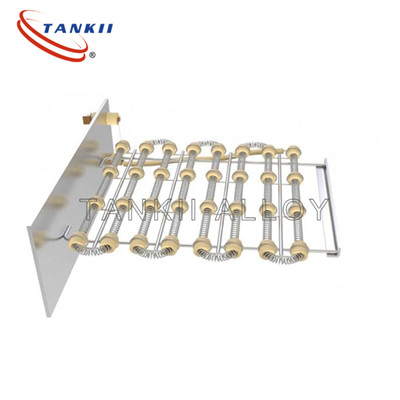

Popular Design for In Cartridge Heaters For Liquid Heating - Copper Nickel Alloy Wire – TANKII

Popular Design for In Cartridge Heaters For Liquid Heating - Copper Nickel Alloy Wire – TANKII Detail:

Product Description

Copper Nickel (CuNi) alloys are medium to low resistance materials typically used in applications with maximum operating temperatures up to 400°C (750°F).

With low temperature coefficients of electrical resistance, resistance, and thus performance, is consistent regardless of temperature. Copper Nickel alloys mechanically boast good ductility, are easily soldered and welded, as well as have outstanding corrosion resistance. These alloys are typically used in high current applications requiring a high level of precision.

Copper-base heat resistance alloy wire resistivity is low, has good corrosion resistance, welding property and machinable property , suitable for in thermal overload relay, a low-voltage circuit breakers, and other low- voltage electrical appliances and household appliances and other electrical appliances manufacturing heating element, and is an important material in production of heating cable.

| Code | Resistivity | Ma.Working Temper | Temp.Coeffi. Of Resistance | EMF Against Copper (0~100℃) | Chemical Composition (%) | Mechanical,Properties | |||||

| Mn | Ni | Cu | Tensile Strength (N/mm2) | Elongation % (Less than) | |||||||

| Diameter<=1.0mm | Diameter>=1.0mm | ||||||||||

| NC003 | CuNi1 | 0.03 | 200 | <100 | -8 | - | 1 | Rest | 210 | 18 | 25 |

| NC005 | CuNi2 | 0.05 | 200 | <120 | -12 | - | 2 | Rest | 220 | 18 | 25 |

| NC010 | CuNi6 | 0.10 | 220 | <60 | -18 | - | 6 | Rest | 250 | 18 | 25 |

| NC012 | CuNi8 | 0.12 | 250 | <57 | -22 | - | 8 | Rest | 270 | 18 | 25 |

| NC015 | CuNi10 | 0.15 | 250 | <50 | -25 | - | 10 | Rest | 290 | 20 | 25 |

| NC020 | CuNi14 | 0.20 | 250 | <38 | -28 | 0.3 | 14.2 | Rest | 310 | 20 | 25 |

| NC025 | CuNi19 | 0.25 | 300 | <25 | -32 | 0.5 | 19 | Rest | 340 | 20 | 25 |

| NC030 | CuNi23 | 0.30 | 300 | <16 | -34 | 0.5 | 23 | Rest | 350 | 20 | 25 |

| NC035 | CuNi30 | 0.35 | 300 | <10 | -37 | 1.0 | 30 | Rest | 400 | 20 | 25 |

| NC040 | CuNi34 | 0.40 | 350 | 0 | -39 | 1.0 | 34 | Rest | 400 | 20 | 25 |

| NC050 | CuNi44 | 0.50 | 400 | <-6 | -43 | 1.0 | 34 | Rest | 420 | 20 | 25 |

| Alloy | DN-Trade Name | Material-No. | UNS-No. | ASTM Specification | DIN Specification |

| CuNi1 | CuNi1 | ||||

| CuNi2 | CuNi2 | 2.0802 | C70200 | ASTM B267 | DIN 17471 |

| CuNi6 | CuNi6 | 2.0807 | C70500 | ASTM B267 | DIN 17471 |

| CuNi10 | CuNi10 | 2.0811 | C70700 | ASTM B267 | DIN 17471 |

| CuNi10Fe1Mn | CuNi10Fe1Mn | (2.0872) / (CW352H) | C70600 | ASTM B151 | |

| CuNi15 | CuNi15 | ||||

| CuNi23Mn | CuNi23Mn | 2.0881 | C71100 | ASTM B267 | DIN 17471 |

| CuNi30Mn | CuNi30Mn | 2.0890 | |||

| CuNi30Mn1Fe | CuNi30Mn1Fe | (2.0882) / (CW354H) | C71500 | ASTM B151 | |

| CuNi44Mn1 | Vernicon | 2.0842 | DIN 17471 |

294:Common Name:

Alloy294, Cuprothal294, Nico, MWS-294, Cupron, Copel, Alloy45, Cu-Ni102, Cu-Ni44, Cuprothal, Cupron, Copel, Neutrology, Advance, Konstantan

A30:Common Name:

Alloy 30, MWS-30, Cuprothal 5, Cu-Ni 23, Alloy 260, Cuprothal 30 HAI-30, Cu-Ni2, Alloy 230, Nickel Alloy 30

A90: Common Name:

Alloy 95, 90 Alloy, MWS-90, Cu-Ni 10, Cuprothal 15, Cu-Ni 10, Alloy 320 Alloy 90, Alloy 290, #95 Alloy, Cuprothal 90,HAI-90,Alloy 260,Nickel Alloy 90

A180: Common Name:

Alloy 180, 180 Alloy, MWS-180, Cuprothal 30, Midohm, Cu-Ni 23, Nickel Alloy 180

Product detail pictures:

Related Product Guide:

Using a complete scientific top quality management program, great high-quality and fantastic religion, we win great track record and occupied this area for Popular Design for In Cartridge Heaters For Liquid Heating - Copper Nickel Alloy Wire – TANKII , The product will supply to all over the world, such as: India, Morocco, Peru, Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us. Thank you - Your support continuously inspires us.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top