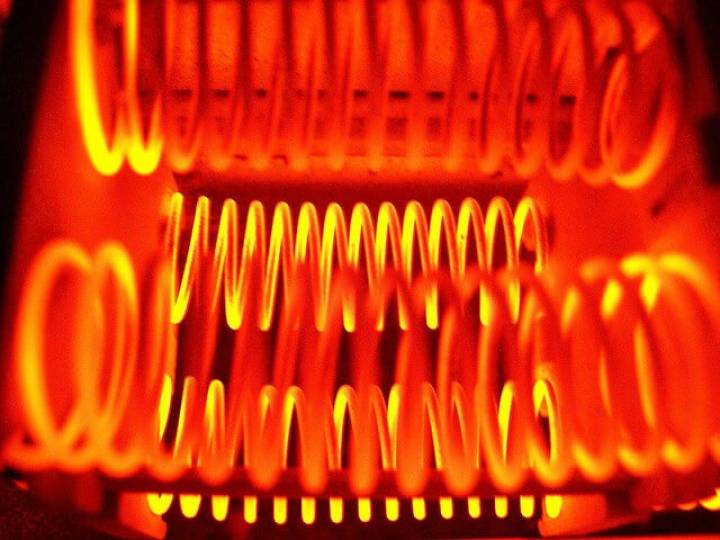

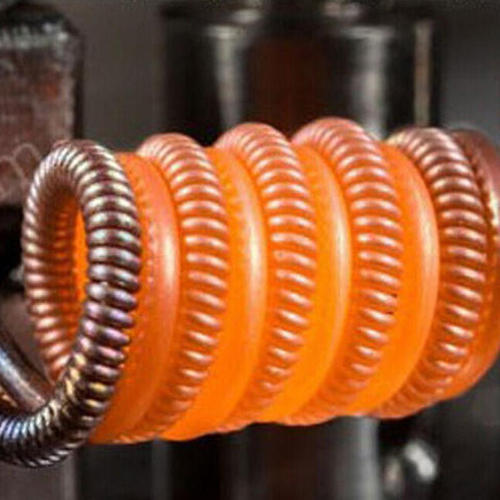

FeCrAl 0Cr25Al5 heating electric stove wire heating coil

Main Property of heating resistance wire

| Alloy Type | Diameter (mm) |

Resistivity (μΩm)(20°C) |

Tensile Strength (N/mm²) |

Elongation(%) | Bending Times |

Max.Continuous Service Temperature(°C) |

Working Life (hours) |

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

| NAME | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| MAIN CHEMICAL | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| COMPOSITION | Re | opportune | opportune | opportune | opportune | opportune | opportune | opportune |

| Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

| Nb0.5 | Mo1.8-2.2 | |||||||

| MAX TEMPERATURE(oC) | 650 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| RESISTANCE20oC (μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| DENSITY(g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| HEAT EXCHANGE | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| RATE(KJ/m·h·oC) | ||||||||

| expansion rate(α×10-6/oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| melting point( oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| tensile strength(N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| elongation(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| magnetic property | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

| Diameter(mm) | Tolerance(mm) | Diameter(mm) | Tolerance(mm) |

| 0.03-0.05 | ±0.005 | >0.50-1.00 | ±0.02 |

| >0.05-0.10 | ±0.006 | >1.00-3.00 | ±0.03 |

| >0.10-0.20 | ±0.008 | >3.00-6.00 | ±0.04 |

| >0.20-0.30 | ±0.010 | >6.00-8.00 | ±0.05 |

| >0.30-0.50 | ±0.015 | >8.00-12.0 | ±0.4 |

| Thickness(mm) | Tolerance(mm) | Width(mm) | Tolerance(mm) |

| 0.05-0.10 | ±0.010 | 5.00-10.0 | ±0.2 |

| >0.10-0.20 | ±0.015 | >10.0-20.0 | ±0.2 |

| >0.20-0.50 | ±0.020 | >20.0-30.0 | ±0.2 |

| >0.50-1.00 | ±0.030 | >30.0-50.0 | ±0.3 |

| >1.00-1.80 | ±0.040 | >50.0-90.0 | ±0.3 |

| >1.80-2.50 | ±0.050 | >90.0-120.0 | ±0.5 |

| >2.50-3.50 | ±0.060 | >120.0-250.0 | ±0.6 |

I We are manufacturer of heating resistance wire includes

FeCrAL wire, NiCr wire, CuNi wire:

II Main Advantage and Application

A. Physical parameter:

1) Wire diameter: 0.025 ~ 15mm

2) Pure nickel has the ability to withstand relatively high temperatures without deterioration. Maximum operating

temperature is approximate 600°C

3) Nickel wire is available in single strand or multi-strand construction. It is supplied from stock either bare, or insulated

B. Characteristics:

1) Excellent straightness

2) Uniform and beautiful surface condition without spots

3) Excellent coil-forming ability

C. Main applications and general purpose:

1) This wire can also be widely used in generally specified for transistor caps, anodes for electronic tubes,

leads of electronic components / lead-in-wires for lamps and for wire-mesh. Also used in strip form for various

applications including Ni-Cd batteries

2) Also used for cables, Lead-in-Wire for lamps, electronic tube supports, wire cloth electrical connecting leads

where temperatures are in excess of those for which copper is suitable, wire weaving

3) Typical applications include: terminations for heating elements as in ovens, plastics extruders, furnaces.

Filament supports and lead wires in the lighting industry