Welcome to our websites!

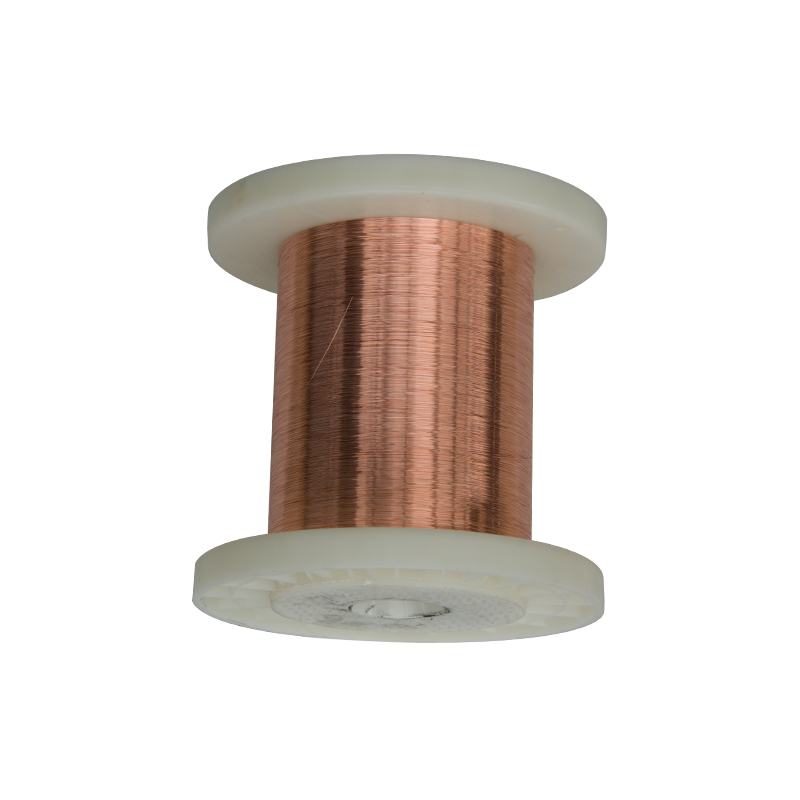

CuNi10/C70700/W.Nr. 2.0811/Cu7061/CN15 /Cuprothal 15 resistance wire used at low temperatures.

Due to high tensile strength and increased resistivity values, CuNi10 is the first choice for applications as resistance wires. With the different nickel amount in this product range, the characteristics of the wire can be chosen according to your requirements. Copper-nickel alloy wires are available as bare wire, or enameled wire with any insulation and self-bonding enamel.

This alloy presents the particularity to be very malleable, to have good resistance to corrosion until temperatures of 400°C, and good solderability. Ideal application areas are all types of resistances used at low temperatures.

Product Details

| JIS | JIS Code | Electrical Resistivity [μΩm] |

Average TCR [×10-6/℃] |

|---|---|---|---|

| GCN15 | C 2532 | 0.15±0.015 | *490 |

(*)Reference value

| Thermal Expansion Coefficient ×10-6/ |

Density g/cm3 (20℃ |

Melting Point ℃ |

Max Operating Temperature ℃ |

|---|---|---|---|

| 17.5 | 8.90 | 1100 | 250 |

| Chemical Composition |

Mn | Ni | Cu+Ni+Mn |

|---|---|---|---|

| (%) | ≦1.5 | 20~25 | ≧99 |

Write your message here and send it to us