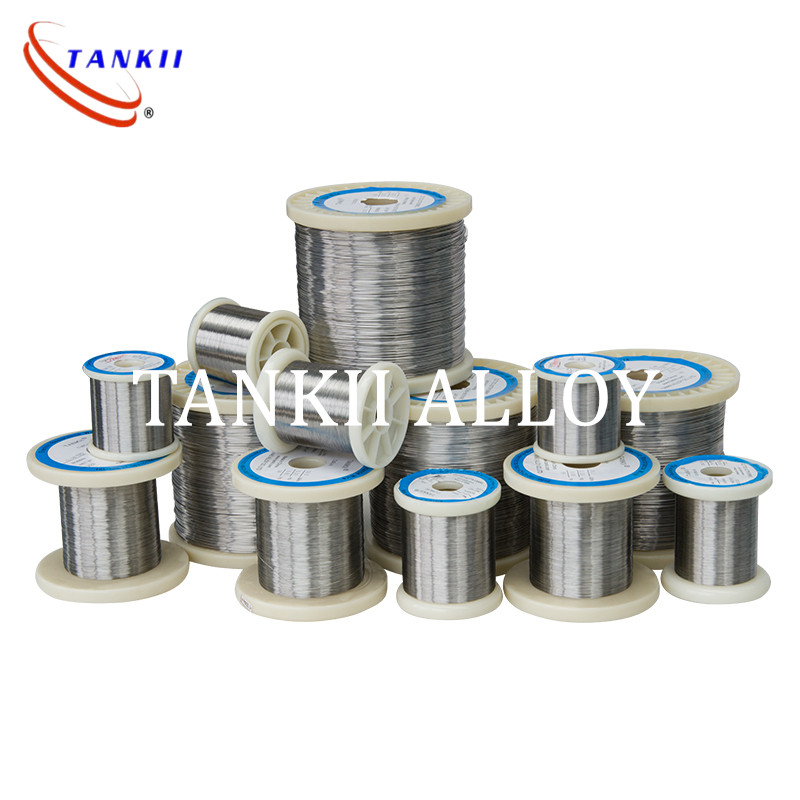

Fecral 135 Alloy Electric Resistance Heating Wire 0cr25al5 0cr23al5 0cr21al6 For Heater Coils

FeCrAl 135 Alloy Electric Resistance Heating Wire Ocr25al5 Ocr23al5 Ocr21al6 for Heater Coils

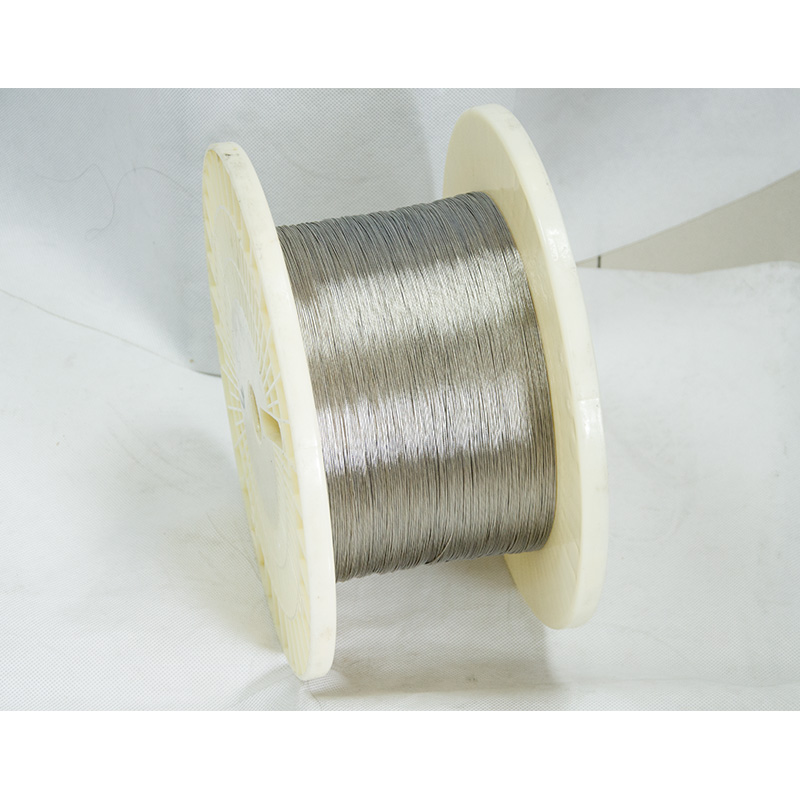

FeCrAl135 is a ferritic iron-chromium-aluminium alloy (FeCrAl alloy) for use at temperatures up to 1300°C (2370°F). The alloy is characterized by high resistivity and good oxidation resistance.

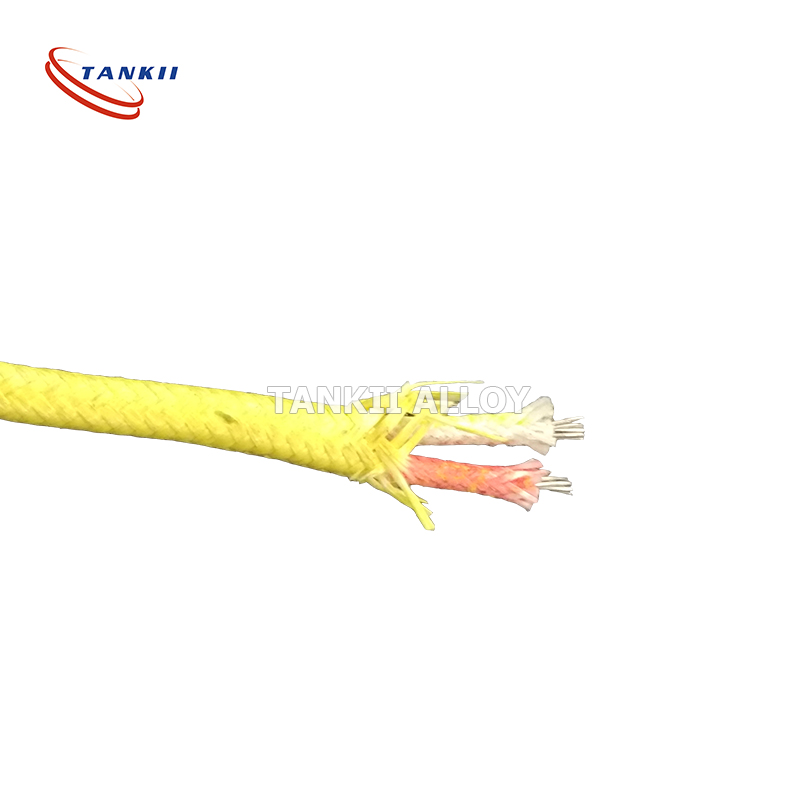

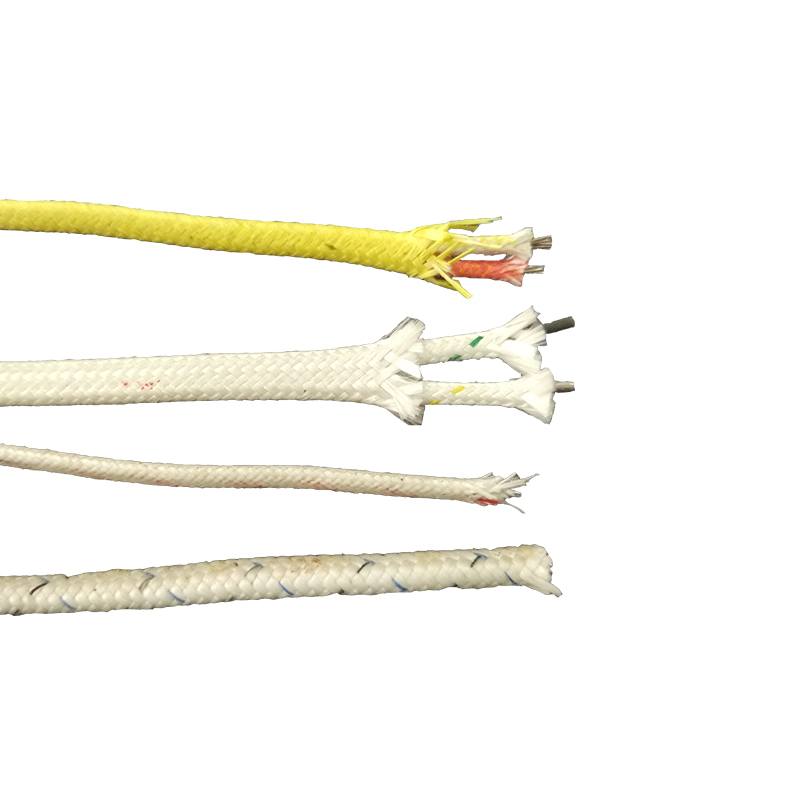

FeCrAl135 is used in home appliances and industrial furnaces. Typical applications in home appliances include metal sheathed tubular elements for dishwashers, elements embedded in ceramics for panel heaters, cartridge elements in metal dies, heating cables and rope heaters in defrosting and deicing elements, mica elements used in irons, quartz tube heaters for space heating, industrial infrared dryers, in coils on molded ceramic fibre for boiling plates with ceramic hobs, in bead insulated coils for panel heaters, in suspended coil elements for air heaters in laundry dryers.

In industrial applications FeCrAl135 is used in, for example, terminals to furnace elements, porcupine elements for air heating, and in furnace heating elements.

CHEMICAL COMPOSITION

| C% | Si% | Mn% | Cr% | Al% | Fe% | |

| Nominal composition | 5.3 | Bal. | ||||

| Min | - | - | - | 23.0 | - | |

| Max | 0.05 | 0.5 | 0.45 | 25.0 | - |

MECHANICAL PROPERTIES

| Thickness | Yield strength | Tensile strength | Elongation | Hardness |

| Rρ0.2 | Rm | A | ||

| mm | Mpa | MPa | % | Hv |

| 2.0 | 450 | 650 | 18 | 200 |

PHYSICAL PROPERTIES

| Density g/cm3 | 7.15 |

| Electrical resistivity at 20°C Ω mm /m | 1.35 |

| Maximum use temperature °C | 1300 |

| Melting point °C | 1500 |

| Magnetic Property | Magnetic |

TEMPERATURE FACTOR OF RESISTIVITY

| Temperature °C | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 | 1300 |

| Ct | 1.00 | 1.01 | 1.01 | 1.02 | 1.03 | 1.03 | 1.04 | 1.04 | 1.04 | 1.05 | 1.05 | 1.05 |