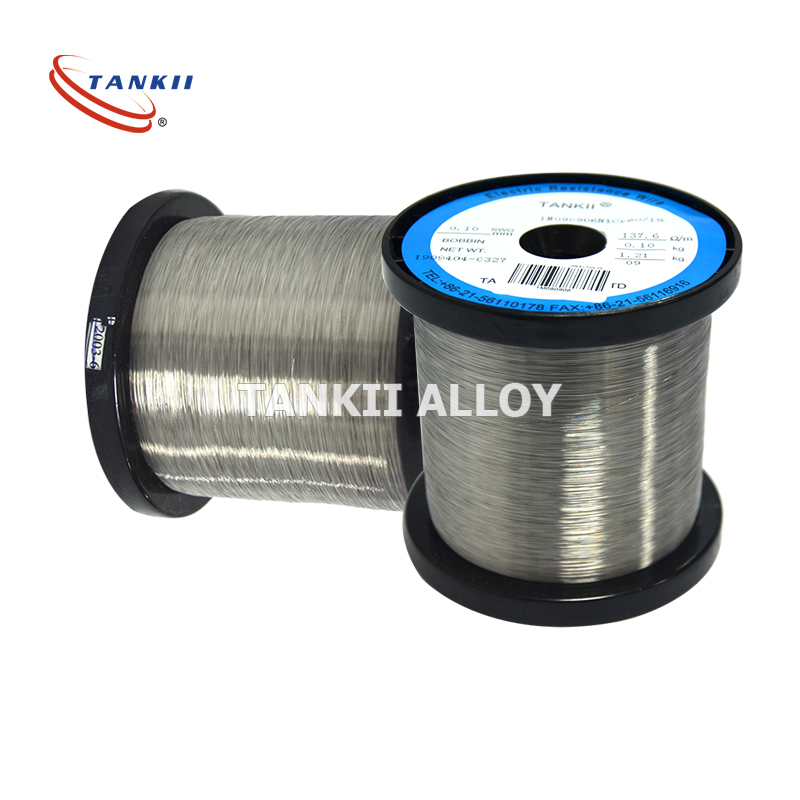

1.6mm 0Cr21Al4 Alloy Electric heating wire FeCrAl Resistance wire

1.6mm 0Cr21Al4 FeCrAl Alloy High Resistance Electric Resistance Heating Wire

Fe-Cr-Al alloy has the characteristic of high resistivity,low temperature resistance coefficient,high operating temperature,good anti-oxidation and anti-corrosion under high temperature.

It is widely used in industrial furnace, household appliances, industry furnace, metallurgy, machinery, aircraft, automotive, military and other industries producing heating elements and resistance elements.

FeCrAl alloy series: OCr15Al5,1Cr13Al4, 0Cr21Al4, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb,0Cr27Al7Mo2, and etc

Size dimension range:

Wire: 0.01-10mm

Ribbons: 0.05*0.2-2.0*6.0mm

Strip: 0.05*5.0-5.0*250mm

Bar:10-50mm

| Alloy Type | Diameter | Resistivity | Tensile | Elongation (%) |

Bending | Max. Continuous |

Working Life |

| (mm) | (μΩm)(20°C) | Strength | Times | Service | (hours) | ||

| (N/mm²) | Temperature (°C) |

||||||

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

3) High quality assured:

Our works has a good command of advanced technological process in the respect of smelting, rolling, drawing and heat treatment up to finished products, together with the chemical analysis department, the physical testing department and the quality control department, we operate an all-round monitoring of our products from raw materials to final products.

4) Usage: Resistance heating elements; Material in metallurgy; Household appliances; Mechanical manufacturing and other industries.

5)We can also supply other products by processing on your order: Stranded wire, twisted wire, coiled wire, wave-shaped wires and different kinds of standard or non-standard electrical heating element.

Shanghai TANKII ALLOY MATERIAL Co., Ltd.