Welcome to our websites!

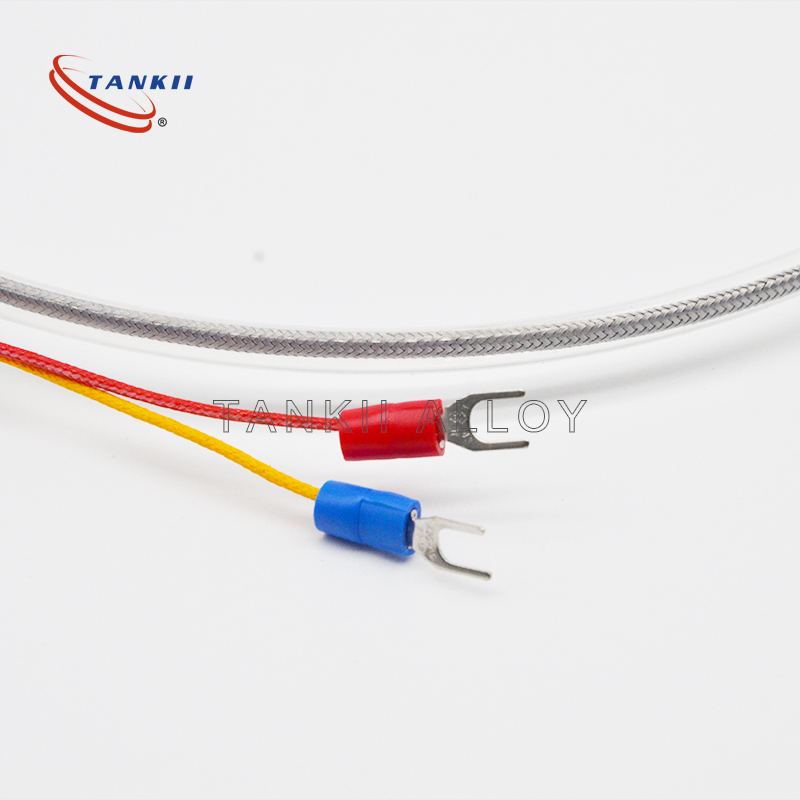

Tankii J-Type Thermocouple Bare Wire SWG30/SWG25/SWG19 High Thermal Sensitivity

Product Description

Type J Thermocouple Bare Wire (SWG30/SWG25/SWG19)

Product Overview

Type J thermocouple bare wire, a high-precision temperature-sensing element crafted by Tankii Alloy Material, consists of two dissimilar alloy conductors—iron (positive leg) and constantan (copper-nickel alloy, negative leg)—engineered for accurate temperature measurement in moderate-temperature environments. Available in three standard wire gauges: SWG30 (0.305mm), SWG25 (0.51mm), and SWG19 (1.02mm), this bare wire eliminates insulation interference, making it ideal for custom thermocouple assembly, high-temperature calibration, and applications requiring direct contact with measured media. Leveraging Huona’s advanced alloy smelting and drawing technologies, each gauge maintains strict dimensional tolerance and stable thermoelectric properties, ensuring consistency across batches.

Standard Designations

- Thermocouple Type: J (Iron-Constantan)

- Wire Gauges: SWG30 (0.315mm), SWG25 (0.56mm), SWG19 (1.024mm)

- International Standards: Complies with IEC 60584-1, ASTM E230, and GB/T 4990

- Form: Bare wire (uninsulated, for custom insulation/protection)

- Manufacturer: Tankii Alloy Material, certified to ISO 9001 and calibrated to national temperature standards

Key Advantages (vs. Insulated J-Type Wires & Other Thermocouple Types)

This bare wire solution stands out for its versatility, accuracy, and gauge-specific adaptability:

- Gauge-Tailored Performance: SWG30 (thin gauge) offers high flexibility for tight-space installations (e.g., small sensors); SWG19 (thick gauge) provides enhanced mechanical strength for industrial environments; SWG25 balances flexibility and durability for general-purpose use.

- Superior Thermoelectric Accuracy: Generates a stable electromotive force (EMF) with a sensitivity of ~52 μV/°C (at 200°C), outperforming Type K in the 0-500°C range, with Class 1 accuracy (tolerance: ±1.5°C or ±0.25% of reading, whichever is larger).

- Bare Wire Versatility: No pre-applied insulation allows users to customize protection (e.g., ceramic tubes, fiberglass sleeving) based on specific temperature/corrosion requirements, reducing waste from mismatched pre-insulated wires.

- Cost-Effective: Iron-constantan alloy is more affordable than precious metal thermocouples (Types R/S/B) while delivering higher sensitivity than Type K, making it ideal for mid-range temperature measurement (0-750°C) without overspending.

- Good Oxidation Resistance: Performs reliably in oxidizing environments up to 750°C; iron conductor forms a protective oxide layer that minimizes drift, extending service life vs. unalloyed iron wires.

Technical Specifications

| Attribute | SWG30 (0.315mm) | SWG25 (0.56mm) | SWG19 (1.024mm) |

|---|---|---|---|

| Conductor Material | Positive: Iron; Negative: Constantan (Cu-Ni 40%) | Positive: Iron; Negative: Constantan (Cu-Ni 40%) | Positive: Iron; Negative: Constantan (Cu-Ni 40%) |

| Nominal Diameter | 0.305mm | 0.51mm | 1.02mm |

| Diameter Tolerance | ±0.01mm | ±0.015mm | ±0.02mm |

| Temperature Range | Continuous: 0-700°C; Short-term: 750°C | Continuous: 0-750°C; Short-term: 800°C | Continuous: 0-750°C; Short-term: 800°C |

| EMF at 100°C (vs 0°C) | 5.268 mV | 5.268 mV | 5.268 mV |

| EMF at 750°C (vs 0°C) | 42.919 mV | 42.919 mV | 42.919 mV |

| Conductor Resistance (20°C) | ≤160 Ω/km | ≤50 Ω/km | ≤15 Ω/km |

| Tensile Strength (20°C) | ≥380 MPa | ≥400 MPa | ≥420 MPa |

| Elongation (20°C) | ≥20% | ≥22% | ≥25% |

Product Specifications

| Item | Specification |

|---|---|

| Surface Finish | Bright annealed (oxide-free, Ra ≤0.2μm) |

| Supply Form | Spools (length: 50m/100m/300m per gauge) |

| Chemical Purity | Iron: ≥99.5%; Constantan: Cu 59-61%, Ni 39-41%, impurities ≤0.5% |

| Calibration | Traceable to NIST/China National Institute of Metrology (CNIM) |

| Packaging | Vacuum-sealed in argon-filled bags (to prevent oxidation); plastic spools in moisture-proof cartons |

| Customization | Cut-to-length (minimum 1m), special alloy purity (high-purity iron for calibration), or pre-tinned ends |

Typical Applications

- Custom Thermocouple Assembly: Used by sensor manufacturers to fabricate probes with application-specific protection (e.g., ceramic-sheathed probes for furnaces, stainless steel-sheathed probes for liquids).

- Industrial Temperature Sensing: Direct measurement in food processing (oven baking, 100-300°C) and plastic molding (melt temperature, 200-400°C)—SWG25 is preferred for balance of flexibility and strength.

- Calibration Equipment: Reference elements in temperature calibrators (SWG30 for compact calibration cells).

- Automotive Testing: Monitoring engine block and exhaust system temperatures (SWG19 for vibration resistance).

- Laboratory Research: Thermal profiling in material science experiments (0-700°C) where custom insulation is required.

Tankii Alloy Material subjects every batch of Type J bare wire to rigorous quality testing: thermoelectric stability tests (100 cycles of 0-750°C), dimensional inspection (laser micrometry), and chemical composition analysis (XRF). Free samples (1m per gauge) and calibration certificates are available upon request. Our technical team provides tailored guidance—including gauge selection for specific applications and soldering/ welding best practices—to ensure optimal performance in custom thermocouple setups.

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top