For the resistance wire, the power of our resistance can be determined according to the resistance of the resistance wire. The greater its power, it is possible that many people do not know how to choose the resistance wire, and there is not much knowledge about the resistance wire. , Xiaobian will explain to everyone.

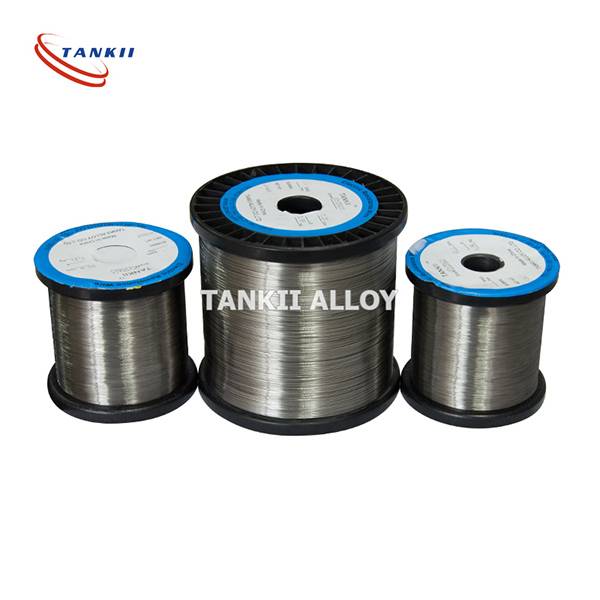

Resistance wire is the most common kind of heating element. Its function is to generate heat after energization and convert electrical energy into heat. Resistance wire has a wide range of applications. Many commonly used electric heating devices use resistance wire as heating element. Therefore, resistance wire is used in medical, chemical, electronics, electrical, metallurgical machinery, ceramic glass processing and other industries.

1. The working principle of resistance wire

The working principle of resistance wire is the same as that of other metal heating elements, and it is the electric heating phenomenon after metal is energized. Electric heating means that after the current passes through the conductor, the current will generate a certain amount of heat and be transferred by the conductor. The resistance wire itself is a metal conductor, which will emit heat and provide thermal energy after being energized.

2. Classification of resistance wire

The types of resistance wire are divided according to the chemical element content and organizational structure of the resistance wire. There are iron-chromium-aluminum alloy resistance wires and nickel-chromium alloy resistance wires. As electric heating elements, these two kinds of resistance wires have different functional characteristics.

3. the characteristics of resistance wire

The resistance wire is characterized by high temperature resistance, fast heating, long service life, stable resistance, small power deviation, uniform thread pitch after stretching, and bright and clean surface. It is widely used in small electric furnaces, muffle furnaces, heating and air conditioning equipment, various ovens, Electric heating tubes and household appliances, etc. Various non-standard industrial and civil furnace bars can be designed and produced according to user needs.

4. the advantages and disadvantages of iron-chromium-aluminum alloy resistance wire

The iron-chromium-aluminum alloy resistance wire has the advantage of high operating temperature. The experiment shows that the maximum operating temperature of the iron-chromium-aluminum alloy resistance wire can reach 1400°C. The iron-chromium-aluminum alloy resistance wire has long service life, high resistivity, high surface compounding, and good oxidation resistance.

The disadvantage of iron-chromium-aluminum alloy resistance wire is its low strength in high temperature environments. As the temperature increases, the plasticity of the iron-chromium-aluminum alloy resistance wire will increase, which means that the iron-chromium-aluminum alloy resistance wire is prone to deformation at high temperatures. And it is not easy to repair after deformation.

5.the advantages and disadvantages of nickel-chromium alloy resistance wire

The advantages of nickel-chromium alloy resistance wire are high strength in high temperature environment, long-term high temperature operation is not easy to deform, and it is not easy to change the structure, and the normal temperature plasticity of nickel-chromium alloy resistance wire is good, and the repair after deformation is relatively simple. In addition, nickel-chromium alloy resistance wire has high emissivity, non-magnetic, good corrosion resistance and long service life.

The disadvantage of nickel-chromium alloy resistance wire is that the operating temperature cannot reach the level of the previous resistance wire. The manufacture of nickel-chromium alloy resistance wire requires the use of nickel. The price of this metal is higher than that of iron, chromium and aluminum. Therefore, the manufacturing cost of nickel-chromium alloy resistance wire is relatively high, which is not conducive to cost control.

Post time: Oct-30-2020