PriceList for Industrial Furnaces - Iron Chrome Aluminum Resistance Alloys – TANKII

PriceList for Industrial Furnaces - Iron Chrome Aluminum Resistance Alloys – TANKII Detail:

Iron Chrome Aluminum (FeCrAl) alloys are high-resistance materials typically used in applications with maximum operating temperatures up to 1,400°C (2,550°F).

These Ferritic alloys are known to have higher surface loading capability, higher resistivity and lower density than Nickel Chrome (NiCr) alternatives which can translate to less material in application and weight savings. The higher maximum operating temperatures can also lead to longer element life. Iron Chrome Aluminum alloys form a light grey Aluminum Oxide (Al2O3) at temperatures above 1,000°C (1,832°F) which increases corrosion resistance as well as acts as an electrical insulator. The oxide formation is considered self-insulating and protects against short circuiting in the event of metal to metal contact. Iron Chrome Aluminum alloys have lower mechanical strength when compared to Nickel Chrome materials as well as lower creep strength.

Specification of Cold-drawing Round Type heating wire

|

Diameter(mm) |

Tolerance(mm) |

Diameter(mm) |

Tolerance(mm) |

|

0.03-0.05 |

±0.005 |

>0.50-1.00 |

±0.02 |

|

>0.05-0.10 |

±0.006 |

>1.00-3.00 |

±0.03 |

|

>0.10-0.20 |

±0.008 |

>3.00-6.00 |

±0.04 |

|

>0.20-0.30 |

±0.010 |

>6.00-8.00 |

±0.05 |

|

>0.30-0.50 |

±0.015 |

>8.00-12.0 |

±0.4 |

Specification of Cold-drawing Strip Type heating wire

|

Thickness(mm) |

Tolerance(mm) |

Width(mm) |

Tolerance(mm) |

|

0.05-0.10 |

±0.010 |

5.00-10.0 |

±0.2 |

|

>0.10-0.20 |

±0.015 |

>10.0-20.0 |

±0.2 |

|

>0.20-0.50 |

±0.020 |

>20.0-30.0 |

±0.2 |

|

>0.50-1.00 |

±0.030 |

>30.0-50.0 |

±0.3 |

|

>1.00-1.80 |

±0.040 |

>50.0-90.0 |

±0.3 |

|

>1.80-2.50 |

±0.050 |

>90.0-120.0 |

±0.5 |

|

>2.50-3.50 |

±0.060 |

>120.0-250.0 |

±0.6 |

|

Alloy Type |

Diameter |

Resistivity |

Tensile |

Elongation(%) |

Bending |

Max.Continuous |

Working Life |

|

1Cr13Al4 |

0.03-12.0 |

1.25±0.08 |

588-735 |

>16 |

>6 |

950 |

>10000 |

|

0Cr15Al5 |

1.25±0.08 |

588-735 |

>16 |

>6 |

1000 |

>10000 |

|

|

0Cr25Al5 |

1.42±0.07 |

634-784 |

>12 |

>5 |

1300 |

>8000 |

|

|

0Cr23Al5 |

1.35±0.06 |

634-784 |

>12 |

>5 |

1250 |

>8000 |

|

|

0Cr21Al6 |

1.42±0.07 |

634-784 |

>12 |

>5 |

1300 |

>8000 |

|

|

1Cr20Al3 |

1.23±0.06 |

634-784 |

>12 |

>5 |

1100 |

>8000 |

|

|

0Cr21Al6Nb |

1.45±0.07 |

634-784 |

>12 |

>5 |

1350 |

>8000 |

|

|

0Cr27Al7Mo2 |

0.03-12.0 |

1.53±0.07 |

686-784 |

>12 |

>5 |

1400 |

>8000 |

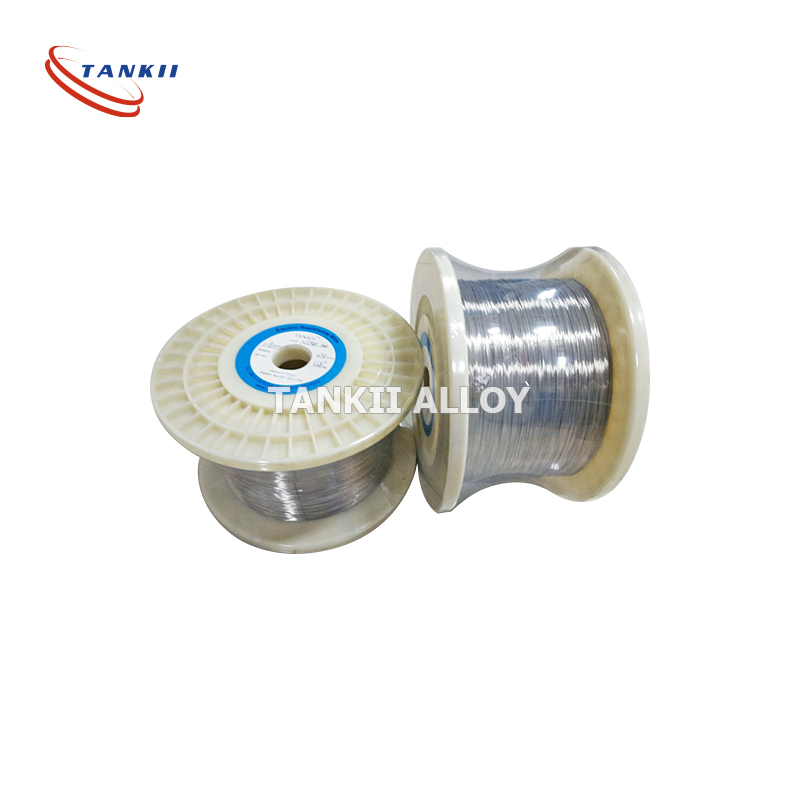

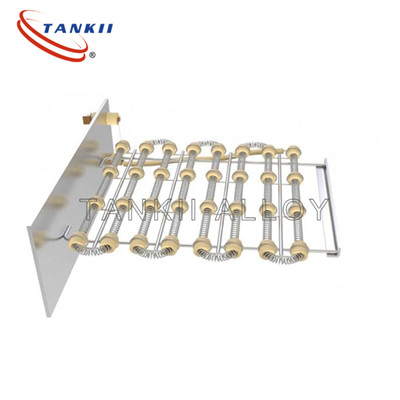

Product detail pictures:

Related Product Guide:

We emphasize progress and introduce new merchandise into the market each and every year for PriceList for Industrial Furnaces - Iron Chrome Aluminum Resistance Alloys – TANKII , The product will supply to all over the world, such as: Lesotho, Kyrgyzstan, Bolivia, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We are able to also provide you with no cost samples to meet your needs. Best efforts will be produced to offer you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our products and enterprise. lot more, you'll be able to come to our factory to find out it. We will constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. Please really feel absolutely free to make contact with us for small business and we believe we will share the top trading practical experience with all our merchants.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top