Alloy 294 - China Factory, Suppliers, Manufacturers

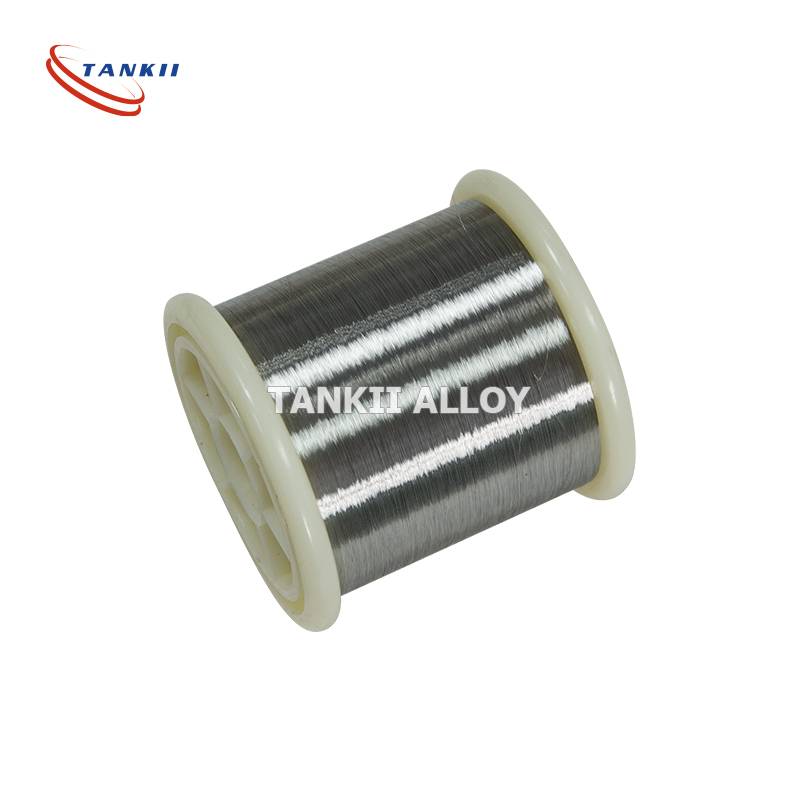

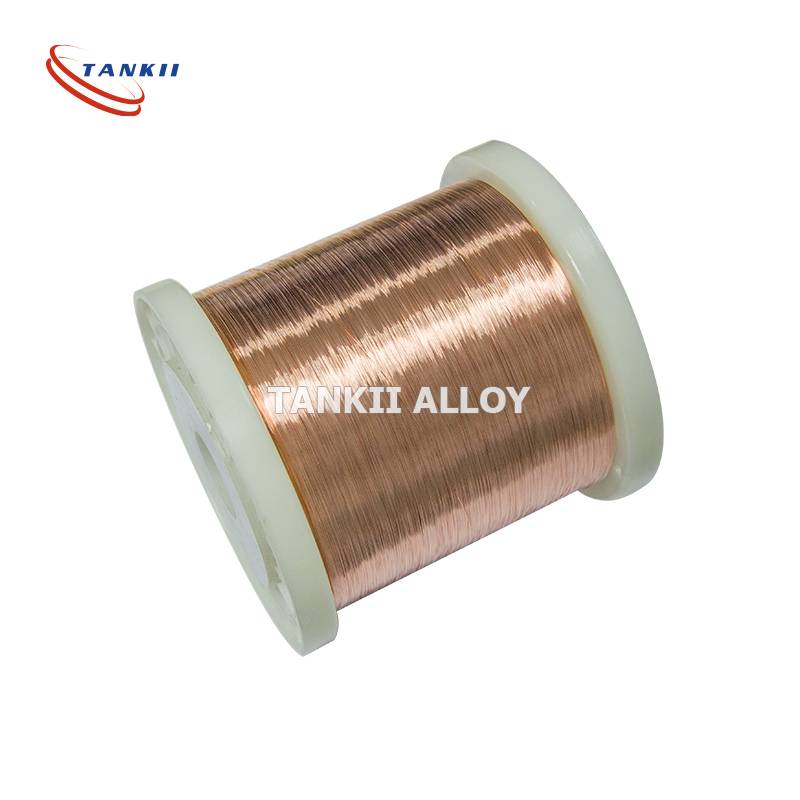

Our items are commonly identified and trusted by customers and may fulfill continuously switching economic and social wants of Alloy 294, Rope Heaters , Nikrothal 60 , Kanthal Af ,Precision And Vitreous Resistors . We guaranteed quality, if customers were not satisfied with the products' quality, you can return within 7days with their original states. The product will supply to all over the world, such as Europe, America, Australia,Luxembourg, Kuwait,Grenada, Doha.Our company sets up several departments, including production department, sales department, quality control department and sevice center,etc. only for accomplish the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment. We always think about the question on the side of the customers,because you win,we win!

Related Products