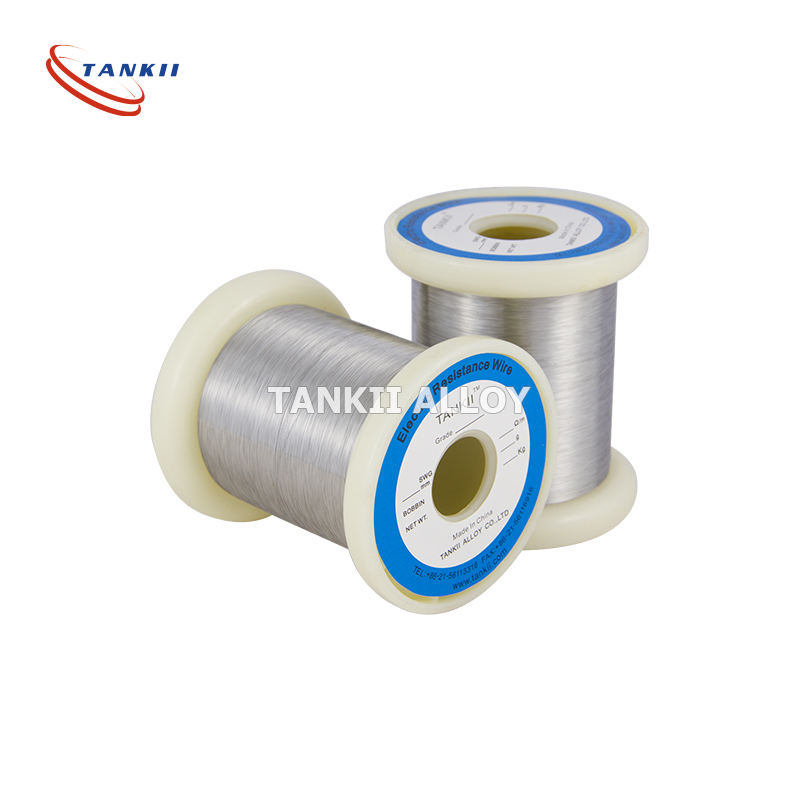

AWG22-40 Ni80cr20 Wire Nickel Chrome 80/20 for Car Seat Heaters

AWG22-40 Ni80cr20 Wire Nickel Chrome 80/20 for Car Seat Heaters

Ni80cr20 is a nickel-chromium alloy (NiCr alloy) characterized by High resistivity, good oxidation resistance,very good form stability,good ductility and excellent weldability. It is suitable for use at temperatures up to 1100°C.

Typical applications for OhmAlloy104B are used in olid hot plates,open coil heaters in HVAC systems,night-storage heaters,convection heaters,heavy duty rheostats and fan heaters. And also used for heating cables and rope heaters in defrosting and de-icing elements,electric blankets and pads, car seats,baseboard heaters,floor heaters and resistors.

Normal composition%

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Other |

| Max | |||||||||

| 0.08 | 0.02 | 0.015 | 1.00 | 1.0~2.0 | 18.0~21.0 | 30.0~34.0 | - | Bal. | - |

Typical Mechanical properties(1.0mm)

| Yield strength | Tensile Strength | Elongation |

| Mpa | Mpa | % |

| 340 | 750 | 20 |

Typical Physical properties

| Density (g/cm3) | 8.4 |

| Electrical resistivity at 20ºC(Ωmm2/m) | 1.09 |

| Conductivity coefficient at 20ºC (WmK) | 13 |

| Coefficient of thermal expansion | |

| Temperature | Coefficient of Thermal Expansion x10-6/ºC |

| 20 ºC- 1000ºC | 18 |

| Specific heat capacity | |

| Temperature | 20ºC |

| J/gK | 0.50 |

| Melting point (ºC) | 1400 |

| Max continuous operating temperature in air (ºC) | 1200 |

| Magnetic properties | non-magnetic |

Temperature Factors Of Electrical Resistivity

| 20ºC | 100ºC | 200ºC | 300ºC | 400ºC | 500ºC | 600ºC |

| 1 | 1.023 | 1.052 | 1.079 | 1.103 | 1.125 | 1.141 |

| 700ºC | 800ºC | 900ºC | 1000ºC | 1100ºC | 1200ºC | 1300ºC |

| 1.158 | 1.173 | 1.187 | 1.201 | 1.214 | 1.226 | - |

Shanghai Tankii Alloy Material Co., Ltd. Focus on the production of resistance alloy(nichrome Alloy, FeCrAl Alloy, copper nickel alloy, thermocouple wire, precision alloy and thermal spray alloy in the form of wire, sheet, tape, strip, rod and plate. We’ve already got ISO9001 quality system certificate and approval of ISO14001 environmental protection system. We own a complete set of advanced production flow of refining, cold reduction, drawing and heat treating etc. We also proudly have independent R&D capacity.

Shanghai Tankii Alloy Material Co., Ltd has accumulated lots of experiences over 35 years in this field. During these years, more than 60 management elites and high science and technology talents were employed. They participated in every walk of the company life, which make our company keep blooming and invincible in the competitive market. Based on the principle of “first quality, sincere service”, our managing ideology is pursuing technology innovation and creating the top brand in the alloy field. We persist in Quality – the foundation of the survival. It is our forever ideology to serve you with full heart and soul. We committed to provide customers all over the world with high-quality, competitive products and perfect service.

Our products, such us nichrome alloy, precision alloy, thermocouple wire, fecral alloy, copper nickel alloy, thermal spray alloy have been exported to over 60 countries in the world. We are willing to establish strong and long-time partnership with our customers. Most complete range of products dedicated to Resistance, Thermocouple and Furnace manufacturers Quality with end to end production control Technical support and Customer Service.