Welcome to our websites!

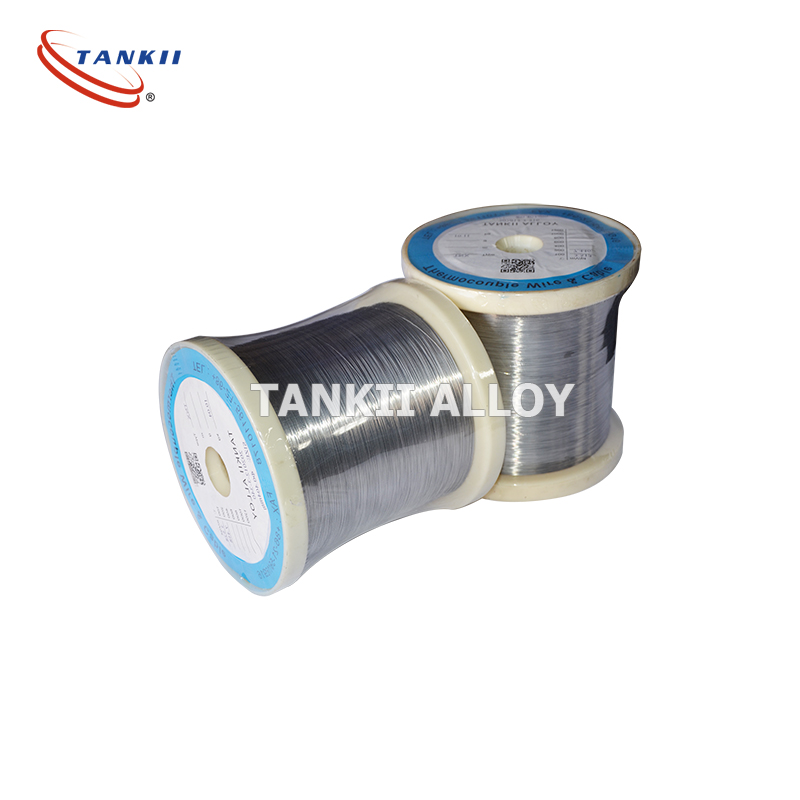

Ni95Al5 Thermal Spray Wire / 955 Nickel-Aluminum Bond Coat Wire

Product Name

Ni95Al5 Thermal Spray Wire / 955 Nickel-Aluminum Bond Coat Wire

Grade / Equivalent

NiAl 955, Ni95Al5, TAFA 75B, PMET 885, MEC 885

NiAl 955, Ni95Al5, TAFA 75B, PMET 885, MEC 885

Wire Chemistry (wt %)

Ni ≥ 95 | Al 4-5 | C ≤ 0.02 | Mn ≤ 0.2 | Si ≤ 0.2 | Fe ≤ 0.5 | O ≤ 0.005 | Others ≤ 0.5

Ni ≥ 95 | Al 4-5 | C ≤ 0.02 | Mn ≤ 0.2 | Si ≤ 0.2 | Fe ≤ 0.5 | O ≤ 0.005 | Others ≤ 0.5

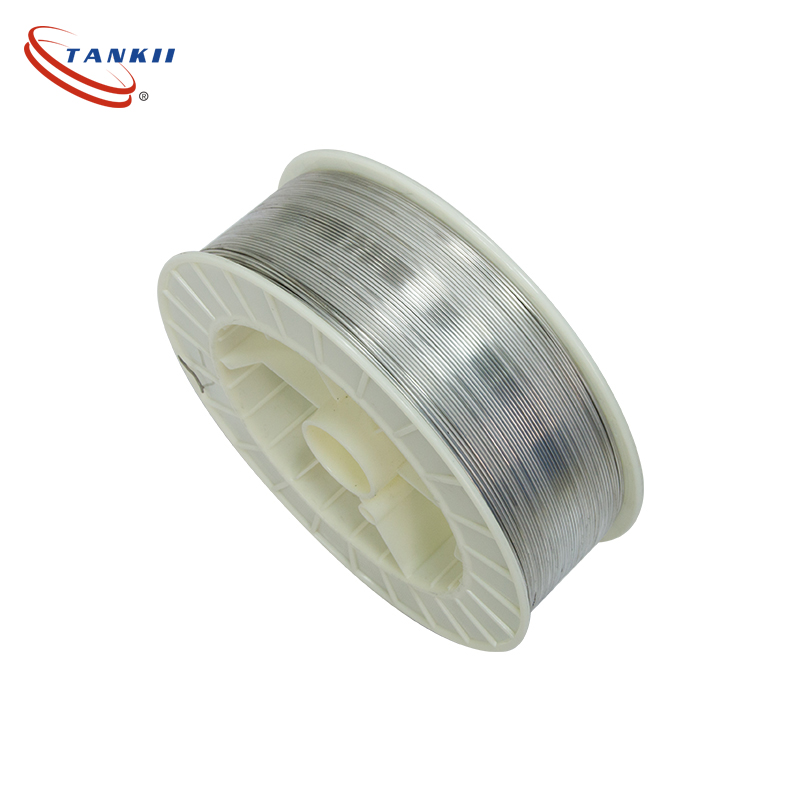

Available Diameters & Tolerance

1.6 mm (-0 / +0.05 mm) | 2.0 mm (-0 / +0.05 mm)

Other sizes on request.

1.6 mm (-0 / +0.05 mm) | 2.0 mm (-0 / +0.05 mm)

Other sizes on request.

Typical Physical & Spray Properties

-

Density: 8.83 g cm⁻³

-

Elongation: 40 %

-

Max. service temperature: 1 300 °C (short-term 1 390 °C)

-

As-sprayed hardness: 200-260 HV

-

Bond strength on mild steel: ≥ 55 MPa

-

Oxide content after spraying: ≤ 3 %

-

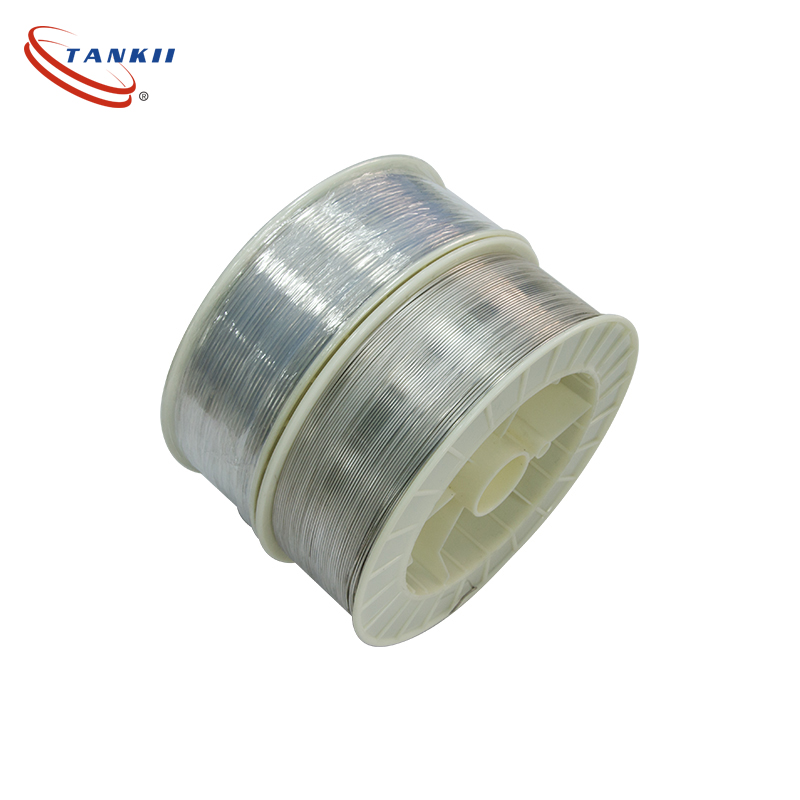

Surface finish: bright, smooth, free of draw-marks

Key Coating Characteristics

✔ Ultra-dense microstructure, porosity < 2 %

✔ Self-bonding to most iron & nickel-base substrates (no intermediate layer required)

✔ Forms in-situ Al₂O₃ scale → excellent high-temperature oxidation & corrosion resistance

✔ Outstanding thermal-shock & scuff resistance

✔ Ultra-dense microstructure, porosity < 2 %

✔ Self-bonding to most iron & nickel-base substrates (no intermediate layer required)

✔ Forms in-situ Al₂O₃ scale → excellent high-temperature oxidation & corrosion resistance

✔ Outstanding thermal-shock & scuff resistance

Recommended Spray Parameters (Arc-Spray)

Voltage: 30-34 V | Current: 120-180 A | Air pressure: 0.55-0.65 MPa

Stand-off distance: 150-200 mm | Traverse speed: 200-400 mm s⁻¹

Voltage: 30-34 V | Current: 120-180 A | Air pressure: 0.55-0.65 MPa

Stand-off distance: 150-200 mm | Traverse speed: 200-400 mm s⁻¹

Main Applications

-

Bond coat for ceramic top-coats (ZrO₂, Al₂O₃, Cr₂O₃) on gas-turbine blades, piston rods, boiler tubes

-

Corrosion-resistant under-layer for chemical pump shafts, fan impellers, marine propellers

-

Restoration of worn glass-moulds, forging dies, paper dryer rolls

-

EMI shielding & conductive coatings in electronic housings

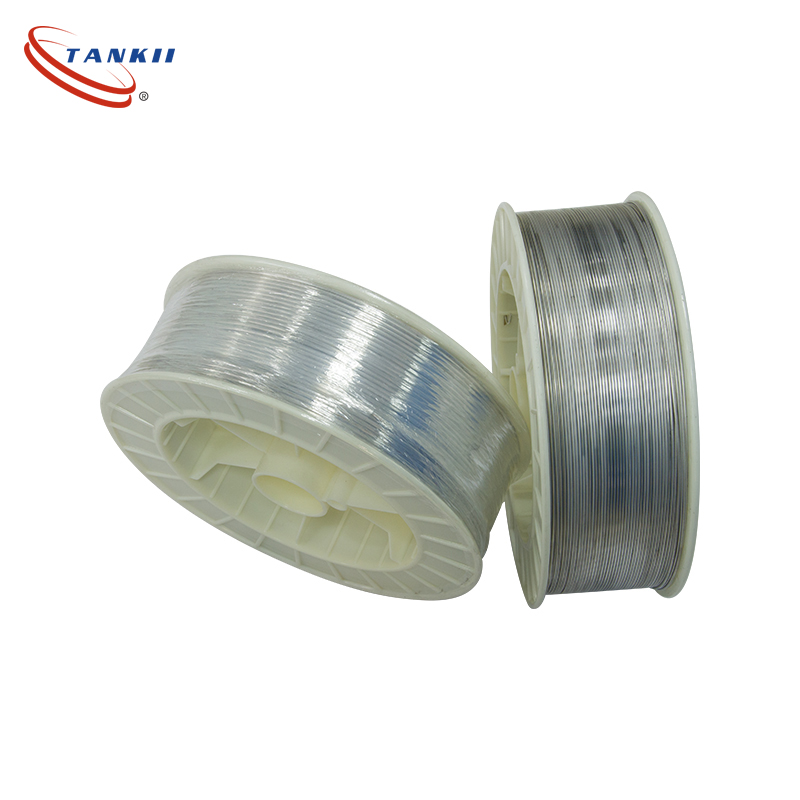

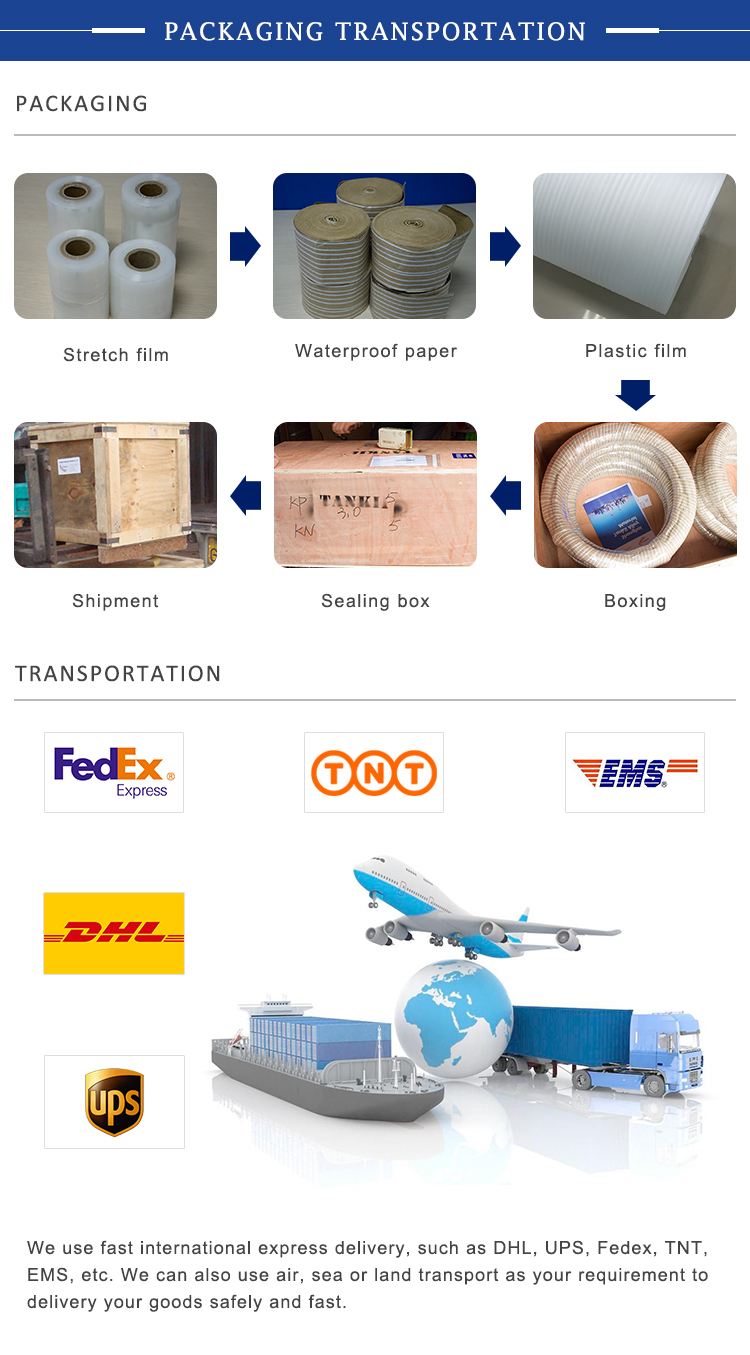

Packaging Options

-

15 kg / 25 kg plastic spool (DIN 300) + vacuum foil + export carton

-

50-250 kg steel coil, PE-wrapped + wooden pallet

-

Custom labelling & bar-coding available

Standards Conformance

AMS 4778, ASTM B833, ISO 14919, GB/T 30566

AMS 4778, ASTM B833, ISO 14919, GB/T 30566

Shelf Life & Storage

5 years in original unopened packaging; store < 25 °C, RH < 60 %, away from acids & sulphur.

5 years in original unopened packaging; store < 25 °C, RH < 60 %, away from acids & sulphur.

MOQ & Lead Time

15 kg; 3-5 days ex-factory for ≤ 500 kg, 7-10 days for ≤ 2 t.

15 kg; 3-5 days ex-factory for ≤ 500 kg, 7-10 days for ≤ 2 t.

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top