Welcome to our websites!

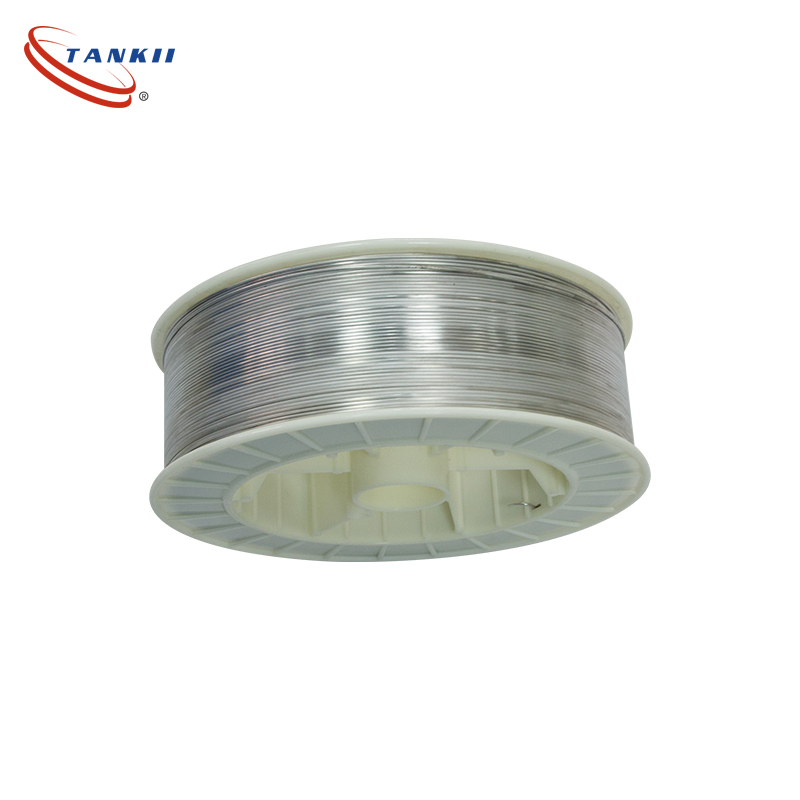

Pmet 885/Tafa75b/Ni95al5 Arc/Flame Spraying Wire Welding Wire for Boiler

Ni95Al5 Nickel-Aluminum Alloy Thermal Spray Wire / Bond Coat Wire

Product Overview

Ni95Al5 (also known as NiAl 95/5, TAFA 75B, Metco 8400, PMET 885, F-80NA, or N9) is a nickel-aluminum alloy containing 95% nickel and 5% aluminum, designed specifically for thermal spray applications. It is characterized by dense coating formation, high-temperature oxidation resistance, thermal shock resistance, and exceptional bonding strength. This self-bonding alloy is widely used as a bond coat to improve adhesion between substrates and top coatings, or as a standalone protective coating.

| Element | Content (%) |

|---|---|

| Nickel (Ni) | Balance (93.0% min) |

| Aluminum (Al) | 4.5 – 5.5% |

| Manganese (Mn) | ≤0.3% |

| Iron (Fe) | ≤0.3% |

| Silicon (Si) | ≤0.5% |

| Copper (Cu) | ≤0.08% |

| Carbon (C) | ≤0.005% |

| Titanium (Ti) | ≤0.3-0.4% |

| Property | Value |

|---|---|

| Density | 7.8 – 8.2 g/cm³ |

| Melting Point | 1010°C – 1430°C |

| Electrical Resistivity (20°C) | 0.42 μΩ·m |

| Tensile Strength | 500 MPa |

| Coating Hardness | HRB 75 / 23-25 HRC |

| Bond Strength | 55-68 MPa / 9,000-10,000 psi |

| Deposit Rate | 10 lbs/hr/100A |

| Deposit Efficiency | 60-70% |

| Maximum Service Temperature | 700-800°C (air) |

| Magnetic Properties | Non-magnetic |

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top