OEM/ODM Factory Air Duct Heating - Ceramic/air Open coil heaters/heating element with NiCr8020 heating wire – TANKII

OEM/ODM Factory Air Duct Heating - Ceramic/air Open coil heaters/heating element with NiCr8020 heating wire – TANKII Detail:

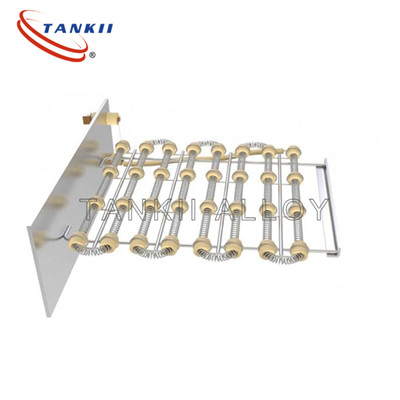

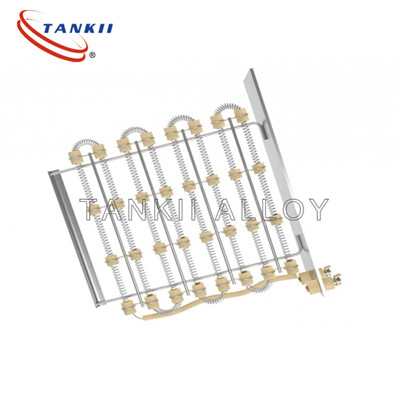

Ceramic/air Open coil heaters/heating element with NiCr8020 heating wire

Open coil heaters are air heaters that expose the maximum heating element surface area directly to an airflow. The choice of alloy, dimensions, and wire gauge are strategically chosen to create a custom solution based on an application’s unique needs. Basic application criteria to consider include temperature, airflow, air pressure, environment, ramp speed, cycling frequency, physical space, available power, and heater life.

Open coil elements are the most efficient type of electric heating element while also the most economically feasible for most heating applications. Used predominantly in the duct heating industry, open coil elements have open circuits that heat air directly from the suspended resistive coils. These industrial heating elements have fast heat up times that improve efficiency and have been designed for low maintenance and easily, inexpensive replacement parts.

TANKII is a leading manufacturer of open coil heaters, specializing in custom-engineered heating solutions to fit exacting requirements. We offer a standard line of open coil heaters that can be modified.

Open coil heating elements from TANKII are typically made for duct process heating, forced air & ovens and for pipe heating applications. Open coil heaters are used in tank and pipe heating and/or metal tubing. A minimum clearance of 1/8’’ is required between the ceramic and the inside wall of the tube. Installing an open coil element will provide excellent and uniform heat distribution over a large surface area.

Open coil heater elements are an indirect industrial heating solution to decrease watt density requirements or the heat fluxes on the surface area of the pipe connected to the heated section and prevent heat sensitive materials from coking or breaking down.

Advantages of Open Coil Heating Elements :

In case you’re looking for a product that suits your simple space heating application, you’d better consider an open coil duct heater, since it provides lower kW output.

available in small size compared to a finned tubular heating element

Releases heat directly into the air stream, which makes it run cooler that the finned tubular element

Has a lower drop in pressure

Provides a large electrical clearance

Using correct heating elements on heating applications can help minimize your manufacturing costs. If you need a reliable partner for your industrial application needs, contact us today. One of our customer support specialists will be waiting to assist you.

The selection of the correct wire gauge, wire type and coil diameter requires quite some experience. There are standard elements available on the market, but quit often they need to be custom built. Open coil air heaters work best below air velocities of 80 FPM. Higher air velocities could cause the coils to touch each other and short out. For higher velocities, select a tubular air heater or strip heater.

The big advantage of open coil heating elements is the very quick response time.

There are standard open coil heating elements available on the market and we carry some in stock. Most of these elements need a constant airflow over the resistance wire, but if the watt densities are low enough they may not burn out in still air.

Applications :

Air Duct heating

Furnace heating

Tank heating

Pipe heating

Metal tubing

Ovens

Product detail pictures:

Related Product Guide:

In order to best meet client's needs, all of our operations are strictly performed in line with our motto "High Quality, Competitive Price, Fast Service" for OEM/ODM Factory Air Duct Heating - Ceramic/air Open coil heaters/heating element with NiCr8020 heating wire – TANKII , The product will supply to all over the world, such as: France, Belize, Spain, We are proud to supply our products to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top