3kw/6kw/9kw/12kw Electric Industrial Bayonet Heater Bayonet Heating Element For Liquid Heating Element

Product Description of Bayonet Heating Elements Review

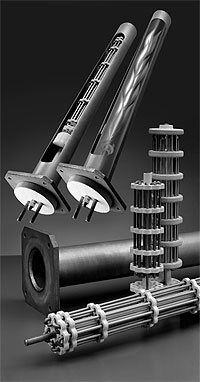

Bayonet heating elements are typically constructed with inline configurations and have electrical plugin “bayonet” connector to facilitate quick installation and removal.Bayonet heating elements are used in industrial processing equipment such as:heat treating,glass production,ion nitriding,salt baths,non-ferrous metals liquefy,scientific applications,seal quench furnaces, hardening furnaces,tempering furnaces,annealing furnaces,and industrial kilns.

Bayonet heating elements are manufactured from a variety of materials,these include chrome,nickel,aluminum and iron wires. Elements can be designed to operate within most environmental conditions.Elements are often encased within protective tubes or sheaf’s for indirect heating applications or where caustic environments may damage the heating elements.bayonet heating elements are available in high wattage capability in small and large packages and sizes in a variety of package configurations.the heating elements assembly can mounted in any orientation.

Bayonets for heat treat furnaces up to 1800°F can be designed for a range of supply voltages and typically don’t require transformers. Compared to gas systems, Bayonets are more efficient (no heat losses), quieter, and typically require less maintenance.

Bayonets can be used with radiant tubes to protect the elements from atmospheric conditions and provide support to prevent deformation. Standard and custom sizes are available.

1. bayonet type heating element, it is characterized in that: comprise the porcelain piece more than 2, described porcelain piece is passed rod iron (5) successively; Be provided with wiring rod (1) in the first porcelain piece (2); Be wound with resistive band (3) between the first porcelain piece (2) and the second porcelain piece; Resistive band (3) one ends connect wiring rod (1) by the first porcelain piece (2), and the other end passes all the other porcelain pieces successively.

2. bayonet type heating element according to claim 1 is characterized in that: described porcelain piece is circular and which is provided with the hole.

3. bayonet type heating element according to claim 2, it is characterized in that: described hole is square hole.

4. bayonet type heating element according to claim 1, it is characterized in that: described porcelain piece has 5.

5. bayonet type heating element according to claim 1, it is characterized in that: described resistive band (3) is wound in cylindrical shape.