Welcome to our websites!

Nch (R) W1 Stranded Nichrome Resistance Wire for Heating Cable

Nch (R) W1 Stranded Nichrome Resistance Wire for Heating Cable

Description

| Alloy | Standard Strand Construction, mm | Resistance,Ω/m | Strand Diameter Nominal, mm | Meter per Kilo |

| NiCr 80/20 | 19×0.544 | 0.233-0.269 | 26 | |

| NiCr 80/20 | 19×0.61 | 0.205-0.250 | ||

| NiCr 80/20 | 19×0.523 | 0.276-0.306 | 2.67 | 30 |

| NiCr 80/20 | 19×0.574 | 2.87 | 25 | |

| NiCr 80/20 | 37×0.385 | 0.248-0.302 | 2.76 | 26 |

| NiCr 60/15 | 19×0.508 | 0.286-0.318 | ||

| NiCr 60/15 | 19×0.523 | 0.276-0.304 | 30 | |

| Ni | 19×0.574 | 0.020-0.027 | 2.87 | 21 |

Details

| Propertes/Grade | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

| Main Chemical composition | Ni | Rest | Rest | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe | ≤ 1.0 | ≤ 1.0 | Rest | Rest | Rest | |

| Max. continuous service temp. of element | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Resistivity at 20oC (μ Ω · m) | 1.09 | 1.18 | 1.12 | 1.04 | 1.04 | |

| Density (g/cm3) | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Thermal conductivity(KJ/m· h· oC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Coefficient of lines expansion(α × 10-6/oC) | 18 | 17 | 17 | 19 | 19 | |

| Melting point (approx. )( oC) | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Elongation at rupture (%) | > 20 | > 20 | > 20 | > 20 | > 20 | |

| Micrographic structure | austenite | austenite | austenite | austenite | austenite | |

| Magnetic properties | nonmagnetic | nonmagnetic | nonmagnetic | nonmagnetic | nonmagnetic | |

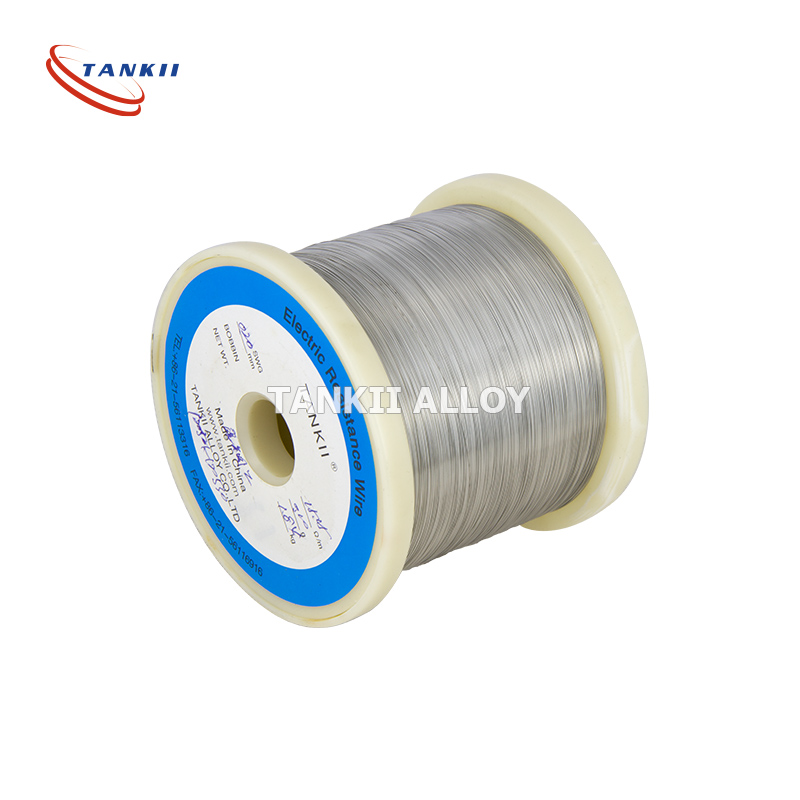

| Chemical Composition | Nickel , Chrome |

| Condition | Bright/Acid white/Oxidied Color |

| Grade | Ni80Cr20, Ni70/30, Ni60Cr15, Ni60Cr23, Ni35Cr20Fe, Ni30Cr20 Ni80, Ni70,Ni60, Ni40, |

| Advantage | Nichrome’s metallurgical structure confers them a very good plasticity when cold. |

| Characteristics | Stable performance; Anti-oxidation; Corrosion resistance; High temperature stability; Excellent coil-forming ability; Uniform and beautiful surface condition without spots. |

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top