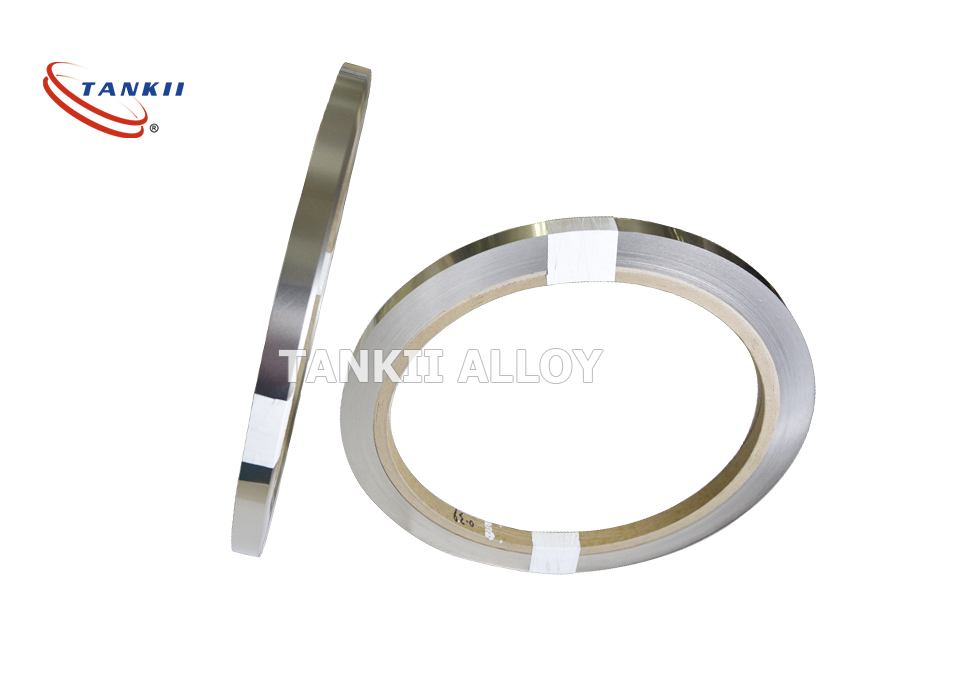

Strip Coil of 0.05mm Thickness FeCrAl resistance wire

FeCrAl Alloy Foil/ Strip Coil 0.05mm Thickness for Metallic Honeycomb Substrates

The high aluminum content, in combination with the high chromium content causes the scaling temperature to increase up to 1425 C (2600F ); Under the headline heat resistance, these FeCrAl alloys are compared with commonly used Fe and Ni base alloys. As can be seen from that table, the FeCrAl alloys have superior properties as compared to the other alloys in most environments.

It should be noted that, during alternating temperature conditions, the yttrium addition to the AF alloy which also is known as the Fecralloys alloys, improves the adherence of the protecting oxide, making the service life of components in the AF alloy longer than that of the A-1 grade.

Fe-Cr-Al alloy wires are made of iron chromium aluminum base alloys containing small amounts of reactive elements such as yttrium and zirconium and produced by smelting, steel rolling, forging, annealing, drawing, surface treatment, resistance control test, etc.

Fe-Cr-Al wire was shaped by means of high speed automatic cooling machine of which the power capacity is controlled by computer, they are available as wire and ribbon(strip).

Features and advantages

1. High using temperature, the maximum using temperature can reach 1400C (0Cr21A16Nb, 0Cr27A17Mo2, etc.)

2. Low temperature coefficient of resistance

3. Lower thermal expansion coefficient than the Ni-base super-alloys.

4. High electrical resistivity

5. Good corrosion resistance under high temperature, especially under the atmosphere containing sulfides

6. High surface load

7. Creep-resistant

8. Lower raw-material cost, Lower density and cheaper price compared with Nichrome wire.

9. Superior oxidation resistance at 800-1300ºC

10. Long service life

The formation of metastable alumina phases due to the oxidation of commercial FeCrAl alloy wires (0.5 mm thickness) at various temperatures and time periods has been examined. Samples were isothermally oxidised in air using a thermogravimetric analyzer (TGA). The morphology of the oxidised samples was analyzed using an Electronic Scanning Electron Microscope (ESEM) and X-ray on the surface analysis was done using an Energy Dispersive X-Ray (EDX) analyzer. The technique of X-Ray Diffraction (XRD) was used to characterize the phase of the oxide growth. The entire study showed that it was possible to grow high-surface area gamma alumina on the FeCrAl alloy wire surfaces when isothermally oxidised above 800°C over several hours.

| Iron Chrome Aluminum | |||||||

| OCr25Al5 | CrAl25-5 | 23.0 | 71.0 | 6.0 | |||

| OCr20Al5 | CrAl20-5 | 20.0 | 75.0 | 5.0 | |||

| OCr27Al7Mo2 | 27.0 | 65.0 | 0.5 | 7.0 | 0.5 | ||

| OCr21Al6Nb | 21.0 | 72.0 | 0.5 | 6.0 | 0.5 | ||

| Iron Chrome Aluminum | ||

| OCr25Al5 | Can be used in operating conditions up to 1350°C, although can become embrittled. | Heating elements of high temperature furnaces and radiant heaters. |

| OCr20Al5 | A ferromagnetic alloy which can be used at temperatures up to 1300°C. Should be operated in dry surroundings to avoid corrosion. Can become embrittled at high temperatures. | Heating elements of high temperature furnaces and radiant heaters. |