Welcome to our websites!

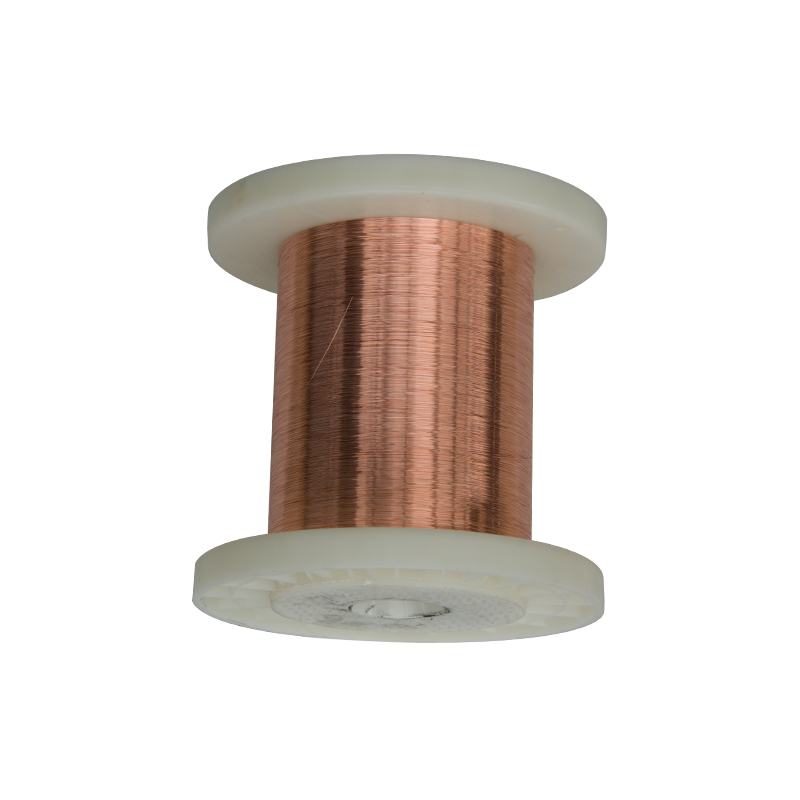

CuNi10 resistance wire corrosion-resistant for electric heating element

CuNi10 Copper-nickel is a copper-nickel alloy formulated for primary forming into wrought products. Cited properties are appropriate for the annealed condition. CuNi10 is the EN chemical designation for this material. C70700 is the UNS number.

It has a moderately low tensile strength among the wrought copper-nickels in the database.

This heating resistor material is more corrosion reistant than CuNi2 und CuNi6.

We usually manufacture within a +/-5% tolerance of the electrical resistivity.

Product Details

| JIS | JIS Code | Electrical Resistivity [μΩm] |

Average TCR [×10-6/℃] |

|---|---|---|---|

| GCN15 | C 2532 | 0.15±0.015 | *490 |

(*)Reference value

| Thermal Expansion Coefficient ×10-6/ |

Density g/cm3 (20℃ |

Melting Point ℃ |

Max Operating Temperature ℃ |

|---|---|---|---|

| 17.5 | 8.90 | 1100 | 250 |

| Chemical Composition |

Mn | Ni | Cu+Ni+Mn |

|---|---|---|---|

| (%) | ≦1.5 | 20~25 | ≧99 |

Write your message here and send it to us