Welcome to our websites!

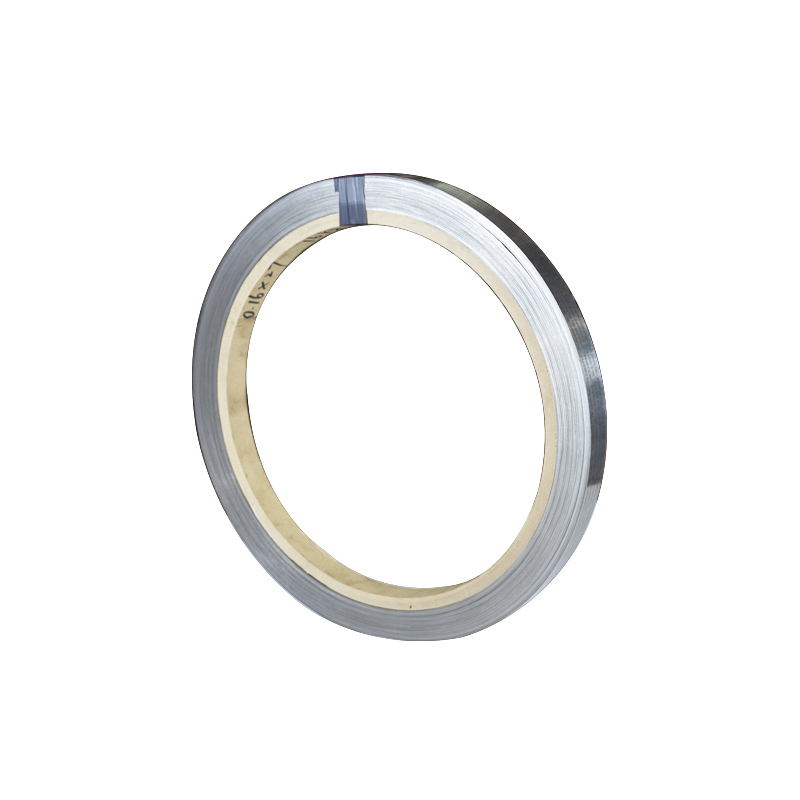

Tankii Hot Sale TM-1/FPA223-80/5J1480 Bimetallic Strip 0.1mm Thickness × 100mm Width

Product Description

TM-1 Bimetallic Strip (0.1mm Thickness × 100mm Width)

Product Overview

TM-1 bimetallic strip (0.1mm×100mm), a precision-engineered functional material from Tankii Alloy Material, is a thin-gauge composite strip composed of two dissimilar alloys with distinct thermal expansion coefficients—bonded via our proprietary hot-rolling diffusion technology. Optimized for ultra-thin applications requiring both miniaturization and reliable thermal actuation, this strip combines a fixed 0.1mm thickness (ideal for compact devices) with a 100mm standard width (suited for large-area temperature sensing or batch processing). Leveraging Huona’s expertise in thin-gauge composite manufacturing, the TM-1 grade delivers exceptional thermal sensitivity, uniform deformation, and strong interfacial bonding—making it a core component for micro-thermostats, precision temperature compensators, and miniaturized overheat protection devices.

Standard Designations & Core Composition

- Product Grade: TM-1 (specialized bimetallic grade, tailored for ultra-thin gauge thermal responsiveness)

- Dimensional Specification: 0.1mm thickness (tolerance: ±0.003mm) × 100mm width (tolerance: ±0.15mm)

- Composite Structure: Typically features a high-expansion layer (e.g., Cu-Mn-Zn alloy, α≈20×10⁻⁶/℃) and a low-expansion layer (e.g., Fe-Ni 36 alloy, α≈1.6×10⁻⁶/℃), with interfacial shear strength ≥145 MPa (tested per GB/T 14985)

- Compliant Standards: Adheres to GB/T 14985-2017 (Chinese standard for bimetallic strips) and IEC 60694 for thermal control components

- Manufacturer: Tankii Alloy Material, certified to ISO 9001 and ISO 14001, with in-house thin-gauge rolling and precision slitting capabilities

Key Advantages (vs. Standard & Thick-Gauge Bimetallic Strips)

The TM-1 strip (0.1mm×100mm) stands out for its ultra-thin design and large-width suitability:

- Ultra-Thin Precision: 0.1mm thickness (30% thinner than common 0.15mm strips) enables integration into micro-devices (e.g., wearable sensors, miniaturized circuit breakers) while maintaining strict thickness uniformity (±0.003mm) to avoid uneven thermal deformation.

- Enhanced Thermal Sensitivity: High expansion coefficient ratio (~12.5:1) delivers a temperature-induced curvature of 12-15 m⁻¹ (at 100℃ vs. 25℃)—20% higher than thick-gauge strips (0.3mm+), ensuring fast actuation in low-power devices.

- Large Width for Batch Processing: 100mm standard width matches industrial stamping panel sizes, allowing simultaneous production of 50+ micro-components (e.g., thermostat contacts) per strip—reducing processing time by 40% vs. narrow-width strips.

- Strong Interfacial Bonding: Proprietary diffusion bonding technology eliminates delamination even after 8,000 thermal cycles (-40℃ to 180℃)—solving the common issue of thin-gauge bimetallics (≤0.1mm) being prone to layer separation.

- Excellent Machinability: Ultra-thin gauge enables laser cutting into intricate micro-shapes (minimum feature size: 0.5mm) and tight bending (radius ≥1× thickness) without cracking—critical for automated assembly of compact devices.

Technical Specifications

| Attribute | Value (Typical) |

|---|---|

| Thickness | 0.1mm (tolerance: ±0.003mm) |

| Width | 100mm (tolerance: ±0.15mm) |

| Length per Roll | 50m – 200m (cut-to-length available: ≥50mm) |

| Thermal Expansion Coefficient Ratio (High/Low Layer) | ~12.5:1 |

| Operating Temperature Range | -40℃ to 180℃ (continuous); Short-term: up to 220℃ (≤30 minutes) |

| Actuation Temperature Deviation | ±2℃ (at rated points: 50℃ – 150℃) |

| Interfacial Shear Strength | ≥145 MPa |

| Tensile Strength (Transverse) | ≥470 MPa |

| Elongation (25℃) | ≥10% |

| Resistivity (25℃) | 0.17 – 0.30 Ω·mm²/m |

| Surface Roughness (Ra) | ≤0.6μm (mill finish) |

Product Specifications

| Item | Specification |

|---|---|

| Surface Finish | Mill finish (oxide-free) or passivated (optional, for 72-hour salt spray resistance) |

| Flatness | ≤0.06mm/m (critical for uniform stamping and thermal deformation) |

| Bonding Quality | 100% interfacial bonding (no voids >0.03mm², verified via X-ray inspection) |

| Solderability | Optional tin-plating (2-3μ thickness) for enhanced solderability in micro-connections |

| Packaging | Vacuum-sealed in anti-oxidation bags with desiccants; plastic spools (120mm diameter) to prevent strip warping |

| Customization | Adjustment of actuation temperature (40℃ – 180℃), width trimming (minimum 10mm), and pre-stamped micro-patterns |

Typical Applications

- Micro-Thermostats: Temperature control in wearable devices (e.g., smart watches), medical insulin coolers, and miniaturized HVAC systems (0.1mm thickness fits slim designs).

- Precision Overheat Protection: Circuit breakers for lithium-ion batteries (e.g., drone batteries, wireless earbuds) and micro-motors (fast actuation prevents thermal runaway).

- Large-Area Sensing: Thermal profiling strips for PCB boards (100mm width covers multiple components) and flexible electronics (uniform temperature response across the strip).

- Consumer Electronics: Thermal actuators for laptop heat sinks, printer fuser controls, and smartphone battery protection modules.

- Industrial Micro-Devices: Temperature-compensating shims for MEMS sensors (e.g., pressure sensors in autonomous vehicles) and tiny thermal switches for IoT devices.

Tankii Alloy Material subjects every batch of TM-1 strips (0.1mm×100mm) to rigorous testing: interfacial shear strength verification, 1000-cycle thermal stability tests, and laser-based dimensional inspection. Free samples (100mm×50mm) and thermal curvature vs. temperature curves are available upon request. Our technical team provides tailored support—including alloy layer optimization for specific actuation temperatures and micro-stamping process guidelines—to ensure the strip meets the demands of compact, high-precision applications.

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top