Professional China Alloy Heating Wires - Cr15Al5 FeCrAl Heating Resistance Alloy Wire for Furnace Heating – TANKII

Professional China Alloy Heating Wires - Cr15Al5 FeCrAl Heating Resistance Alloy Wire for Furnace Heating – TANKII Detail:

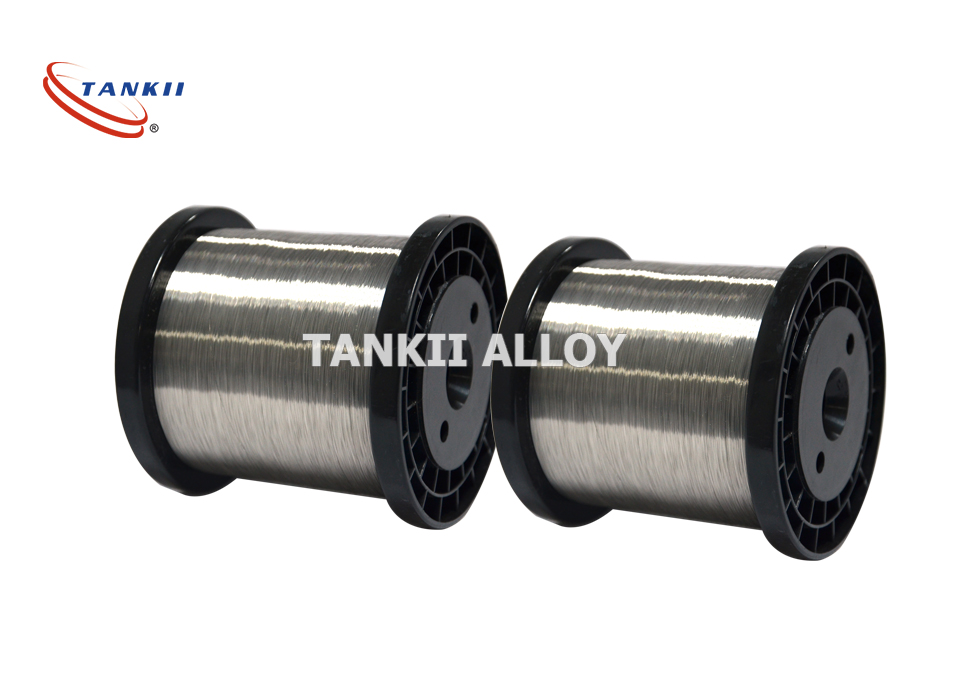

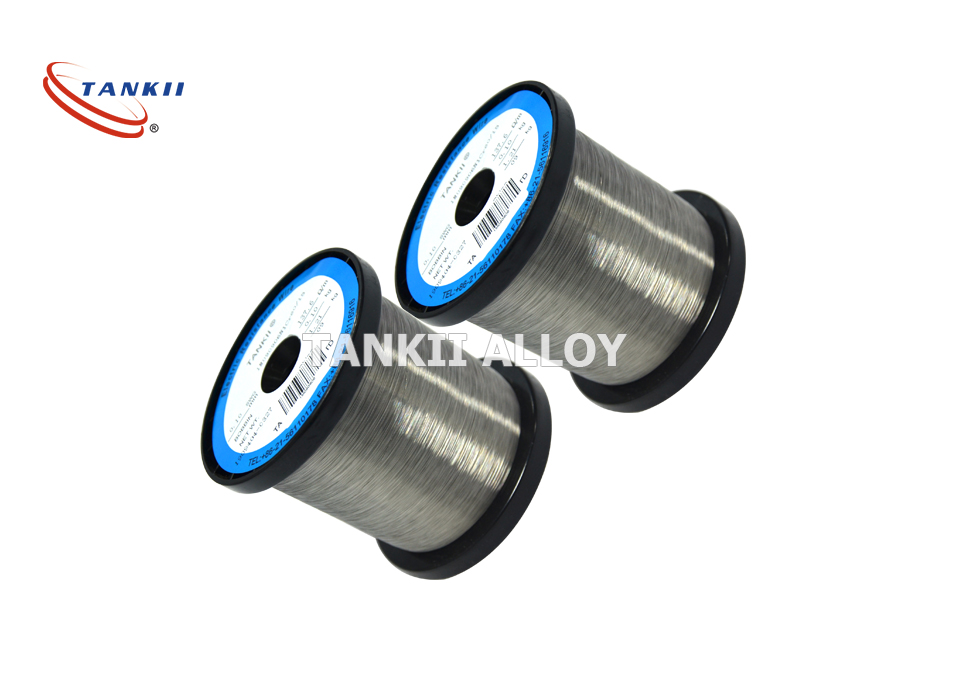

Resistance Wire:

1)Iron Chrome Aluminum Wire

CrAl 14-4, CrAl 15-5, CrAl 20-5, CrAl 25-5, etc.

2)Nichrome Wire

NiCr 80/20, NiCr 70/30, NiCr 60/15, NiCr 35/20

3)Nickel Copper Alloy Wire

Alloy 30, Alloy 60, Alloy 90, Constantan Wire

For more details, pls visit our website or email us.

SPECIFICATIONS:

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

Relevance:

Fecrak us an ideal alloy with an excessive specific real resistance(1.20-1.30 ohm-mm2/m)which combine a heat resistance up to 1450C and is claimed to be indispensable at temperature extremes.These properties allow using this alloy extensively while manufacturing heating units. It has a perfect corrosive resistance on air,in argon, in a vacuum, oxidizing, sulfur-containing and carboniferous environments.It shows not very high relative density(7.2g/cm3),but it has a great yield limit.

Cr15Al5 Eurofechral

| material | grade | UNS name | DIN | Density | ASTM |

| fecral | 1.4725 | K 92500 | 17470 | 7.4 | B 603-1 |

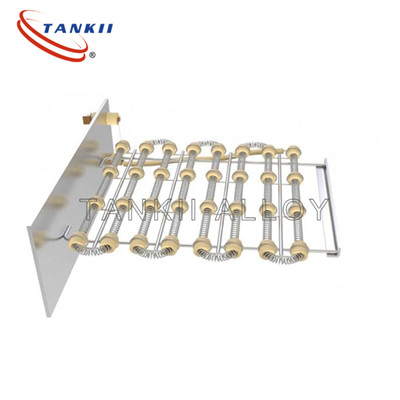

The main applications:kilns,resistor elements,high-temperature furnaces,industrial tubular heating elements and heaters.

Percentage Composition:

| Al | Cr | Fe | Mn | C | Si | Ni | Cu | Ti | Other | Rare earth elements |

| 4.6-5.8 | 14.5-15.5 | Basis | Max0.7 | till 0.05 | till 0.6 | till 0.6 | … | till 0.6 | Zr≤0.3 | … |

Mechanical Characteristics T°20°C

| Number of bowings | Percentage Extension |

| >5 times | >16% |

Phyiscal Characteristics T°20°C

| Hardness | Density | Breaking load | Maximum Working temperature 850C | Electrical resistivity | Magnetism | Melting points (°C) |

| 200-260 HB | 7.1g/cm3 | 637-784m/pa | 1.30 ohn-mm2/m | Magnetic | 1400 °C |

Product detail pictures:

Related Product Guide:

The corporation keeps to the operation concept "scientific management, superior quality and performance primacy, consumer supreme for Professional China Alloy Heating Wires - Cr15Al5 FeCrAl Heating Resistance Alloy Wire for Furnace Heating – TANKII , The product will supply to all over the world, such as: Accra, Madras, Portugal, We have gained a lot of recognition among customers spread all across the world. They trust us and always give repetitive orders. Furthermore, mentioned below are some of the major factors that have played significant role in our tremendous growth in this domain.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.