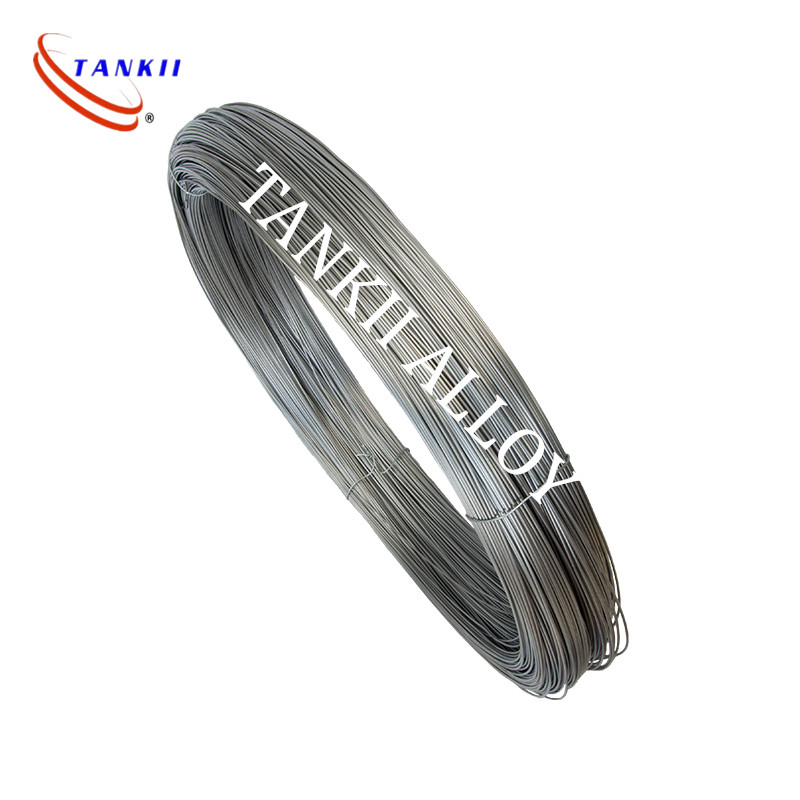

FeNi Nickel Iron Alloy Precision 0.5mm Invar 36 Wire For Sealing Precision Instrument

FeNi Nickel Iron alloy precision 0.5mm Invar 36 Wire for Sealing Precision Instrument

INVAR 36 is a nickel-iron, low expansion alloy containing 36% nickel. It maintains nearly constant Dimensions Over the range of normal atmospheric temperatures, and has a low coefficient of expansion from cryogenic temperatures to about 500° F. The alloy also retains good strength and toughness at cryogenic temperatures.

INVAR 36 can be hot and cold formed and machined using processes similar to

austenitic stainless steels. INVAR 36 is weldable using Filler Metal CF36 which is

available in bare wire for both the GTAW and GMAW process.

Chemical composition

| composition | % | Fe | Ni | Mn | C | P | S | SI |

| content | min | Bal | 35.0 | 0.2 | ||||

| max | 37.0 | 0.6 | 0.05 | 0.02 | 0.02 | 0.3 |

physical properties

| Density (g/cm3) 8.1 |

| Electrical resistivity at 20ºC(mm2/m) 0.78 |

| Temperature factor of resistivity(20ºC~200ºC)X10-6/ºC 3.7~3.9 |

| Thermal conductivity, λ/ W/(m*ºC) 11 |

| Curie point Tc/ ºC 230 |

| Elastic Modulus, E/ Gpa 144 |

| Melting point ºC 1430 |

Coefficient of expansion

| θ/ºC | α1/10-6ºC-1 | θ/ºC | α1/10-6ºC-1 |

| 20~-60 | 1.8 | 20~250 | 3.6 |

| 20~-40 | 1.8 | 20~300 | 5.2 |

| 20~-20 | 1.6 | 20~350 | 6.5 |

| 20~-0 | 1.6 | 20~400 | 7.8 |

| 20~50 | 1.1 | 20~450 | 8.9 |

| 20~100 | 1.4 | 20~500 | 9.7 |

| 20~150 | 1.9 | 20~550 | 10.4 |

| 20~200 | 2.5 | 20~600 | 11.0 |

Typical Mechanical properties

| Tensile Strength | Elongation |

| Mpa | % |

| 641 | 14 |

| 689 | 9 |

| 731 | 8 |

Temperature factor of Resistivity

| Temperature range, ºC | 20~50 | 20~100 | 20~200 | 20~300 | 20~400 |

| aR/ 103 *ºC | 1.8 | 1.7 | 1.4 | 1.2 | 1.0 |

| The heat treatment process | |

| Annealing for stress relief | Heated to 530~550ºC and hold 1~2 h. Cold down |

| annealing | In order to eliminate hardening, which be bring out in cold-rolled, cold drawing process. Annealing needs heated to 830~880ºC in vacuum,hold 30 min. |

| The stabilization process | In protective media and heated to 830 ºC, hold 20min. ~ 1h, quench Due to the stress generated by quenching, heated to 315ºC,hold 1~4h. |

| Precautions | Can not be hardened by heat treatment Surface treatment can be sandblasting, polishing or pickling. Alloy can be used 25% hydrochloric acid pickling solution at 70 ºC to clear oxidized surface |