High reputation Alloy 875 - Iron Chrome Aluminum Resistance Alloys – TANKII

High reputation Alloy 875 - Iron Chrome Aluminum Resistance Alloys – TANKII Detail:

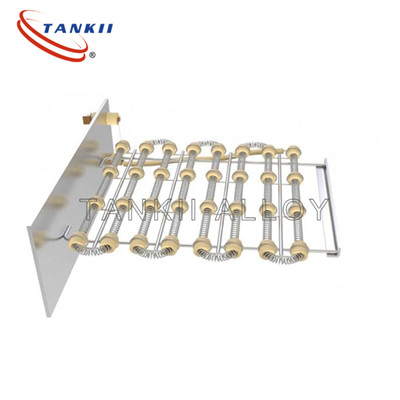

Iron Chrome Aluminum (FeCrAl) alloys are high-resistance materials typically used in applications with maximum operating temperatures up to 1,400°C (2,550°F).

These Ferritic alloys are known to have higher surface loading capability, higher resistivity and lower density than Nickel Chrome (NiCr) alternatives which can translate to less material in application and weight savings. The higher maximum operating temperatures can also lead to longer element life. Iron Chrome Aluminum alloys form a light grey Aluminum Oxide (Al2O3) at temperatures above 1,000°C (1,832°F) which increases corrosion resistance as well as acts as an electrical insulator. The oxide formation is considered self-insulating and protects against short circuiting in the event of metal to metal contact. Iron Chrome Aluminum alloys have lower mechanical strength when compared to Nickel Chrome materials as well as lower creep strength.

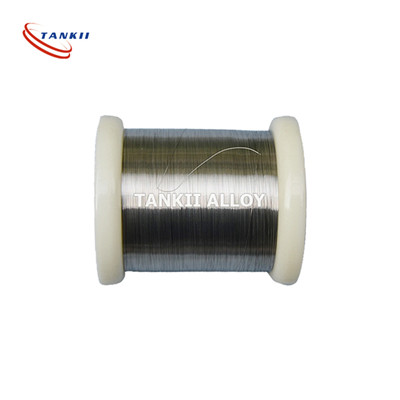

Specification of Cold-drawing Round Type heating wire

|

Diameter(mm) |

Tolerance(mm) |

Diameter(mm) |

Tolerance(mm) |

|

0.03-0.05 |

±0.005 |

>0.50-1.00 |

±0.02 |

|

>0.05-0.10 |

±0.006 |

>1.00-3.00 |

±0.03 |

|

>0.10-0.20 |

±0.008 |

>3.00-6.00 |

±0.04 |

|

>0.20-0.30 |

±0.010 |

>6.00-8.00 |

±0.05 |

|

>0.30-0.50 |

±0.015 |

>8.00-12.0 |

±0.4 |

Specification of Cold-drawing Strip Type heating wire

|

Thickness(mm) |

Tolerance(mm) |

Width(mm) |

Tolerance(mm) |

|

0.05-0.10 |

±0.010 |

5.00-10.0 |

±0.2 |

|

>0.10-0.20 |

±0.015 |

>10.0-20.0 |

±0.2 |

|

>0.20-0.50 |

±0.020 |

>20.0-30.0 |

±0.2 |

|

>0.50-1.00 |

±0.030 |

>30.0-50.0 |

±0.3 |

|

>1.00-1.80 |

±0.040 |

>50.0-90.0 |

±0.3 |

|

>1.80-2.50 |

±0.050 |

>90.0-120.0 |

±0.5 |

|

>2.50-3.50 |

±0.060 |

>120.0-250.0 |

±0.6 |

|

Alloy Type |

Diameter |

Resistivity |

Tensile |

Elongation(%) |

Bending |

Max.Continuous |

Working Life |

|

1Cr13Al4 |

0.03-12.0 |

1.25±0.08 |

588-735 |

>16 |

>6 |

950 |

>10000 |

|

0Cr15Al5 |

1.25±0.08 |

588-735 |

>16 |

>6 |

1000 |

>10000 |

|

|

0Cr25Al5 |

1.42±0.07 |

634-784 |

>12 |

>5 |

1300 |

>8000 |

|

|

0Cr23Al5 |

1.35±0.06 |

634-784 |

>12 |

>5 |

1250 |

>8000 |

|

|

0Cr21Al6 |

1.42±0.07 |

634-784 |

>12 |

>5 |

1300 |

>8000 |

|

|

1Cr20Al3 |

1.23±0.06 |

634-784 |

>12 |

>5 |

1100 |

>8000 |

|

|

0Cr21Al6Nb |

1.45±0.07 |

634-784 |

>12 |

>5 |

1350 |

>8000 |

|

|

0Cr27Al7Mo2 |

0.03-12.0 |

1.53±0.07 |

686-784 |

>12 |

>5 |

1400 |

>8000 |

Product detail pictures:

Related Product Guide:

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for High reputation Alloy 875 - Iron Chrome Aluminum Resistance Alloys – TANKII , The product will supply to all over the world, such as: Thailand, Liberia, Southampton, To win customers' confidence, Best Source has set up a strong sales and after-sales team to provide the best product and service. Best Source abides by the idea of "Grow with customer" and philosophy of "Customer-oriented" to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let's grow together!

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top