Welcome to our websites!

Type KCA 2*0.71 Fiberglass Insulated Thermocouple Wire for High-Temp Sensing

Product Description

Type KCA 2*0.71 Thermocouple Cable with Fiberglass Insulation

Product Overview

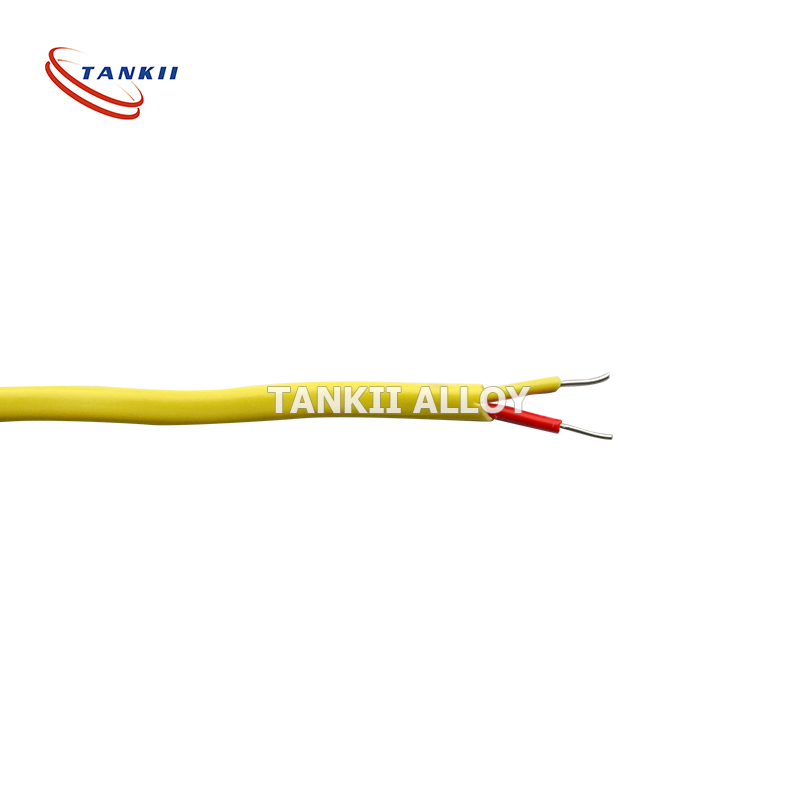

The Type KCA 2*0.71 thermocouple cable, expertly crafted by Tankii, is engineered to meet the demands of precise temperature measurement across a diverse range of industrial applications. Uniquely, its conductors are composed of Iron-Constantan22, with each conductor having a diameter of 0.71mm. This specific alloy combination, paired with high-quality fiberglass insulation in distinct red and yellow colors, offers a reliable and cost-effective solution for temperature sensing setups.

Standard Designations

- Thermocouple Type: KCA (specifically designed as a compensating cable for Type K thermocouples)

- Conductor Specification: 2*0.71mm, featuring Iron-Constantan22 conductors

- Insulation Standard: Fiberglass insulation adheres to IEC 60751 and ASTM D2307 standards

- Manufacturer: Tankii, operating under strict ISO 9001 quality management system

Key Advantages

- Cost-Effective Precision: The Iron-Constantan22 conductors provide a more budget-friendly option compared to some traditional thermocouple alloys, without sacrificing performance within the standard application temperature range. This makes it an excellent choice for large-scale installations where cost control is crucial.

- High-Temperature Resilience: Thanks to the fiberglass insulation, the cable can operate continuously in temperatures ranging from -60°C to 450°C and withstand short-term exposure up to 550°C. This far exceeds the capabilities of common insulation materials like PVC (usually limited to ≤80°C) and silicone (≤200°C), making it suitable for harsh, high-temperature industrial environments.

- Durability and Longevity: The fiberglass braid offers robust resistance to abrasion, chemical corrosion, and thermal aging. This ensures that the cable maintains its integrity and performance over an extended service life, even when subjected to the rigors of industrial settings.

- Flame-Retardant and Safe: Fiberglass is inherently flame-retardant with low smoke emission properties. This makes the Type KCA 2*0.71 cable a safe choice for applications in high-risk environments where fire safety is a top priority.

- Efficient Signal Transmission: The 0.71mm Iron-Constantan22 conductors are optimized to minimize signal loss, ensuring a stable and accurate thermoelectric output. The red and yellow insulation colors also aid in easy identification and proper connection during installation.

Technical Specifications

| Attribute | Value |

|---|---|

| Conductor Material | Positive: Iron; Negative: Constantan22 (a copper-nickel alloy with specific nickel content for optimal thermoelectric performance) |

| Conductor Diameter | 0.71mm (tolerance: ±0.02mm) |

| Insulation Material | Fiberglass, with red insulation for the positive conductor and yellow for the negative conductor |

| Insulation Thickness | 0.3mm – 0.5mm |

| Overall Cable Diameter | 2.2mm – 2.8mm (including insulation) |

| Temperature Range | Continuous: -60°C to 450°C; Short-term: up to 550°C |

| Resistance at 20°C | ≤35Ω/km (per conductor) |

| Bending Radius | Static: ≥8× cable diameter; Dynamic: ≥12× cable diameter |

Product Specifications

| Item | Specification |

|---|---|

| Cable Structure | 2-core |

| Length per Spool | 100m, 200m, 300m (custom lengths are available upon request from Tankii to meet specific project requirements) |

| Moisture Resistance | Water-resistant |

| Packaging | Shipped on plastic spools and wrapped in moisture-proof material, following Tankii’s standard and reliable packaging practices |

Typical Applications

- Industrial Furnaces and Heat Treatment: Monitoring and controlling temperatures in industrial furnaces used for metal heat treatment processes. The cable’s stability and accuracy help ensure consistent quality of the treated metals.

- Metal Smelting and Casting: Measuring temperatures during metal smelting and casting operations. Precise temperature control is essential in these processes to optimize production and maintain product quality, and the Type KCA 2*0.71 cable delivers the required reliability.

- Ceramic and Glass Manufacturing: Employed in kilns and furnaces for ceramic and glass production, where accurate temperature measurement is crucial for achieving the desired product properties.

- Automotive and Aerospace Engine Testing: Used to monitor engine temperatures during testing phases. The cable’s ability to withstand harsh conditions and provide accurate data contributes to ensuring the optimal performance and reliability of engines.

Tankii is committed to strict quality control for every batch of Thermocouple cables. Each cable undergoes comprehensive thermal stability and insulation resistance testing to guarantee compliance with international standards. Free samples (1m length) are available for customers to evaluate the product, along with detailed technical datasheets. Our experienced technical team is always ready to offer tailored advice based on specific application requirements, leveraging years of expertise in thermocouple cable development.

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top