electric heating element - China Manufacturers, Factory, Suppliers

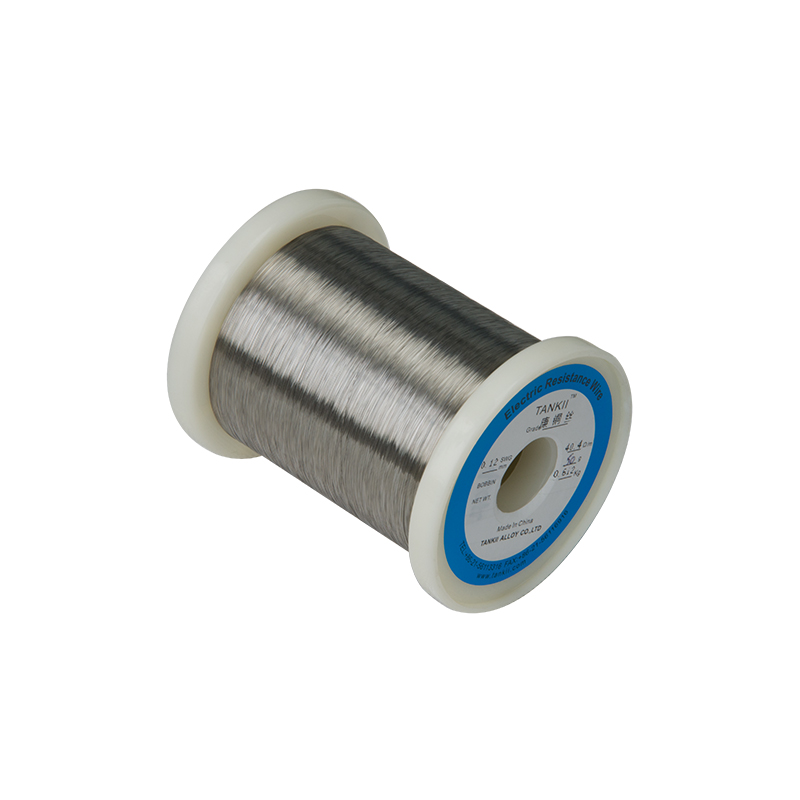

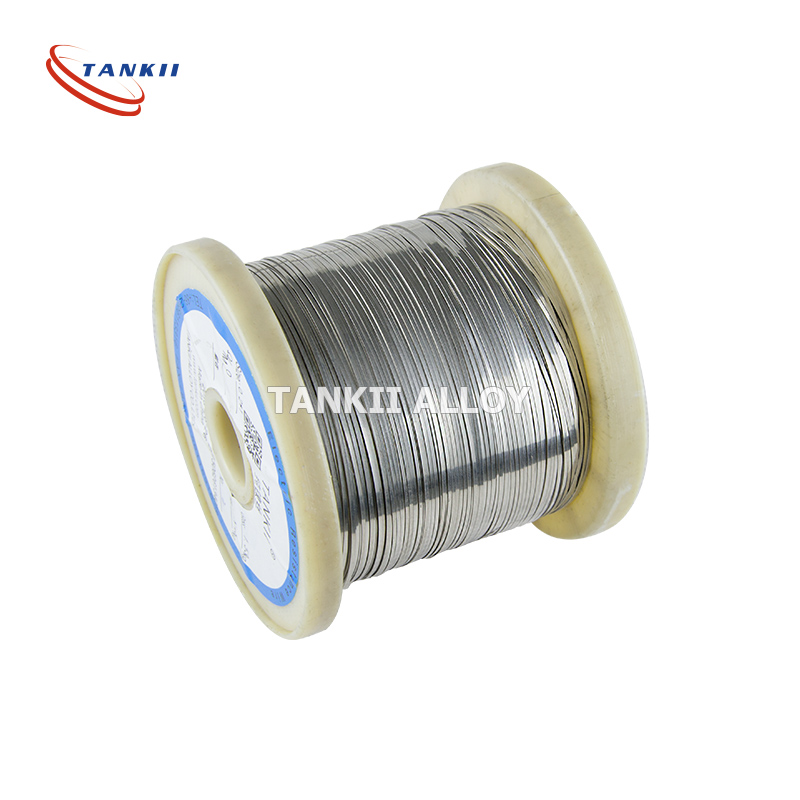

Our commission is always to provide our customers and clientele with best quality and aggressive portable digital products for electric heating element, Alkrothal 720 , Nickel Wire , Lohm ,Monel . We welcome clients, enterprise associations and friends from all components from the earth to make contact with us and find cooperation for mutual positive aspects. The product will supply to all over the world, such as Europe, America, Australia,British, Pakistan,Benin, Oman.We've been always creating new technology to streamline the production, and give products with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We are going to present our best service to satisfy all your needs! Remember to contact us right away!

Related Products