Welcome to our websites!

OEM Manufacturer Hai-30 - Phosphor Bronze-C/Ercusn-C/Scu5210 Copper Alloys Welding Wire – TANKII

OEM Manufacturer Hai-30 - Phosphor Bronze-C/Ercusn-C/Scu5210 Copper Alloys Welding Wire – TANKII Detail:

Chemical composition:

| Executive standard |

Classification number |

Alloy number |

Cu | AI | Fe | Mn | Ni | P | Pb | Si | Sn | Zn | Total amount of other elements |

| ISO24373 | Cu5210 | CuSn8P | bal. | - | 0.1 | - | 0.2 | 0.01-0.4 | 0.02 | - | 7.5-8.5 | 0..2 | 0.2 |

| GB/T9460 | SCu5210 | CuSn8P | bal. | - | max0.1 | - | max0.2 | 0.01-0.4 | max0.02 | - | 7.5-8.5 | max0.2 | max0.2 |

| BS EN14640 | Cu5210 | CuSn9P | bal. | - | 0.1 | - | - | 0.01-0.4 | 0.02 | - | 7.5-8.5 | 0.2 | 0.5 |

| AWS A5.7 | C52100 | ERCuSn-C | bal. | 0.01 | 0.10 | - | - | 0.10-0.35 | 0.02 | - | 7.5-8.5 | 0.2 | 0.50 |

Physical properties of materials:

| Density | Kg/m3 | 8.8 |

| Melting range | ºC | 875-1025 |

| Thermal conductivity | W/m.K | 66 |

| Electrical conductivity | S.m/mm2 | 6-8 |

| Coefficient of thermal expansion | 10-6/K(20-300ºC) | 18.5 |

Standard values of the weld metal:

| Elongation | % | 20 |

| Tensile strength | N/mm² | 260 |

| Notched bar impact work | J | 32 |

| Brinell hardness | HB 2.5/62.5 | 80 |

Applications:

Copper tin alloy of higher tin percentage-increased hardness for overlay welding.Particularly suitable for welding of copper materials, like copper,tin bronzes,especially used for joining of copper zinc alloys and steels.Suitable for repair welding of cast bronzes and for oven soldering.For multilayer welding on steel,pulsed arc welding is recommended.For large work pieces preheating is recommended.

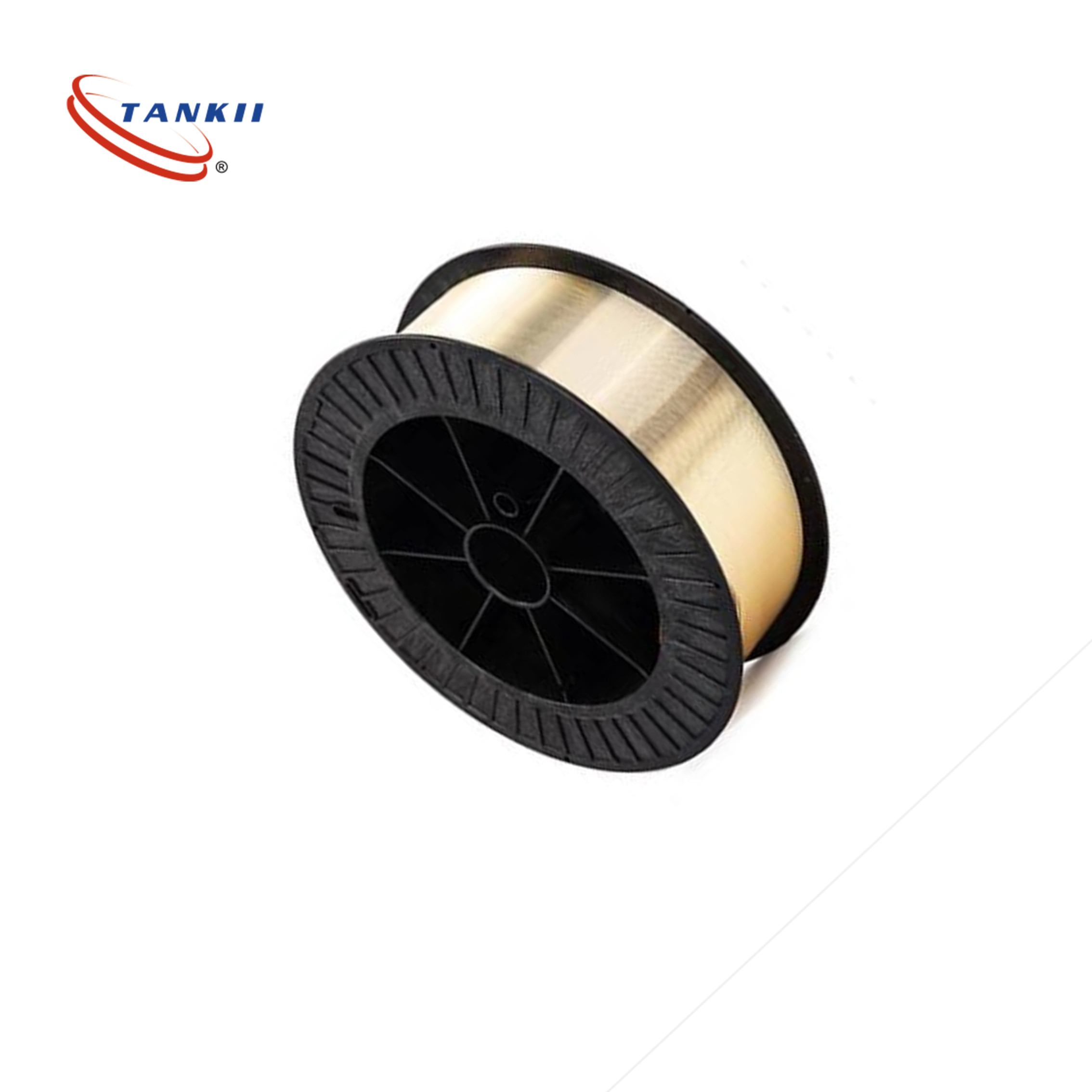

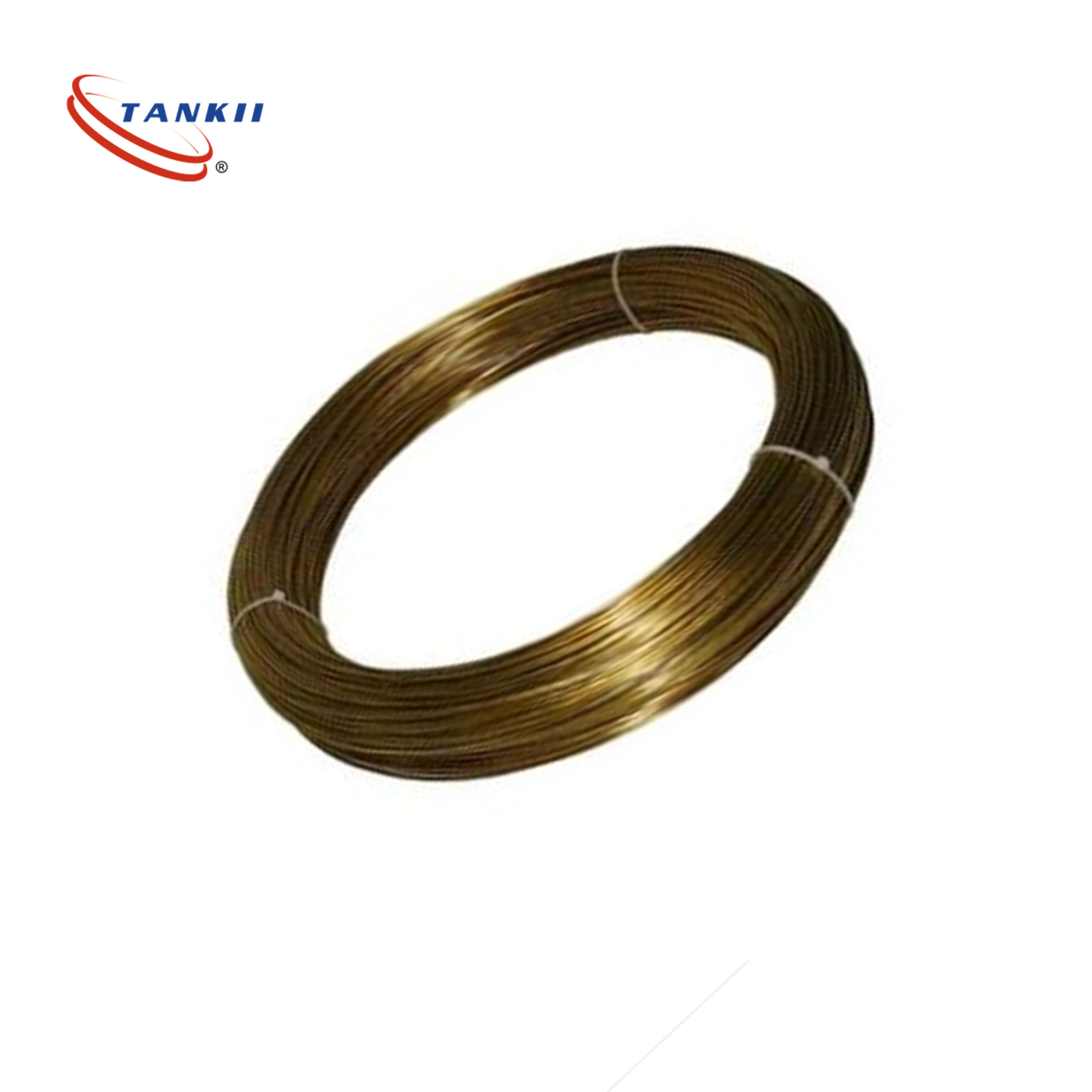

Make up:

Diameter:0.80 – 1.00 – 1.20 – 1.60 -2.40

Spools:D100,D200,D300,K300,KS300,BS300

Rods:1.20 – 5.0 mm x 350mm-1000 mm

Electrodes available.

Further make ups on request.

Product detail pictures:

Related Product Guide:

Persisting in "High quality, Prompt Delivery, Aggressive Price", now we have established long-term cooperation with consumers from equally overseas and domestically and get new and old clients' large comments for OEM Manufacturer Hai-30 - Phosphor Bronze-C/Ercusn-C/Scu5210 Copper Alloys Welding Wire – TANKII , The product will supply to all over the world, such as: Manchester, Namibia, Lithuania, Corporate goal: Customers' satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top