Manufacturer for Mechanical Components - Pure nickel resistance wire – TANKII

Manufacturer for Mechanical Components - Pure nickel resistance wire – TANKII Detail:

Pure nickel resistance wire

Pure nickel wire has the characteristics of good strength at high temperature, good plasticity, poor thermal conductivity and high resistivity.

Application areas

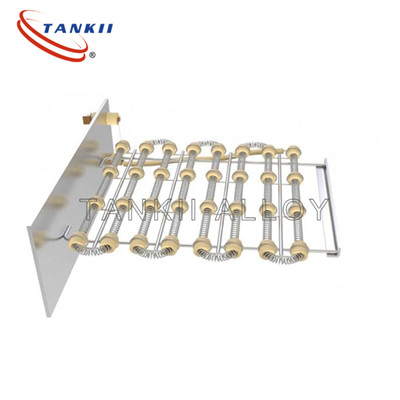

Wire: Sputter Targets, evaporation pellets, regulator coil in glow plugs of diesel engines; litz wire for current conduction under elevated temperatures and in aggressive environments, Pre material for thin wire manfacturing, Ni wire mesh, Thermal Spraying, Coating layer for corrosion protection from alkalis; salt spray; molten salt and reduciing chemicals; coating layer for high temperature resistance; corrosion protection at high temperatures; coating layer for membrane walls of power plants

Processing history

For producing wire, the 6 mm hot rolled thick plates are cut into 6 mm wide sticks. The sticks are frontally welded. Afterwards the raw wire can be treated in the same way as hot rolled wire produced by melt metallurgy. accordingly, the wire is drawn to the desired dimensions through cold drawing and intermediate annealing.

Surface Finish

Blank/Bare/bright surface

| Pure nickel resistance wire | |

| Grade | Ni200, Ni201, Ni205 |

| Size | wire:φ0.1-12mm |

| Features | Good mechanical strength, corrosion resistance and high heat resistance strength. It is suitable for making vacuum devices, electronic instrument components, and filters for chemical production of strong alkalis. |

| Application | radio, electric light source, machinery manufacturing, chemical industry, and is an important structural material in vacuum electronic devices. |

Chemical Composition (Wt.%)

|

Nickel Grade |

Ni+Co |

Cu |

Si |

Mn |

C |

Cr |

S |

Fe |

Mg |

|

≥ |

≤ |

||||||||

|

Ni201 |

99.2 |

.25 |

.3 |

.35 |

.02 |

.2 |

.01 |

.3 |

- |

|

Ni200 |

99.0 |

.25 |

.3 |

.35 |

.15 |

.2 |

.01 |

.3 |

- |

Mechanical Properties

|

Grade |

Condition |

Diameter(mm) |

Tensile Strength N/mm2, Min |

Elongation, %,Min |

|

Ni200 |

M |

0.03-0.20 |

373 |

15 |

|

0.21-0.48 |

343 |

20 |

||

|

0.50-1.00 |

314 |

20 |

||

|

1.05-6.00 |

294 |

25 |

||

|

1/2Y |

0.10-0.50 |

686-883 |

- |

|

|

0.53-1.00 |

588-785 |

- |

||

|

1.05-5.00 |

490-637 |

- |

||

|

Y |

0.03-0.09 |

785-1275 |

- |

|

|

0.10-0.50 |

735-981 |

- |

||

|

0.53-1.00 |

686-883 |

- |

||

|

1.05-6.00 |

539-834 |

- |

||

|

Ni201 |

M |

0.03-0.20 |

422 |

15 |

|

0.21-0.48 |

392 |

20 |

||

|

0.50-1.00 |

373 |

20 |

||

|

1.05-6.00 |

343 |

25 |

||

|

1/2Y |

0.10-0.50 |

785-981 |

- |

|

|

0.53-1.00 |

686-834 |

- |

||

|

1.05-5.00 |

539-686 |

- |

||

|

Y |

0.03-0.09 |

883-1325 |

- |

|

|

0.10-0.50 |

834-1079 |

- |

||

|

0.53-1.00 |

735-981 |

- |

||

|

1.05-6.00 |

637-883 |

- |

Dimension and Tolerance (mm)

|

Diameter |

0.025-0.03 |

>0.03-0.10 |

>0.10-0.40 |

>0.40-0.80 |

>0.80-1.20 |

>1.20-2.00 |

|

Tolerance |

±0.0025 |

±0.005 |

±0.006 |

±0.013 |

±0.02 |

±0.03 |

Remarks:

1). Condition: M=Soft.1/2Y=1/2Hard, Y= Hard

2). If you have resistivity demand, also we melt for you.

Product detail pictures:

Related Product Guide:

Our firm aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine regularly for Manufacturer for Mechanical Components - Pure nickel resistance wire – TANKII , The product will supply to all over the world, such as: Wellington, Argentina, Bulgaria, Our company always concentrate on the development of the international market. We have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top