Welcome to our websites!

Tankii S-Type Thermocouple Sensor High-Temperature Industrial Measurement And Precision Sensing

Product Description

S-Type Thermocouple Sensor (0-1300℃, 250mm Length)

Product Overview

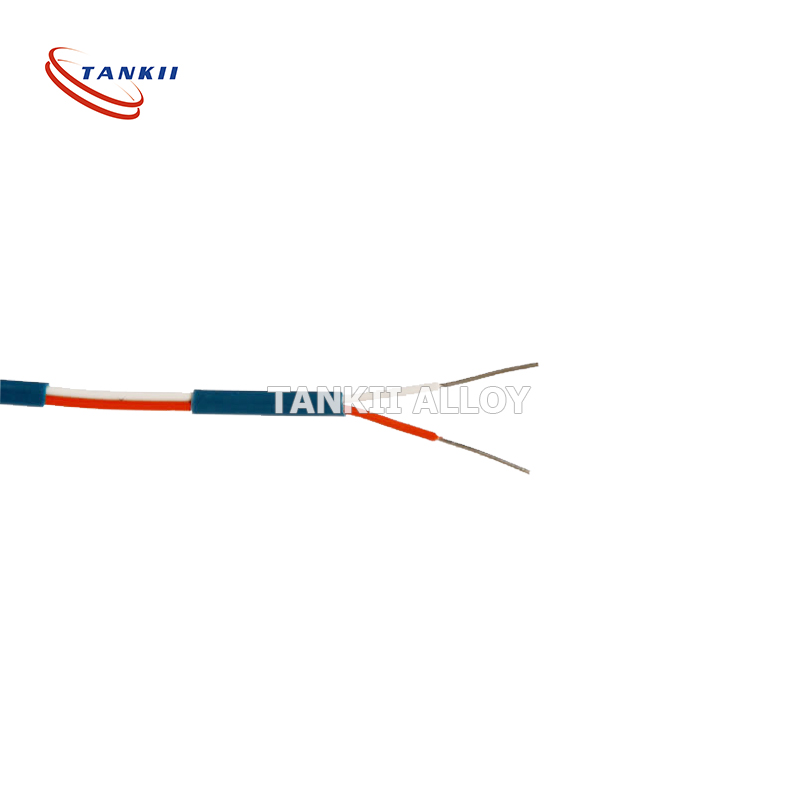

The S-type thermocouple sensor (platinum-rhodium 10%-platinum, Pt10Rh/Pt) from Tankii Alloy Material is a high-precision high-temperature measuring component engineered for extreme thermal environments. With a tailored design of 250mm total length, 7-8mm outer diameter ceramic protection tube, and 0.2mm diameter conductor wire, this sensor achieves accurate temperature detection across 0-1300℃ via the Seebeck effect of noble metal alloys. It integrates excellent high-temperature stability, low measurement drift, and robust structural durability—making it the preferred choice for high-temperature processes such as industrial furnace temperature monitoring, heat treatment thermal profiling, and electronic component high-temperature reliability testing.

Standard Designations & Structural Foundation

- Sensor Grade: S-type (IEC 60584-1 Class 1; equivalent to ANSI/ASTM E230 Type S) – noble metal thermocouple with Pt10Rh (positive electrode) and pure Pt (negative electrode) conductors

- Core Specifications: Temperature range 0-1300℃ (short-term use up to 1400℃ for ≤30min); total length 250mm (measuring end length 50mm, lead wire length 200mm); ceramic protection tube outer diameter 7-8mm (wall thickness 1.2-1.5mm); conductor wire diameter 0.2mm (tolerance ±0.01mm)

- Compliant Standards: IEC 60584-1 (thermocouple accuracy class), GB/T 1672-1997 (platinum-rhodium thermocouples), ASTM E230-19 (standard for noble metal thermocouples)

- Manufacturer: Tankii Alloy Material, certified to ISO 9001 and ISO 14001, with in-house noble metal alloy smelting and sensor calibration capabilities

Key Core Advantages (Tailored for 0-1300℃ & Structural Specifications)

1. High-Temperature Measurement Precision & Stability

Adopts 99.99% high-purity Pt10Rh/Pt conductor wire (0.2mm diameter) with uniform alloy composition—measurement accuracy reaches Class 1 (error ≤±1.5℃ at 0-600℃, ≤±0.25% t at 600-1300℃, t=measured temperature). After 1000 hours of continuous operation at 1200℃, the thermoelectric potential drift is <3μV (equivalent to temperature error <0.4℃)—far superior to K-type thermocouples (drift >10μV at 800℃) and suitable for long-term high-temperature monitoring.

2. Optimized Structural Durability

- Ceramic Protection Tube: 7-8mm outer diameter high-alumina ceramic (Al₂O₃ content ≥95%) with high-temperature resistance up to 1600℃, compressive strength ≥150MPa—effectively isolating molten metal, furnace dust, and corrosive gases while ensuring heat transfer efficiency (thermal conductivity ≥20 W/(m·K) at 800℃).

- Conductor & Connection Design: 0.2mm diameter conductor balances flexibility and high-temperature strength (tensile strength ≥350MPa at 25℃, ≥150MPa at 1300℃); the measuring end adopts spot welding (weld spot diameter 0.3-0.4mm) to ensure stable thermoelectric potential output without contact resistance.

- Total Length Matching: 250mm total length (50mm measuring end + 200mm lead wire) is optimized for industrial furnace side-wall installation—avoids excessive lead wire bending while ensuring the measuring end reaches the core temperature zone.

3. Application-Adapted Reliability

The sensor has good oxidation resistance (forms dense PtO₂ protective film at high temperature) and thermal shock resistance (can withstand 500℃/min temperature change without ceramic tube cracking). The lead wire adopts high-temperature Teflon insulation (operating temperature -60℃ to 260℃) to prevent short circuits in high-temperature workshops, and the terminal is equipped with a standard M12 connector for quick connection to temperature transmitters.

Technical Specifications

|

Attribute

|

Value (Typical)

|

Application Significance

|

|---|---|---|

|

Sensor Type

|

S-type (Pt10Rh/Pt)

|

High-purity noble metal ensures high-temperature stability

|

|

Temperature Range

|

0-1300℃ (continuous); 0-1400℃ (short-term ≤30min)

|

Covers most industrial high-temperature processes

|

|

Measurement Accuracy

|

Class 1: ±1.5℃ (0-600℃); ±0.25% t (600-1300℃)

|

Meets precision heat treatment (e.g., automotive parts quenching) requirements

|

|

Total Length

|

250mm (Customized)

|

Optimized for furnace side-wall installation

|

|

Ceramic Tube Specification

|

Outer diameter 7-8mm

|

Balances protection and heat transfer efficiency

|

|

Conductor Wire Diameter

|

0.2mm (tolerance ±0.01mm)

|

Ensures thermoelectric potential stability and flexibility

|

|

Thermoelectric Potential (1000℃)

|

10.591mV (vs 0℃ reference junction)

|

Complies with IEC 60584-1 standard calibration values

|

|

Response Time (τ₅₀)

|

≤2s (in air at 800℃)

|

Adapts to dynamic temperature changes in heat treatment

|

|

Service Life (1200℃ continuous)

|

≥1000 hours

|

Reduces maintenance frequency for industrial furnaces

|

Product Specifications

|

Item

|

Specification

|

Performance Advantage

|

|---|---|---|

|

Protection Tube Material

|

95% high-alumina ceramic

|

High-temperature resistance & corrosion resistance

|

|

Conductor Insulation

|

High-purity alumina ceramic bead (250℃ section); Teflon (room temperature section)

|

Prevents short circuit at high temperature

|

|

Terminal Connector

|

M12 waterproof connector (IP65 protection level)

|

Quick installation & dustproof/waterproof

|

|

Calibration Certificate

|

NIST-traceable calibration report (optional)

|

Meets metrology verification requirements

|

|

Packaging

|

Shockproof foam + cardboard box; single-piece packaging

|

Prevents ceramic tube breakage during transportation

|

|

Customization

|

Total length (100-1000mm); ceramic tube material (99% alumina for 1600℃); connector type (miniature connector for electronic devices)

|

Adapts to special installation & application needs

|

Typical Application Scenarios

1. Industrial High-Temperature Processes

Used for temperature monitoring in metal heat treatment furnaces (e.g., stainless steel annealing at 900-1100℃) and ceramic sintering kilns (1200-1300℃)—the 7-8mm ceramic tube resists furnace dust erosion, and Class 1 accuracy ensures consistent product quality.

2. Electronic Component Reliability Testing

Applied in high-temperature aging tests of semiconductor chips and power modules (0-1200℃)—the 0.2mm thin conductor and fast response time (≤2s) accurately capture transient temperature changes during component heating, providing data support for reliability evaluation.

3. Pressure Sensor High-Temperature Calibration

As a temperature reference in pressure sensor high-temperature calibration systems (e.g., calibrating automotive engine pressure sensors at 800-1000℃)—stable thermoelectric potential output ensures calibration accuracy of pressure sensors.

4. Laboratory High-Temperature Research

Used in material science laboratories for high-temperature phase change testing (0-1300℃)—the 250mm length is suitable for bench-top furnaces, and optional NIST calibration meets research data traceability requirements.

Quality Assurance & Technical Support

Tankii Alloy Material implements three-stage quality control for S-type thermocouple sensors:

- Conductor Inspection: XRF alloy composition analysis (ensures Pt10Rh content 9.5-10.5%) and four-point probe resistance testing (verifies purity).

- Assembly Testing: High-temperature calibration in a precision furnace (temperature accuracy ±0.1℃) and thermal shock testing (50 cycles of 25℃-1300℃).

- Final Verification: 24-hour continuous operation test at 1200℃ to confirm drift performance and connector waterproof testing (IP65).

Free samples (with calibration report) and on-site installation guidance are available upon request. Our technical team provides customized solutions such as sensor length optimization for special furnaces and matching guidance with temperature transmitters to ensure optimal measurement performance.

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top