Guide:

We insist over the principle of development of 'High top quality, Performance, Sincerity and Down-to-earth working approach' to supply you with exceptional services of processing for High Quality for Mws-875 - Iron Chrome Aluminum Resistance Alloys – TANKII , The product will supply to all over the world, such as: Jakarta, San Diego, Oman, Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.