Welcome to our websites!

In Stock High Quality ТБ2013/TM-2/108SP Bimetallic Strip for Temp Control

Product Description

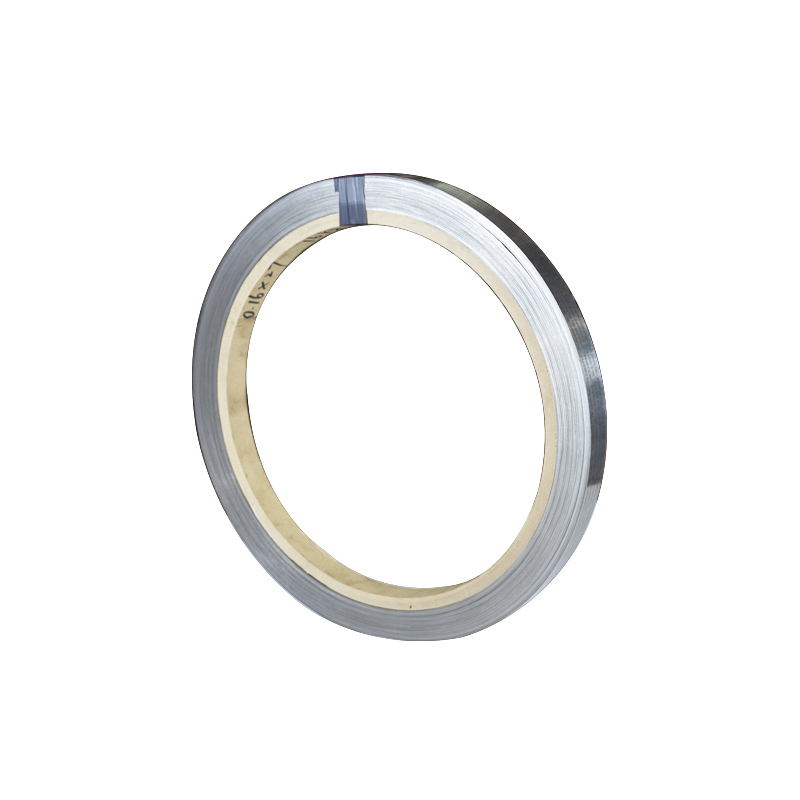

ТБ2013/TM-2/108SP Bimetallic Strip

Product Overview

ТБ2013/TM-2/108SP bimetallic strip, a high-performance functional composite developed and manufactured by Tankii Alloy Material, is a specialized grade optimized for medium-to-high temperature thermal actuation scenarios. Composed of two dissimilar alloys with precisely controlled thermal expansion coefficients—bonded via Huona’s proprietary hot-rolling diffusion technology—this strip integrates three core advantages: stable temperature responsiveness, excellent mechanical fatigue resistance, and broad environmental adaptability. Unlike generic bimetallic strips, the ТБ2013/TM-2/108SP grade is tailored to balance thermal sensitivity and structural strength, making it ideal for industrial thermostats, motor overheat protectors, and precision temperature compensation components in harsh operating environments (e.g., high humidity, vibration).

Standard Designations & Core Composition

- Product Grade: ТБ2013/TM-2/108SP

- Composite Structure: Typically consists of a “high-expansion layer” and a “low-expansion layer” ; interfacial bonding strength ≥140 MPa

- Compliant Standards: Adheres to GOST 28561-90 (Russian standard for bimetallic strips) and IEC 60694 for thermal control components; compatible with EU RoHS requirements

- Manufacturer: Tankii Alloy Material, certified to ISO 9001 and ISO 14001, with in-house alloy formulation and composite bonding capabilities to match the grade’s specific performance requirements

Key Advantages (vs. Generic Bimetallic Strips)

ТБ2013/TM-2/108SP stands out for its application-focused performance, addressing pain points in industrial and harsh-environment use:

- Broad Temperature Adaptability: Operates stably in -50℃ to 250℃ (continuous use), with short-term resistance up to 300℃—surpassing standard bimetallic strips (limited to ≤200℃) and suitable for high-temperature industrial scenarios (e.g., engine compartment sensors).

- Low Thermal Hysteresis: Hysteresis error ≤3℃ (between heating and cooling actuation points) at 150℃—critical for precision temperature control (e.g., industrial oven thermostats) where repeated on/off cycles require consistent thresholds.

- Strong Fatigue Resistance: Withstands ≥15,000 thermal cycles (-50℃ to 250℃) without interfacial delamination or performance decay—3× longer service life than low-grade strips, reducing maintenance costs for long-service equipment (e.g., HVAC systems).

- Vibration & Corrosion Resistance: Transverse tensile strength ≥460 MPa ensures structural stability under vibration (compatible with IEC 60068-2-6 vibration tests); optional zinc-plating provides 96-hour salt spray resistance (ASTM B117) for humid or corrosive environments (e.g., marine equipment).

- Consistent Dimensional Precision: Available in common thicknesses (0.15mm–0.8mm) and widths (10mm–200mm) with tolerance ≤±0.005mm (thickness) and ≤±0.1mm (width)—enabling automated stamping and integration into standard industrial components.

Technical Specifications

| Attribute | Value (Typical) |

|---|---|

| Thickness Range | 0.15mm – 0.8mm (custom up to 1.2mm) |

| Width Range | 10mm – 200mm (standard widths: 15mm, 20mm, 27mm) |

| Length per Roll | 50m – 300m (cut-to-length available: ≥100mm) |

| Thermal Expansion Coefficient Ratio (High/Low Layer) | ~4:1 |

| Operating Temperature Range | -50℃ to 250℃ (continuous); Short-term: up to 300℃ (≤1 hour) |

| Actuation Temperature Deviation | ±2℃ (at rated actuation point, 80℃–200℃) |

| Interfacial Shear Strength | ≥140 MPa |

| Tensile Strength (Transverse) | ≥460 MPa |

| Elongation (25℃) | ≥14% |

| Resistivity (25℃) | 0.20 – 0.35 Ω·mm²/m |

| Surface Roughness (Ra) | ≤0.8μm (mill finish); ≤0.4μm (polished finish, optional) |

Product Specifications

| Item | Specification |

|---|---|

| Surface Finish | Mill finish (oxide-free) or zinc-plated/nickel-plated (for enhanced corrosion resistance) |

| Flatness | ≤0.1mm/m (critical for uniform thermal deformation and stamping accuracy) |

| Machinability | Compatible with CNC stamping, laser cutting, and bending; no interfacial cracking during processing (minimum bending radius ≥3× thickness) |

| Bonding Quality | 100% interfacial bonding (no voids >0.1mm², verified via X-ray inspection and ultrasonic testing) |

| Packaging | Vacuum-sealed in moisture-proof aluminum foil bags with desiccants; wooden spools (for rolls) or anti-bend cartons (for cut sheets) to prevent deformation |

| Customization | Adjustment of actuation temperature (60℃–220℃), surface coating, pre-stamped shapes (per customer CAD files), and non-standard thickness/width |

Typical Applications

- Industrial Temperature Control: Thermostats for industrial ovens, boilers, and HVAC systems; temperature regulators for plastic molding machines (operating at 120℃–200℃).

- Overheat Protection: Thermal circuit breakers for electric motors (e.g., industrial pumps, compressors) and power transformers—prevents burnout by disconnecting circuits at 150℃–250℃.

- Automotive & Marine: Temperature sensors and protectors for engine compartments (automotive) and marine equipment (resistant to vibration and saltwater corrosion).

- Precision Instruments: Temperature-compensating elements for pressure gauges, flow meters, and MEMS sensors—offsets thermal expansion errors to maintain measurement accuracy.

- Household & Commercial Appliances: Overheat protectors for electric water heaters, air conditioners, and commercial refrigerators (stable performance in high-humidity environments).

Tankii Alloy Material implements strict quality control for ТБ2013/TM-2/108SP bimetallic strips: each batch undergoes interfacial shear testing, 1000-cycle thermal stability testing, dimensional inspection (laser micrometry), and actuation temperature calibration. Free samples (100mm×20mm) and detailed performance reports (including thermal curvature vs. temperature curves) are available upon request. Our technical team provides tailored support—such as alloy layer optimization for specific operating temperatures and compatibility guidance with industrial assembly processes—to ensure the strip meets the exact needs of Eurasian and global industrial applications.

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top