Welcome to our websites!

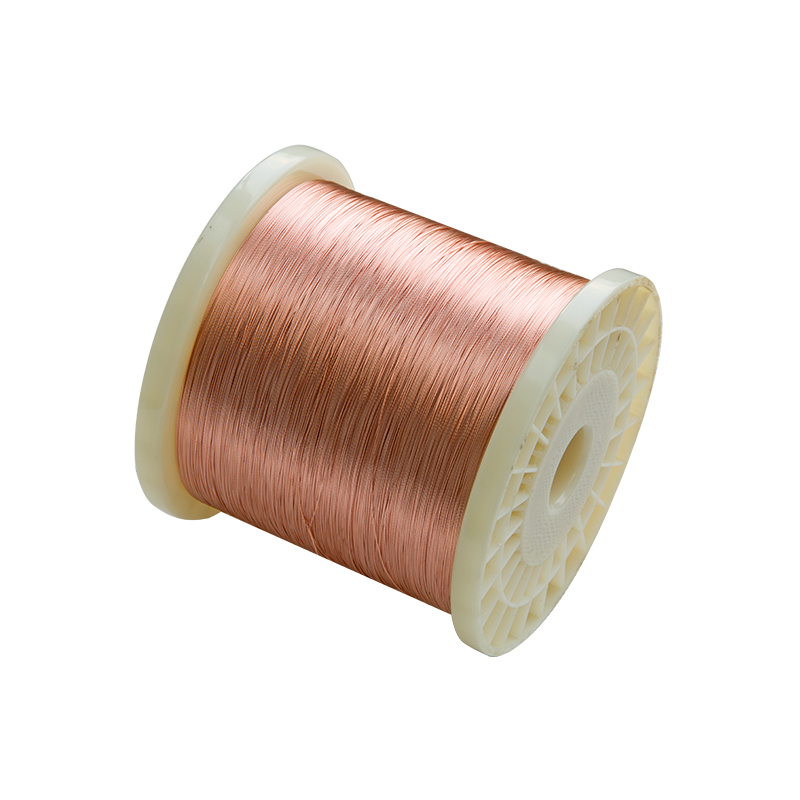

Tankii 1.0mm Tinned Copper Wire T2 Red Copper Anti-Oxidation & Excellent Conductivity

Product Description

1.0mm Tinned Copper Wire (Pure Red Copper Core, 3-5μ Tin Coating)

Product Overview

As a high-reliability electrical conductor from Tankii Alloy Material, the 1.0mm tinned copper wire integrates two core advantages: the ultra-high conductivity of pure red copper (T2 grade) and the anti-corrosion protection of a precision 3-5μ tin coating. Manufactured via Huona’s advanced continuous hot-dip tinning process—equipped with real-time thickness monitoring and temperature control—the wire ensures the tin layer adheres uniformly to the 1.0mm solid copper core, no pits or thin spots. It solves two key pain points of bare copper wire: oxidation-induced conductivity decline and poor solderability, making it a staple for electrical connections requiring long-term stability, easy assembly, and resistance to humid/industrial environments.

Standard & Material Certifications

- Conductor Grade: T2 pure red copper (complies with GB/T 3956-2008; equivalent to ASTM B33, IEC 60288 Class 1)

- Tin Coating Standard: GB/T 4910-2009, IEC 60317-2 (lead-free: Pb ≤0.005%, Sn ≥99.9%)

- Quality Certifications: RoHS 2.0 compliant, ISO 9001 quality management system, SGS environmental testing approval

- Manufacturer: Tankii Alloy Material (15+ years of copper conductor processing experience)

Core Performance Advantages

1. Pure Red Copper Conductor: Unmatched Conductivity

- Electrical Conductivity: ≥98% IACS (20℃), far exceeding alloyed copper (e.g., CuNi alloys: ~20% IACS) and aluminum (61% IACS). Ensures minimal voltage drop in low-voltage circuits (e.g., 12V automotive wiring, 5V USB cables) and fast signal transmission for sensors.

- Mechanical Ductility: Elongation ≥30% (25℃) and tensile strength ≥200 MPa. Can withstand repeated bending (180° bend test ≥10 times without breaking) for wiring in tight spaces (e.g., appliance internal compartments, PCB edge connections).

2. 3-5μ Precision Tin Coating: Targeted Protection

- Anti-Oxidation Barrier: Dense tin layer blocks air/moisture from contacting copper, preventing the formation of conductive copper oxide (CuO/Cu₂O). Even in 80% humidity for 12 months, the wire maintains ≥97% initial conductivity (vs. bare copper: drops to 85% in 3 months).

- Enhanced Solderability: Tin’s low melting point (232℃) enables “instant wetting” during soldering—no pre-cleaning or flux activation required. Reduces PCB assembly time by 40% vs. bare copper (which needs oxide removal via sanding/chemicals).

- Balanced Thickness Design: 3-5μ thickness avoids two extremes: thinner coatings (<3μ) can’t cover copper flaws, while thicker coatings (>5μ) make the wire brittle (prone to cracking during bending).

Technical Specifications

|

Parameter

|

Detailed Value

|

|

Nominal Diameter (Overall)

|

1.0mm (conductor: ~0.992-0.994mm; tin coating: 3-5μ)

|

|

Diameter Tolerance

|

±0.02mm

|

|

Tin Coating Thickness

|

3μ (minimum) – 5μ (maximum); thickness uniformity: ≥95% (no spot <2.5μ)

|

|

Electrical Conductivity (20℃)

|

≥98% IACS

|

|

Tensile Strength

|

200-250 MPa

|

|

Elongation at Break

|

≥30% (L0=200mm)

|

|

Tin Adhesion

|

No peeling/flaking after 180° bend (radius=5mm) + tape test (3M 610 tape, no tin residue)

|

|

Corrosion Resistance

|

Passes ASTM B117 salt spray test (48h, 5% NaCl, 35℃) – no red rust, tin blistering

|

|

Operating Temperature Range

|

-40℃ (low-temperature flexibility, no cracking) to 105℃ (continuous use, no tin melting)

|

Product Supply & Customization

|

Item

|

Specification

|

|

Supply Form

|

Solid conductor (standard); stranded conductor (custom: 7/0.43mm, 19/0.26mm)

|

|

Spool Configuration

|

500m/1000m per spool (spool material: ABS plastic, diameter: 200mm, core hole: 50mm)

|

|

Surface Finish

|

Bright tin (default); matte tin (custom, for anti-glare applications)

|

|

Additional Treatments

|

Optional insulation (PVC/XLPE/Silicone, thickness: 0.1-0.3mm, color: black/red/blue)

|

|

Packaging

|

Vacuum-sealed aluminum foil bag (moisture-proof) + outer carton (with desiccant, anti-impact)

|

Typical Application Scenarios

- Household Appliances: Internal wiring for washing machines (humidity-resistant), refrigerators (low-temperature flexibility), and microwave ovens (heat resistance up to 105℃).

- Automotive Electronics: Connector terminals for car batteries (anti-corrosion), sensor wiring (stable signal), and in-car infotainment systems (low voltage drop).

- PCB & Consumer Electronics: Through-hole soldering for Arduino/Raspberry Pi boards, USB-C cable conductors, and LED strip wiring (easy assembly).

- Industrial Control: Wiring for PLC panels (industrial humidity resistance) and low-voltage power supplies (minimal energy loss).

- Medical Devices: Internal wiring for portable diagnostic tools (lead-free, compliant with biocompatibility standards) and small medical pumps (flexible bending).

Quality Assurance from Tankii Alloy Material

Every batch of 1.0mm tinned copper wire undergoes three key inspections:

- Tin Thickness Test: X-ray fluorescence (XRF) analyzer (precision: ±0.1μ) – 5 sampling points per spool.

- Conductivity Test: Four-point probe tester (accuracy: ±0.5% IACS) – 3 samples per batch.

- Mechanical Test: Universal testing machine (tensile/elongation) + bend tester (adhesion) – 2 samples per batch.

Free samples (1m length, 2-3 pieces per specification) and detailed Material Test Reports (MTR) are available upon request. Our technical team provides 1-on-1 support for custom requirements (e.g., insulation material selection for high-temperature applications, stranded conductor design for flexible wiring).

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top