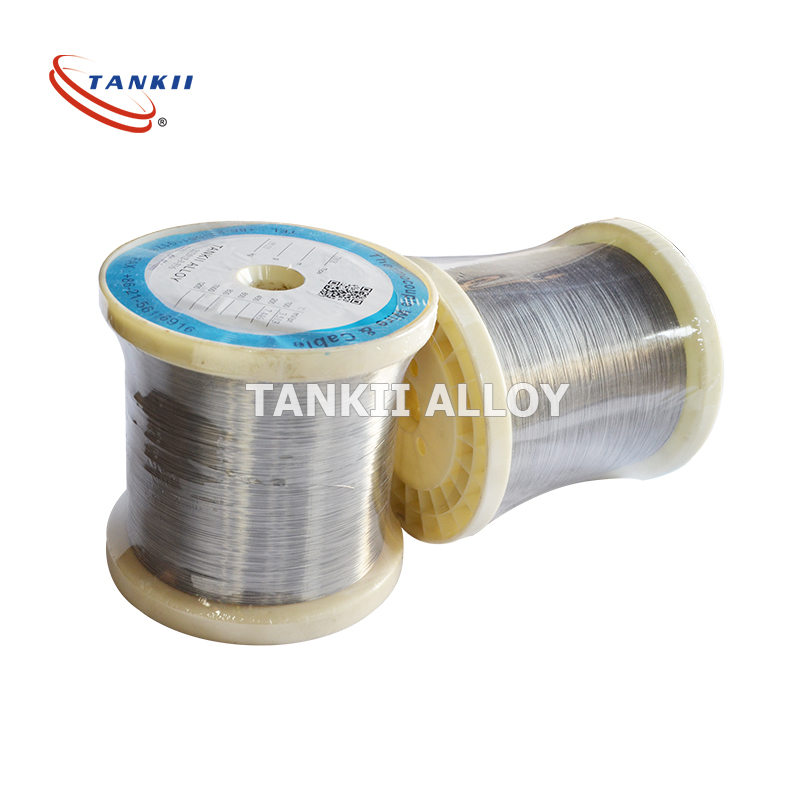

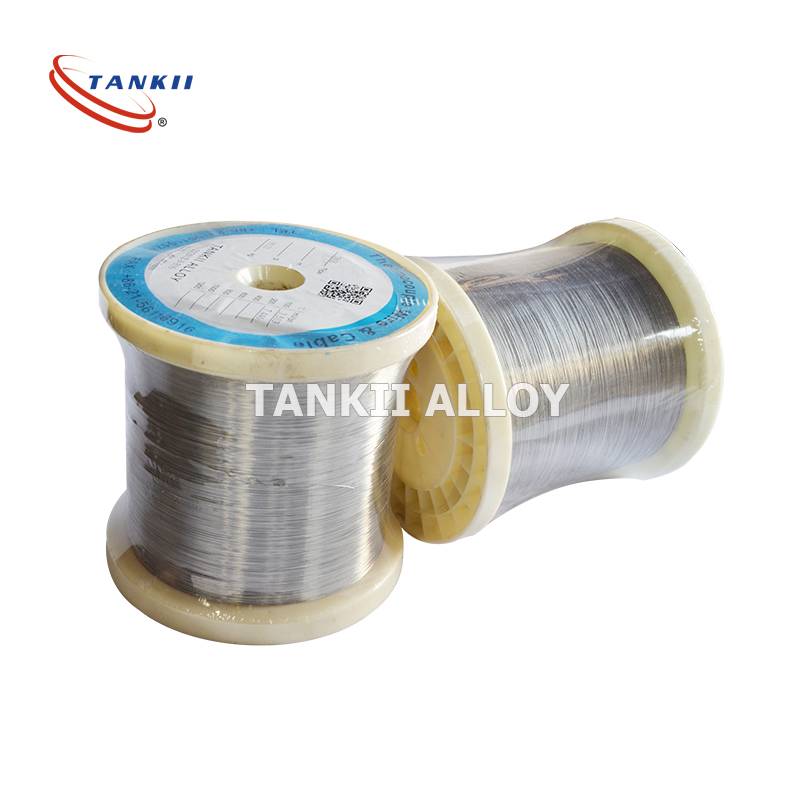

Radiator Heat Resistant 0cr25al5 Alloy Wire Fecral resistance wire

Radiator Resistance Heating Wire Fecral 0cr25al5 Alloy In Silver Grey Color

1. Detailed Description

FeCrAl Alloy, 1Cr13Al4, 0Cr23Al5, 0Cr25Al5, 0Cr20Al6RE, 0Cr21Al6Nb, 0Cr27Al7Mo2

FeCrAl Alloy is a ferritic iron-chromium-aluminum alloy (FeCrAl alloy) for use in arc and flame spray systems. The alloy produces dense, well bonding coatings, resistant to high-temperature oxidation and corrosion.

Application or Properties: Spray wire with excellent bonding strength. Sprayed layers of this material are-resistant to variation in high temperatures and are used as a buffer layer for all other spraying alloys.

0Cr25Al5

0Cr25Al5 is a ferritic iron-chromium-aluminum alloy (FeCrAl alloy) for use in arc and flame spray systems. The alloy produces dense, well bonding coatings, resistant to high-temperature oxidation and corrosion.

2. Mechanical Properties

| Max Continuous Service Temp | 980ºC |

| Resisivity at 20ºC | 1.28 ohm mm2/m |

| Density | 7.4 g/cm3 |

| Thermal Conductivity | 52.7 KJ/m@h@ºC |

| Coefficient of Thermal Expansion | 15.4×10-6/ºC |

| Melting Point | 1450ºC |

| Tensile Strength | 637~784 Mpa |

| Elongation | Min 12% |

| Section Variation Shrink Rate | 65~75% |

| Repeatedly Bend Frequency | Min 5 times |

| Continuous Service Time | - |

| Hardness | 200-260HB |

| Micrographic Structure | Ferrite |

| Magnetic Property | Magnetic |

3. Features

Stable performance; Anti-oxidation; Corrosion resistance; Low expansion coefficient; High temperature stability; Excellent coil-forming ability; High surface load; Uniform and beautiful surface condition without spots

4. Products and services

1). Pass: ISO9001 certification, and SO14001certification;

2). Fine after-sale services;

3). Small order accepted;

4). Stable properties in high temperature;

5). Fast delivery.

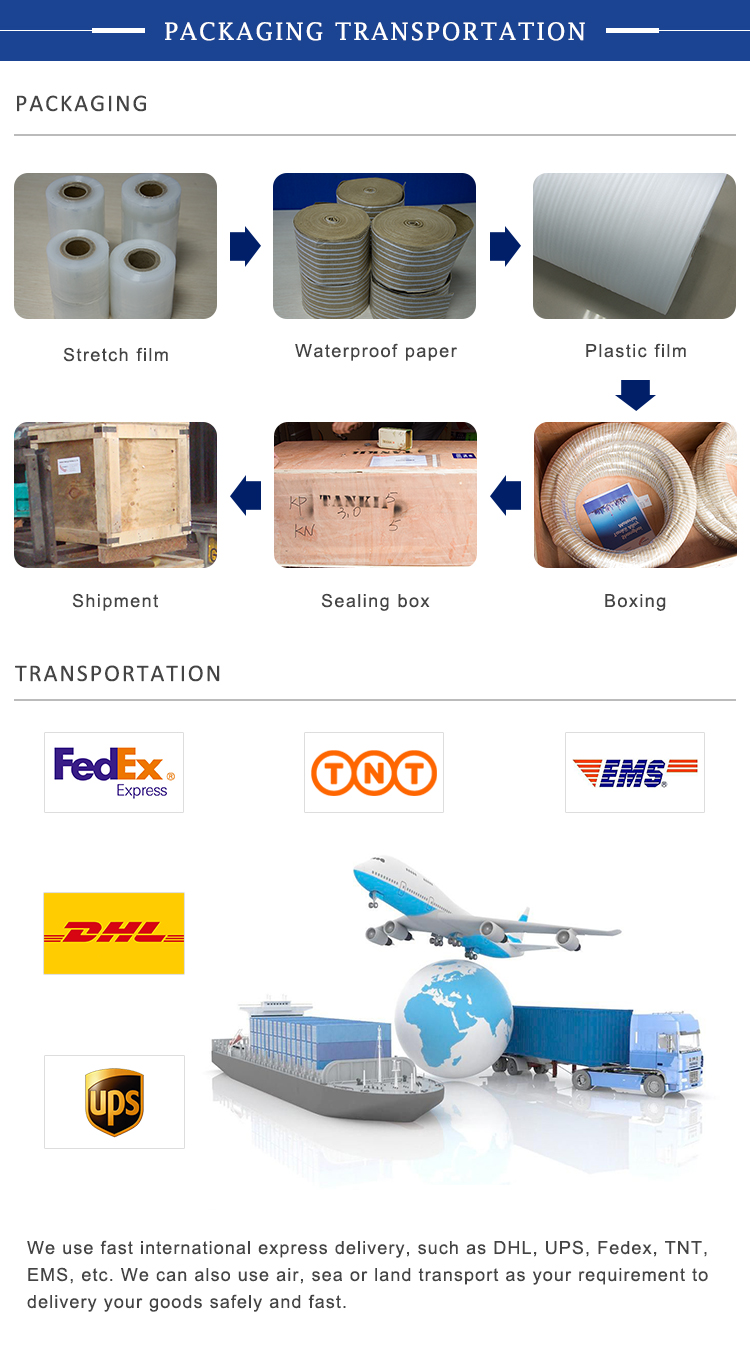

6). Spool, coil, carton, wooden case with plastic film or other wrapping paper according to per client´s requirements.

5. Temperature Factor of Electrical Resistivity

| 20ºC | 100ºC | 200ºC | 300ºC | 400ºC | 500ºC | 600ºC | 700ºC | 800ºC | 900ºC | 1000ºC |

| 1 | 1.005 | 1.014 | 1.028 | 1.044 | 1.064 | 1.090 | 1.120 | 1.132 | 1.142 | 1.150 |

6. Chemical Composition

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Other | ||

| Max | |||||||||||

| 0.12 | 0.025 | 0.025 | 0.70 | Max 1.0 | 13.0~15.0 | Max 0.60 | 4.5~6.0 | Bal. | - | ||

If you are interested, pls do not hesitate to contact us.