Fan Heating Coils - Factory, Suppliers, Manufacturers from China

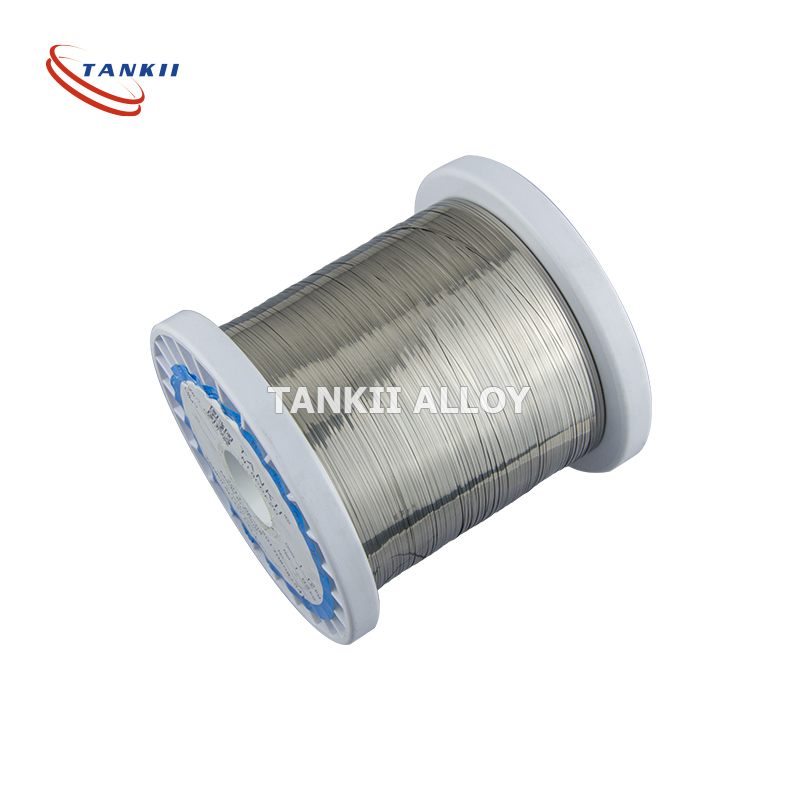

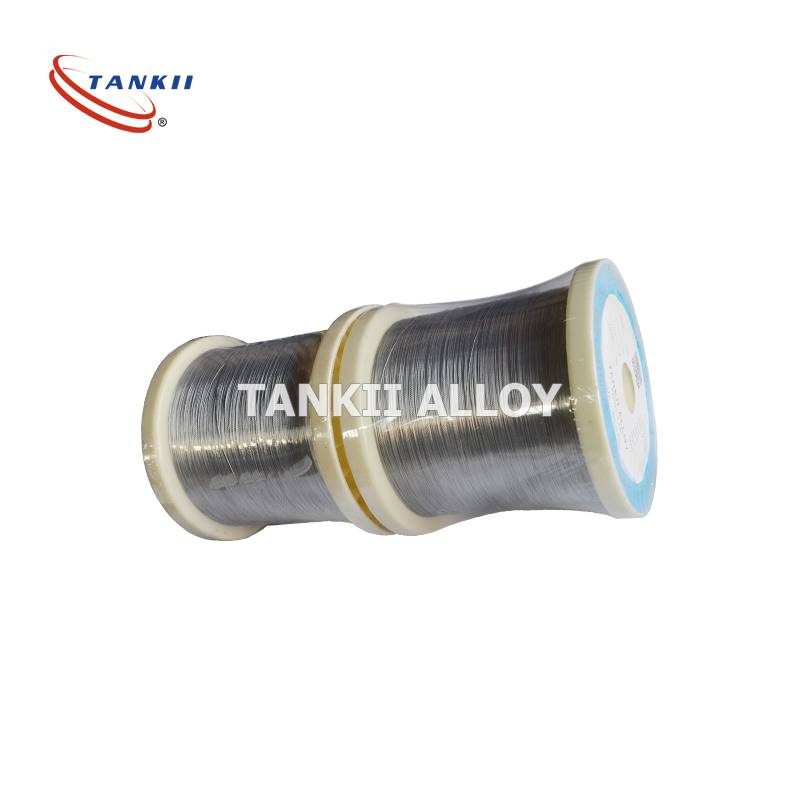

We purpose to understand high quality disfigurement with the output and supply the top service to domestic and overseas buyers wholeheartedly for Fan Heating Coils, Ion Nitriding , Helical Wound Nickel Chromium Resistance Wires , Alloy 290 ,Tank Heating . "Making the Products of High Quality" is the eternal goal of our company. We make unremitting efforts to realize the goal of "We Will Always Keep in Pace with the Time". The product will supply to all over the world, such as Europe, America, Australia,Mongolia, Poland,Mozambique, Kuwait.Our company always concentrate on the development of the international market. We now have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

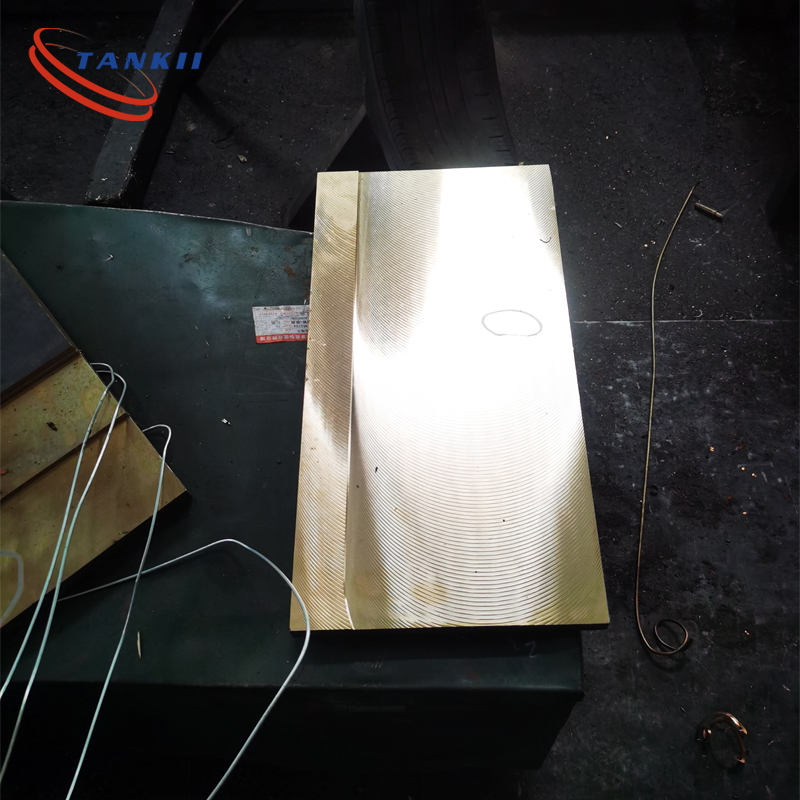

Related Products