Welcome to our websites!

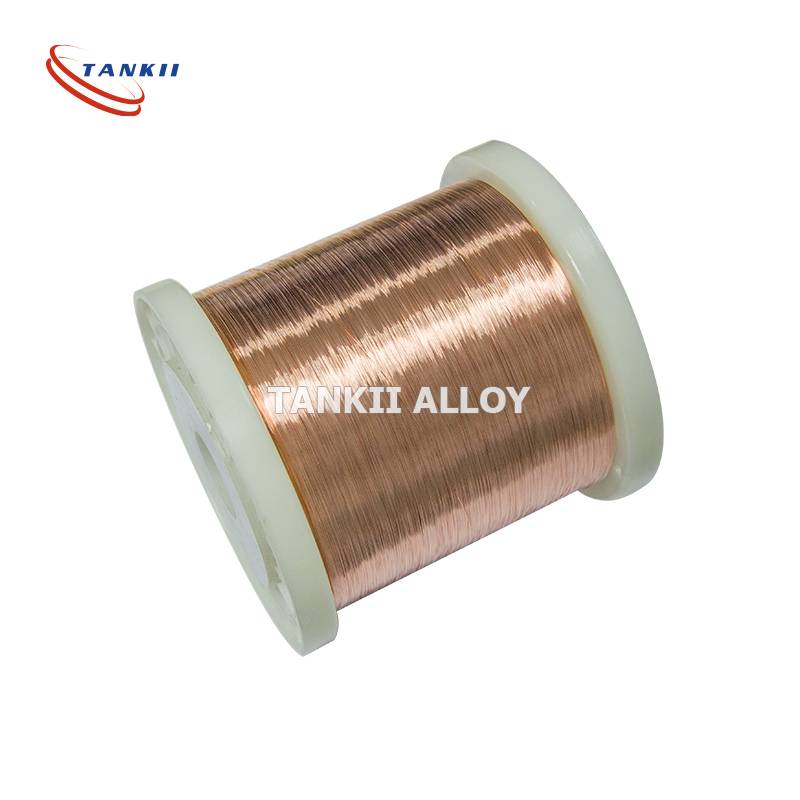

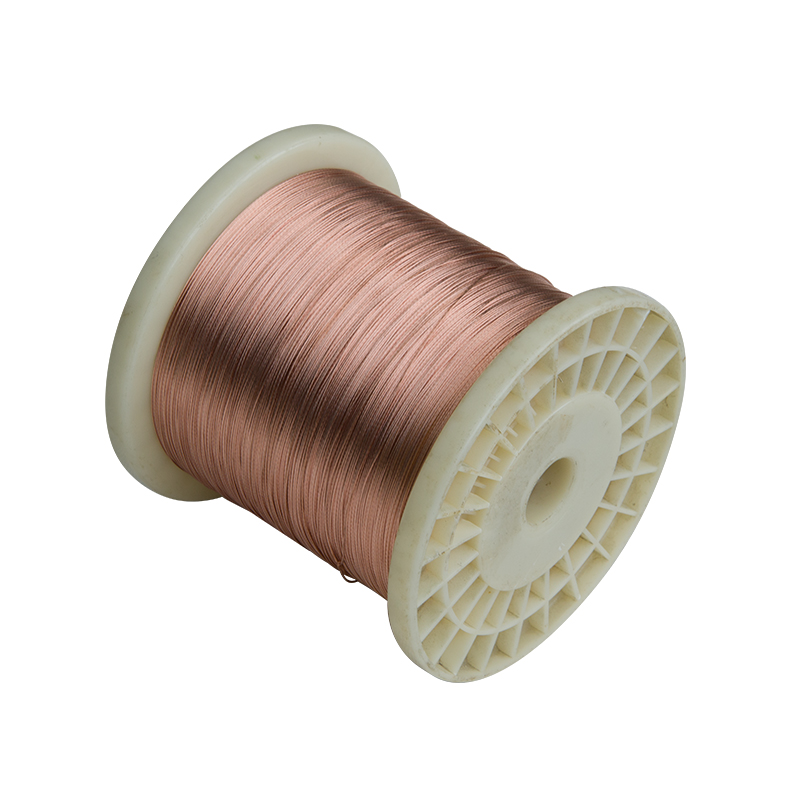

Copper Nickel CuNi23 Stranded Resistance Wire for Heating

Normal composition%

| Nickel | 23 | Manganese | 0.5 |

| Copper | Bal. |

Typical Mechanical properties(1.0mm)

| Yield strength | Tensile Strength | Elongation |

| Mpa | Mpa | % |

| 170 | 350 | 25 |

Typical Physical properties

| Density (g/cm3) | 8.9 |

| Electrical resistivity at 20ºC (Ωmm2/m) | 0.30 |

| Temperature factor of resistivity(20ºC~600ºC)X10-5/ºC | <16 |

| Conductivity coefficient at 20ºC (WmK) | 33 |

| EMF vs Cu(μV/ºC )(0~100ºC ) | -34 |

| Coefficient of thermal expansion | |

| Temperature | Thermal Expansion x10-6/K |

| 20 ºC- 400ºC | 17.5 |

| Specific heat capacity | |

| Temperature | 20ºC |

| J/gK | 0.380 |

| Melting point (ºC) | 1150 |

| Max continuous operating temperature in air (ºC) | 300 |

| Magnetic properties | non-magnetic |

Corrosion resistance performance

| Alloys | Working In atmosphere at 20ºC | Working at max temperature 200ºC | |||||

| Air and oxygen contain gases |

gases with Nitrogen | gases with sulfur oxidability |

gases with sulfur reductibility |

carburization | |||

| Alloy 180 | good | general | general | general | bad | good | |

Write your message here and send it to us