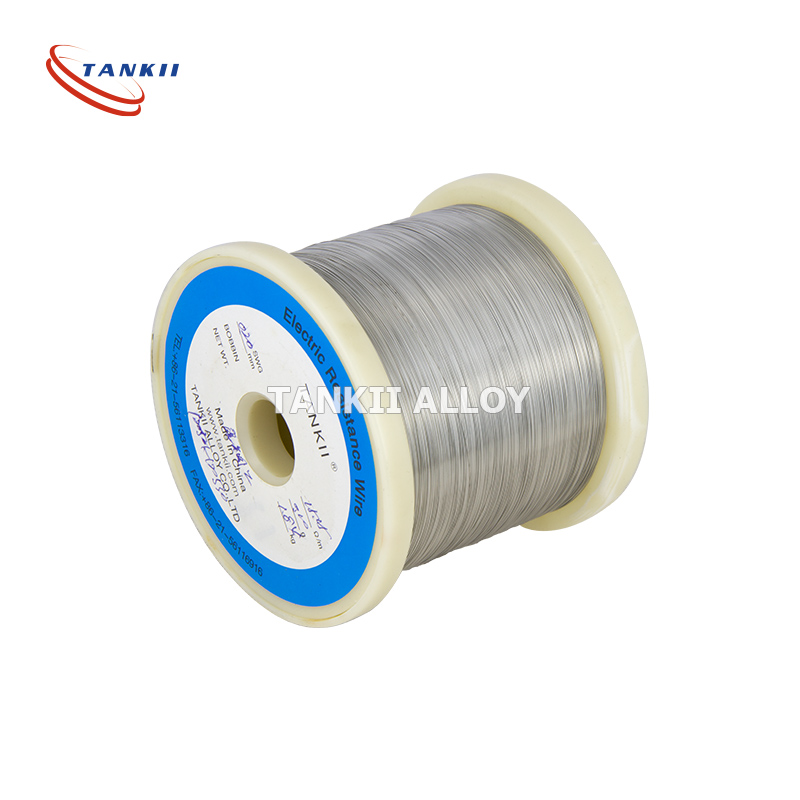

Resistance wire NiCr8020 /nichrome alloy /ni80cr20 wire nicr alloy wire

Resistance wire NiCr8020 /nichrome alloy /ni80cr20 wire nicr alloy wire

Nikrothal8 ,MWS-650, NiCrA, Tophet A, HAI-NiCr 80, Chromel A, Alloy A, Alloy 650, N8, Resistohm 80, Stablohm 650, Nichorme V, Nikrothal 80.

Ni80Cr20 is a nickel-chromium alloy (NiCr alloy) characterized by high resistivity, good oxidation resistance and very good form stability. It is suitable for use at temperatures up to 1200°C,and hold a superior service life compared to Iron chromium alumium alloys.

Typical applications for Ni80Cr20 are electric heating elements in home appliances,industrial furnaces and resistors(wirewound resistors,metal film resistors), flat irons, ironing machines, water heaters, plastic moulding dies, soldering irons, metal sheathed tubular elements and cartridge elements.

Normal composition%

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Other |

| Max | |||||||||

| 0.03 | 0.02 | 0.015 | 0.60 | 0.75~1.60 | 20.0~23.0 | Bal. | Max 0.50 | Max 1.0 | - |

Typical Mechanical properties(1.0mm)

| Yield strength | Tensile Strength | Elongation |

| Mpa | Mpa | % |

| 420 | 810 | 30 |

Typical Physical properties

| Density (g/cm3) | 8.4 |

| Electrical resistivity at 20ºC(Om*mm2/m) | 1.09 |

| Conductivity coefficient at 20ºC (WmK) | 15 |

| Coefficient of thermal expansion | |

| Temperature | Coefficient of Thermal Expansion x10-6/ºC |

| 20 ºC- 1000ºC | 18 |

| Specific heat capacity | |

| Temperature | 20ºC |

| J/gK | 0.46 |

| Melting point (ºC) | 1400 |

| Max continuous operating temperature in air (ºC) | 1200 |

| Magnetic properties | non-magnetic |

| Temperature Factors Of Electrical Resistivity | |||||

| 20ºC | 100ºC | 200ºC | 300ºC | 400ºC | 600ºC |

| 1 | 1.006 | 1.012 | 1.018 | 1.025 | 1.018 |

| 700ºC | 800ºC | 900ºC | 1000ºC | 1100ºC | 1300ºC |

| 1.01 | 1.008 | 1.01 | 1.014 | 1.021 | - |

Style of supply

| Alloys Name | Type | Dimension | ||

| OhmAlloy109W | Wire | D=0.03mm~8mm | ||

| OhmAlloy109R | Ribbon | W=0.4~40mm | T=0.03~2.9mm | |

| OhmAlloy109S | Strip | W=8~250mm | T=0.1~3.0mm | |

| OhmAlloy109F | Foil | W=6~120mm | T=0.003~0.1mm | |

| OhmAlloy109B | Bar | Dia=8~100mm | L=50~1000mm | |