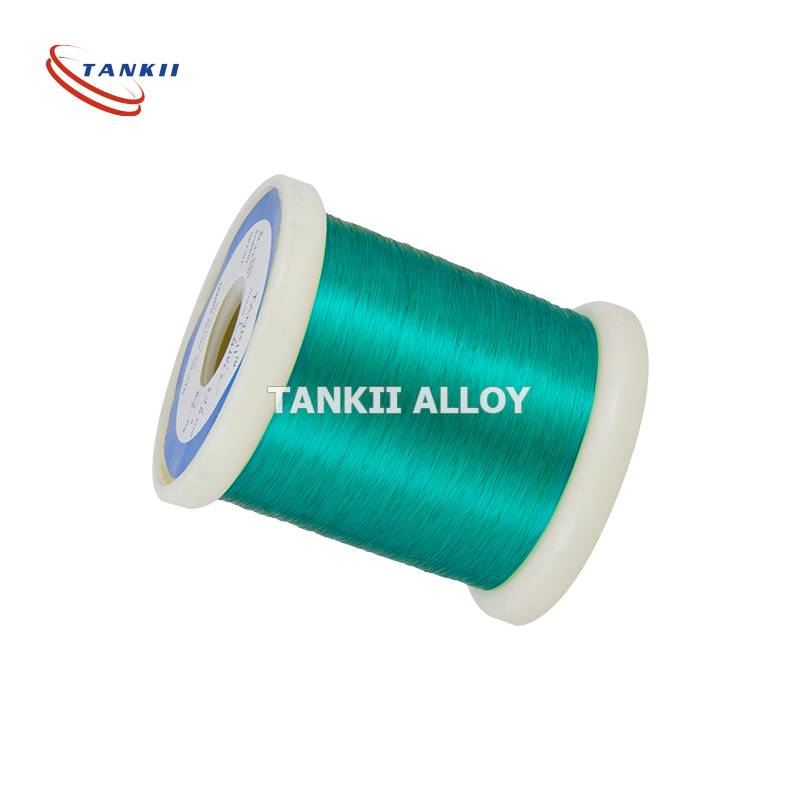

copper wire thermal class C / 200*C ANSI TYPE MW35C or IEC 317-13. Polyester-imide and polyamide-imide double coated enameled Winding wire

copper wire thermal class C / 200*C ANSI TYPE MW35C or IEC 317-13. Polyester-imide and polyamide-imide double coated enameled Winding wire

Product Description

These enameled resistance wires have been broadly used for standard resistors, automobile

parts, winding resistors, etc. using the insulation processing best suited for these applications, taking full advantage of the distinctive features of enamel coating.

Furthermore, we will carry out enamel coating insulation of precious metal wire such as silver and platinum wire upon order. Please make use of this production-on-order.

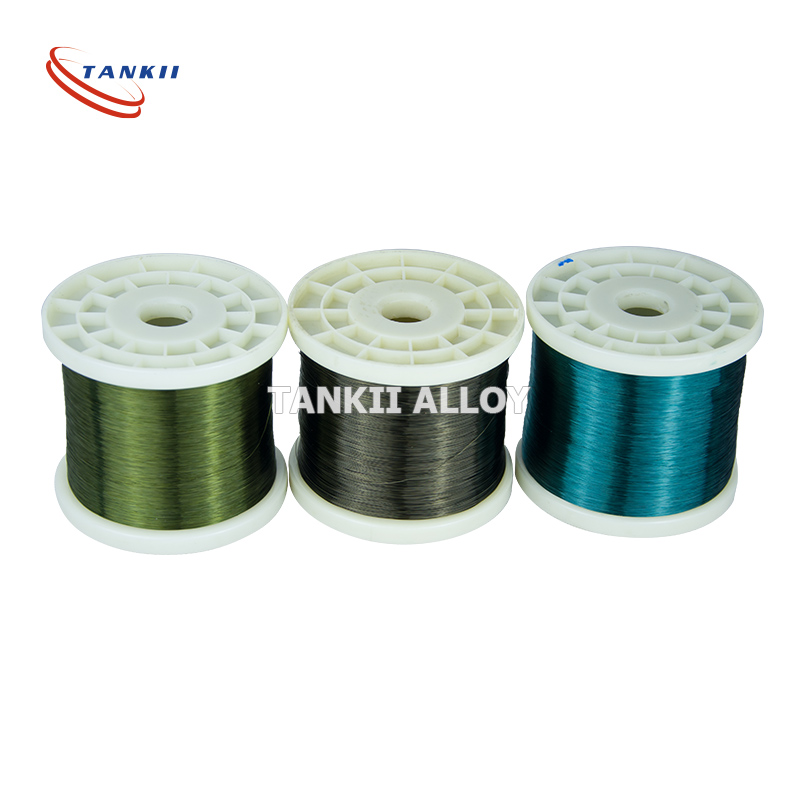

Type Of Nichrome Wire

NiCr80/20,NiCr70/30,NiCr60/15,NiCr90/10,NiCr35/20,NiCr30/20

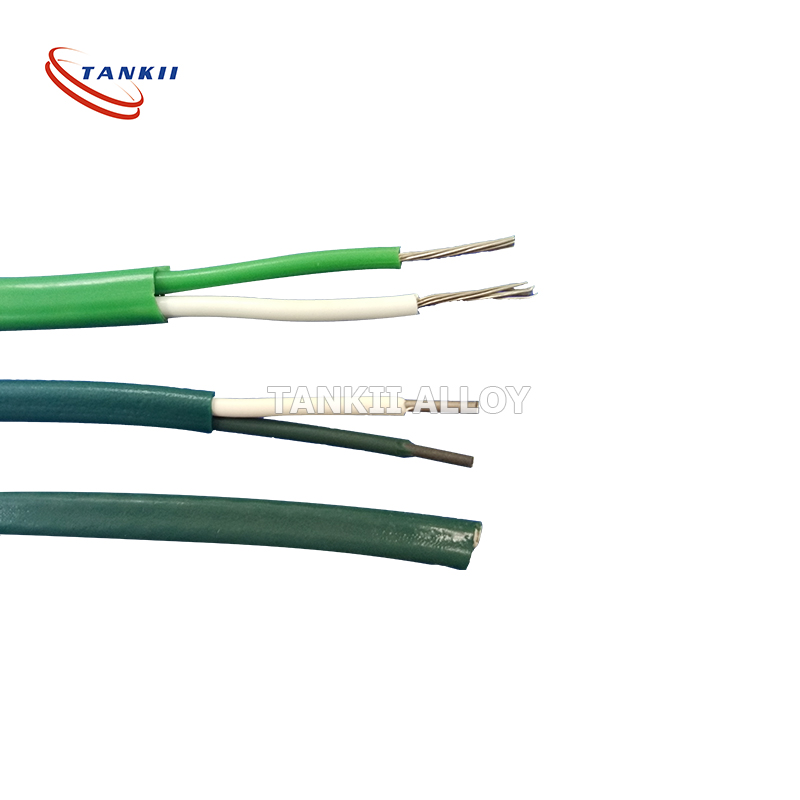

Type of Insulation

| Insulation-enamelled Name | Thermal LevelºC (working time 2000h) |

Code Name | GB Code | ANSI. TYPE |

| Polyurethane enamelled wire | 130 | UEW | QA | MW75C |

| Polyester enamelled wire | 155 | PEW | QZ | MW5C |

| Polyester-imide enamelled wire | 180 | EIW | QZY | MW30C |

| Polyester-imide and polyamide-imide double coated enameled wire | 200 | EIWH (DFWF) |

QZY/XY | MW35C |

| Polyamide-imide enamelled wire | 220 | AIW | QXY | MW81C |

Type Of Bare Alloy Wire

The alloy we can do enamelled are Copper-nickel alloy wire,Constantan wire,Manganin wire. Kama Wire,NiCr Alloy wire,FeCrAl Alloy wire etc alloy wire

| main property type |

Cuni1 | CuNI2 | CuNI6 | CuNi8 | CuNI10 | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNI44 | ||

| main chemical composition |

Ni | 1 | 2 | 6 | 8 | 10 | 14.2 | 19 | 23 | 30 | 34 | 44 | |

| MN | / | / | / | / | / | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | ||

| CU | rest | rest | rest | rest | rest | rest | rest | rest | rest | rest | rest | ||

| max working temperature |

/ | 200 | 220 | 250 | 250 | 300 | 300 | 300 | 350 | 350 | 400 | ||

| density g/cm3 |

8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | ||

| resistivity at 20 °c |

0.03 ± 10% | 0.05± 10% |

0.10± 10% |

0.12± 10% |

0.15± 10% |

0.20± 5% |

0.25± 5% |

0.30± 5% |

0.35± 5% |

0.40± 5% |

0.49± 5% |

||

| temperature coefficient of resistance |

<100 | <120 | <60 | <57 | <50 | <38 | <25 | <16 | <10 | -0 | <-6 | ||

| tensile strength mpa |

>210 | >220 | >250 | >270 | >290 | >310 | >340 | >350 | >400 | >400 | >420 | ||

| elongation | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | ||

| melting point °c |

1085 | 1090 | 1095 | 1097 | 1100 | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | ||

| coefficient of conductivity |

145 | 130 | 92 | 75 | 59 | 48 | 38 | 33 | 27 | 25 | 23 |

nicr8020 alloy heating wire

1.About Nichrome wire

Nichrome alloy includes pure nickel, NiCr alloy, Fe-Cr-Al alloy and copper nickel alloy.

Nickel chrome alloys: Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni30Cr20, Cr25Ni20, pure nickel Ni200 and Ni201

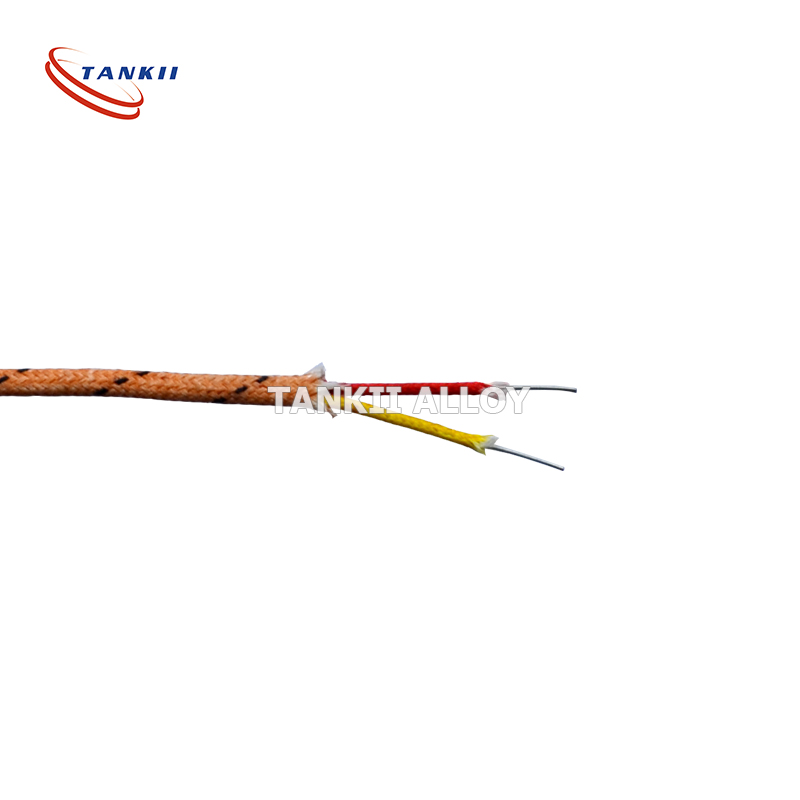

2.Main Advantage and Application

1. Nickel-chromium, nickel-chromium alloy with high and stable resistance, corrosion resistance, surface oxidation resistance is good, a better under high temperature and seismic strength, good ductility, good workability and weldability.

2.Our Products widely apply to chemical industry, metallurgy mechanism, glass industry, ceramic industry, home appliance area and so on.

3.The chemical composition:

| Brand | Chemical composition | Si | Cr | Ni | Al | Fe | |||

| C | P | S | Mn | ||||||

| Not more than | |||||||||

| Cr20Ni80 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 20.0-23.0 | remain | ≤0.50 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 15.0-18.0 | 55.0-61.0 | ≤0.50 | remain |

| Cr20Ni35 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-3.00 | 18.0-21.0 | 34.0-37.0 | - | remain |

| Cr20Ni30 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-2.00 | 18.0-21.0 | 30.0-34.0 | - | remain |

When the product is at “M” status, should be followed the standard GB/T1234-1995

Resistivity:

| Brand | Cr20Ni80 | Cr20Ni60 | Cr20Ni35 | Cr20Ni30 | ||

| Diameter mm | <0.50 | 0.50-3.0 | <0.50 | ≥0.50 | <0.50 | ≥0.50 |

| resistivity(20°C)uΩ·m | 1.09±0.05 | 1.13±0.05 | 1.12±0.05 | 1.15±0.05 | 1.04±0.05 | 1.06±0.05 |