Electric Heater element - Manufacturers, Factory, Suppliers from China

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Electric Heater element, Cartridge Elements , Hardening , Cu-Ni 23 ,Alkrothal 720 . We are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to contact us for more detail! The product will supply to all over the world, such as Europe, America, Australia,United Arab Emirates, Panama,Irish, Adelaide.Welcome to visit our company, factory and our showroom where displays various hair products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to provide you the best service. Please contact us if you need more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

Related Products

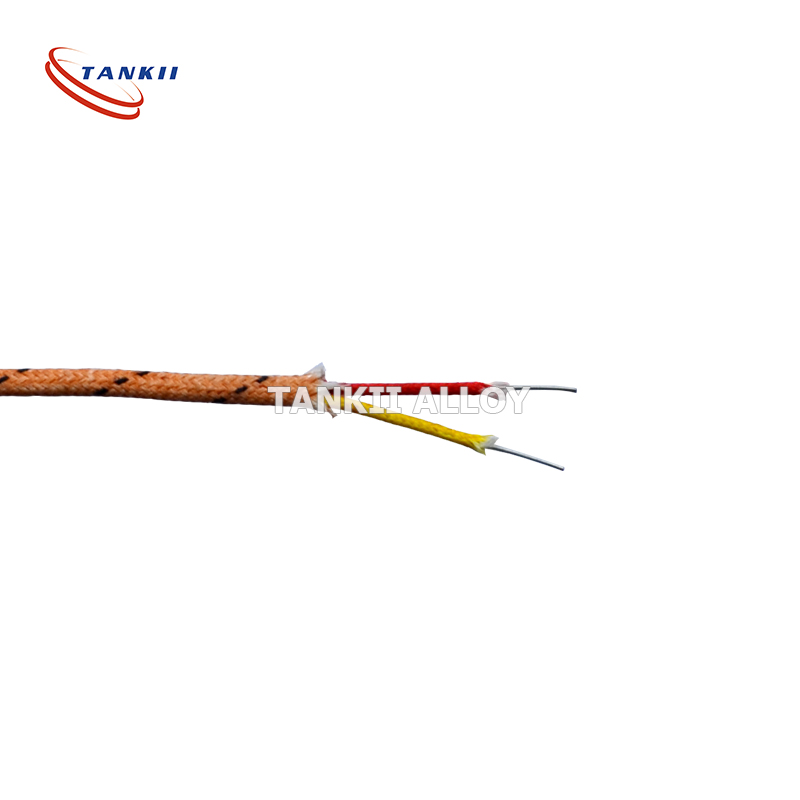

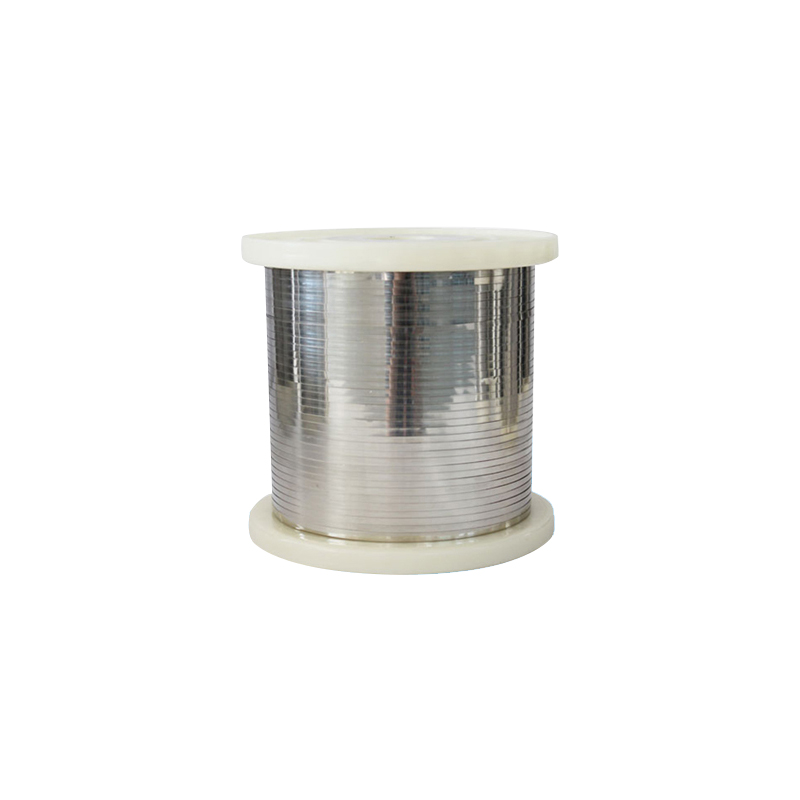

Tankii china supplier customized bayonet electric Heating Element with high quality and best price used in industry

Read More