OEM Factory for N6 - Nickel chrome alloy wire Ni70Cr30 – TANKII

OEM Factory for N6 - Nickel chrome alloy wire Ni70Cr30 – TANKII Detail:

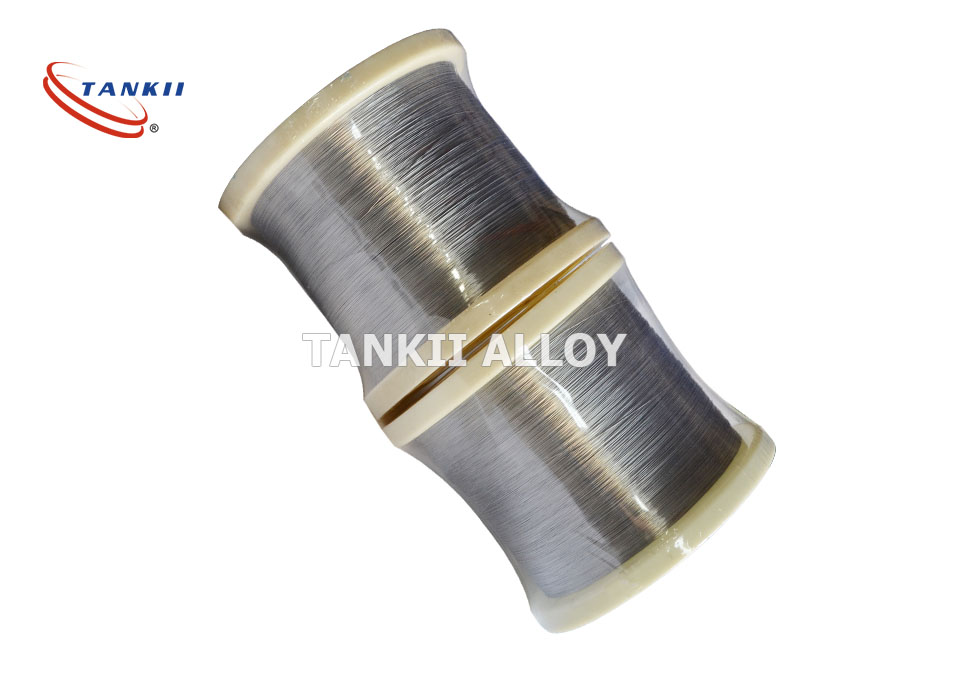

Nickel chrome alloy wire Ni70Cr30

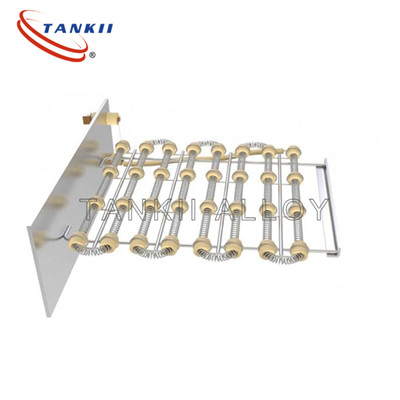

Cr30Ni70 Nichrome Alloy Eletrothermal Coil Strip,Sable Resistance For Heating Element,

NiCr70/30

Nickel chromium alloy with iron resistance electrothermal high resistivity, surface body sexual well. At high temperature and high intensity,

and a good performance and processing may welding nature widely used metallurgical, electrical, mechanical components and electrical

manufacturing industries for doing heat resistance material.

NiCr Type:Cr20Ni80,Cr15Ni60, Cr20Ni35, Cr20Ni30, Cr25Ni20 etc.Series electric flat belt, electric fire wire.

3.Product size:

Thickness : 0.02—-4.0mm

Width: 2.5—-250mm

Standard:GB1234-95

Bright and Smooth surface

Ni70Cr30

Chemical Content, %

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Other |

| Max | |||||||||

| 0.08 | 0.02 | 0.015 | 0.60 | 0.75~1.60 | 28.0~31.0 | Bal. | Max 0.50 | Max 1.0 | - |

Mechanical Properties

|

Max Continuous Service Temperature: Resisivity ( 20ºC)/Ω·m:: Density: |

1250ºC 1.18 +/-0.05 (Dia: <0.5mm) 1.20+/-0.05 (Dia: ≥0.50 mm) 8.1 g/cm3 45.2 KJ/m·h·ºC 17×10-6/ºC (20ºC~1000ºC) 1380ºC Min 20% Austenite nonmagnetic |

| Type | Cr20Ni80 | Cr15Ni60 | Cr30Ni70 | Cr20Ni35 | Cr20Ni30 | |

| Main chemical composition | Ni | Rest | 55.0~61.0 | Rest | 34.0~37.0 | 30.0~34.0 |

| Cr | 20.0~23.0 | 15.0~18.0 | 28.0~31.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | ≤1 | Rest | ≤1 | Rest | Rest | |

| Maximal Temperature(ºC) | 1200 | 1150 | 1250 | 1100 | 1100 | |

| Resistance Temperature correction coefficient.(CT) | 1.09±0.05 | 1.11±0.05 | 1.18±0.05 | 1.04±0.05 | 1.06±0.05 | |

| Melting point (ºC) | 1400 | 1390 | 1380 | 1390 | 1390 | |

| Resistivityρ20ºC(10-6Ω.m) | 800ºC | 1.008 | 1.078 | 1.028 | 1.188 | 1.173 |

| 1000ºC | 1.014 | 1.095 | 1.033 | 1.219 | 1.201 | |

| 1200ºC | 1.025 | 1.043 | ||||

| Fast life value | Tem.(ºC) | 1175 | 1100 | 1200 | 1050 | 1050 |

| hour(h) | ≥110 | ≥100 | ≥110 | ≥100 | ≥100 | |

| Specific gravity(g/cm3) | 8.40 | 8.2 | 8.1 | 7.90 | 7.90 | |

| Elongation(%) | ≥25 | ≥25 | ≥20 | ≥20 | ≥20 | |

| Thermal(kj/m.h.ºC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Specific heat(20ºC)j/g.ºC | 0.440 | 0.494 | 0.461 | 0.500 | 0.500 | |

| Extend strength(20~1000ºC)α*10-6ºC | 18.0 | 17.0 | 17.1 | 19.0 | 19.0 | |

| Tensile strength(kg/mm2) | >85 | >85 | >85 | >85 | >85 | |

| Repeatedly bending(F/R) | >12 | >12 | >12 | >12 | >12 | |

| Microstructure | Austenitic | Austenitic | Austenitic | Austenitic | Austenitic | |

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer superb companies to just about every buyer, but also are ready to receive any suggestion offered by our shoppers for OEM Factory for N6 - Nickel chrome alloy wire Ni70Cr30 – TANKII , The product will supply to all over the world, such as: Naples, Nepal, Moscow, Our company promises: reasonable prices, short production time and satisfactory after-sales service, we also welcome you to visit our factory at any time you want. Wish we have a pleasant and long terms business together!!!

A good manufacturers, we have cooperated twice, good quality and good service attitude.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top