Welcome to our websites!

Tankii 0.8mm CuMn8Ni Manganin Wire Wear Resistant Electrical Conductive Wire

Product Description

CuMn8Ni Manganin Wire (0.8mm Diameter)

Product Overview

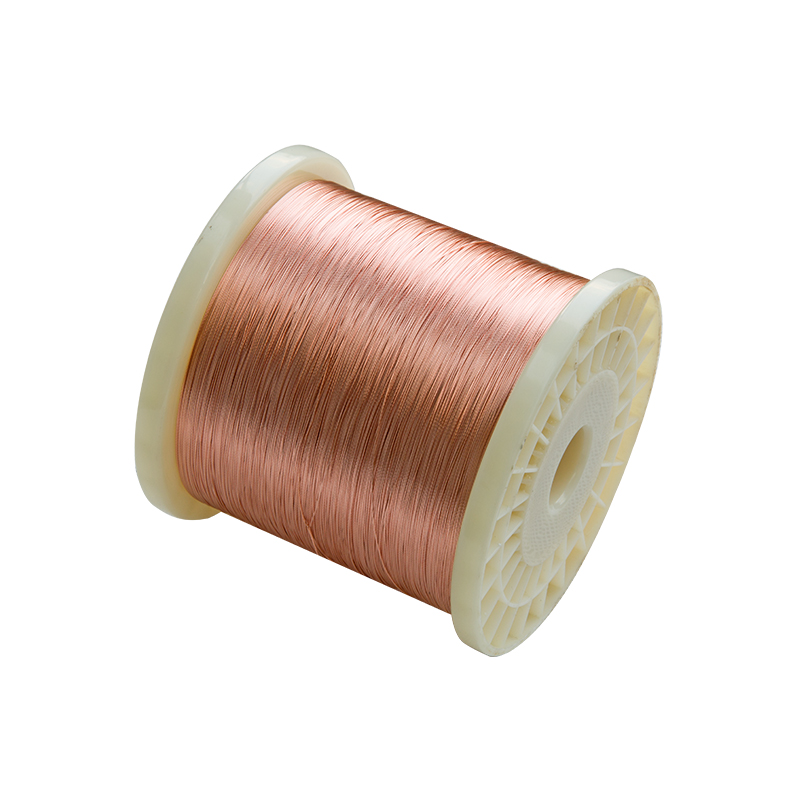

CuMn8Ni manganin wire (0.8mm diameter) from Tankii Alloy Material is a high-precision copper-manganese-nickel alloy wire with a bright, uniform surface finish as shown. Composed of Cu (balance) + 7.0–9.0% Mn + 1.0–2.0% Ni with trace stabilizing elements, it is produced via vacuum smelting, hot rolling, multi-pass precision drawing, and controlled annealing. It features ultra-low temperature coefficient of resistance (TCR), stable resistivity, and excellent mechanical ductility, making it ideal for precision wirewound resistors, current shunts, strain gauges, and high-frequency signal components requiring long-term stability and reliable performance.

Standard Designations & Core Material Foundation

- Alloy Grade: CuMn8Ni

- International Equivalents:

- UNS: C18500

- DIN: 2.0870

- JIS: C1850

- GB/T: 3131-2019 (Mn8Ni)

- Key Specification: 0.8mm diameter (tolerance: ±0.005mm); soft/half-hard/hard temper available

- Chemical Composition (wt%): Mn: 7.0–9.0%; Ni: 1.0–2.0%; Cu: balance; Fe ≤0.3%; Pb ≤0.05%; C ≤0.1%

- Compliant Standards: ASTM B124, EN 13602, GB/T 3131-2019, RoHS 2.0

- Manufacturer: Tankii Alloy Material, certified to ISO 9001 and ISO 14001

Key Core Advantages (Centered on 0.8mm Fine Wire)

1. Ultra-Stable Electrical Performance

- Low TCR & Stable Resistivity: Resistivity = 0.30 μΩ·m (20℃), TCR = ±8×10⁻⁶/℃ (0–100℃), ensuring resistance drift ≤0.008%/℃—critical for precision measurement and control circuits.

- Low Signal Attenuation: 0.8mm diameter balances conductivity and flexibility, minimizing signal loss in high-frequency and precision sensing applications.

2. Excellent Mechanical & Processing Properties

- High Ductility & Flexibility: Tensile strength ≥400 MPa (hard temper) / ≥280 MPa (soft temper), elongation ≥25% (soft temper), supporting tight winding (minimum radius ≥1.6mm) and complex forming without breaking.

- Bright Surface & Good Solderability: Polished bright finish (Ra ≤0.6μm) ensures low contact resistance and reliable soldering, ideal for resistor winding and terminal connections.

3. Good Corrosion & Environmental Resistance

- Atmospheric & Mild Corrosion Resistance: Forms a dense oxide film, passes 500-hour ASTM B117 salt spray test without obvious corrosion.

- Wide Operating Temperature: -40℃ to 130℃, stable performance in industrial, automotive, and electronic equipment environments.

Technical Specifications

| Attribute | Value (Typical) |

|---|---|

| Alloy Grade | CuMn8Ni (soft/half-hard/hard temper) |

| Diameter | 0.8mm (±0.005mm, customizable 0.1–3.0mm) |

| Resistivity (20℃) | 0.30 μΩ·m |

| TCR (0–100℃) | ±8×10⁻⁶/℃ |

| Tensile Strength | ≥400 MPa (hard); ≥280 MPa (soft) |

| Elongation | ≥25% (soft temper) |

| Hardness (HV) | 110–140 (hard); 75–95 (soft) |

| Density | 8.88 g/cm³ |

| Surface Finish | Bright polished (Ra ≤0.6μm) |

| Operating Temperature | -40℃ to 130℃ |

Product Specifications

| Item | Specification |

|---|---|

| Supply Form | Spools (1kg/5kg/10kg per spool) |

| Temper | Soft (annealed), Half-Hard, Hard (as-drawn) |

| Surface Treatment | Bright polished, pickled, or tinned (optional) |

| Processability | Winding, bending, soldering, laser welding |

| Packaging | Plastic spool + PE film + carton (anti-oxidation & damage) |

| Customization | Diameter (0.1–3.0mm); length; temper; surface treatment |

Typical Application Scenarios

- Precision Resistors: Wirewound precision resistors, potentiometers, and Wheatstone bridges for multimeters & power analyzers.

- Current Shunts: Medium-current shunts for battery management systems (BMS), power meters, and automotive electronics.

- Strain Gauges & Sensors: Core material for mechanical stress testing and temperature compensation sensors.

- High-Frequency Electronics: Signal conditioning modules, RF circuits, and precision impedance components.

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top