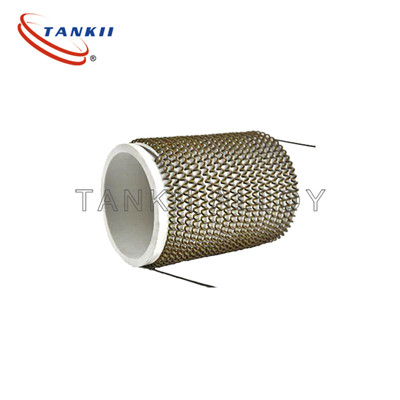

Spring Coil

product description

Our company produces high-quality iron-chromium-aluminum and nickel-chromium electric heating alloy wires, which adopt computer-controlled furnace wire power and are wound into shape by a high-speed automatic winding machine. The characteristics of this product: high temperature resistance, fast heating, long service life, stable resistance, small power deviation, uniform pitch after stretching, bright and clean surface; widely used in small electric furnaces, muffle furnaces, heating and air conditioning equipment, various ovens, Electric heating tubes and household appliances, etc. Various non-standard industrial and civil furnace bars can be designed and produced according to user needs.

|

Power W |

Voltage V |

Diameter mm |

OD mm |

Length (Reference) mm |

Weight g |

|

300 |

220 |

0.25 |

3.7 |

122 |

1.9 |

|

500 |

220 |

0.35 |

3.9 |

196 |

4.3 |

|

600 |

220 |

0.40 |

4.2 |

228 |

6.1 |

|

800 |

220 |

0.50 |

4.7 |

302 |

11.1 |

|

1000 |

220 |

0.60 |

4.9 |

407 |

18.5 |

|

1200 |

220 |

0.70 |

5.6 |

474 |

28.5 |

|

1500 |

220 |

0.80 |

5.8 |

554 |

39.0 |

|

2000 |

220 |

0.95 |

6.1 |

676 |

57.9 |

|

2500 |

220 |

1.10 |

6.9 |

745 |

83.3 |

|

3000 |

220 |

1.20 |

7.1 |

792 |

98.3 |

The temperature and chemical composition of the heating wire

|

Grade |

Max. Conti uous Operating Temper. |

Cr% |

Ni% |

Al% |

Fe% |

Re% |

Nb% |

Mo% |

|

Cr20Ni80 |

1200℃ |

20~23 |

Bal. |

|

|

|

|

|

|

Cr30Ni70 |

1250℃ |

28~31 |

Bal. |

|

|

|

|

|

|

Cr15Ni60 |

1150℃ |

15~18 |

55~61 |

|

Bal. |

|

|

|

|

Cr20Ni35 |

1100℃ |

18~21 |

34~37 |

|

Bal. |

|

|

|

|

TANKII APM |

1425℃ |

20.5~23.5 |

|

5.8 |

Bal. |

/ |

|

|

|

0Cr27Al7Mo2 |

1400℃ |

26.5~27.8 |

|

6~7 |

Bal. |

|

|

2 |

|

0Cr21Al6Nb |

1350℃ |

21~23 |

|

5~7 |

Bal. |

|

0.5 |

|

|

0Cr25Al5 |

1250℃ |

23~26 |

|

4.5~6.5 |

Bal. |

|

|

|

|

0Cr23Al5Y |

1300℃ |

22.5~24.5 |

|

4.2~5.0 |

Bal. |

|

|

|

|

0Cr19Al3 |

1100℃ |

18~21 |

|

3~4.2 |

Bal. |

|

|

|

Main technical properties of FeCrAl alloy wire:

①The use temperature is high, the use temperature of the iron-chromium aluminum alloy wire in the atmosphere can reach 1300℃;

②Long service life;

③The allowable surface load is large;

⑤The specific gravity is smaller than the nickel-chromium alloy; ④The oxidation resistance is good, and the AI2O3 film formed after oxidation has good chemical resistance and high resistivity;

⑥High resistivity;

⑦Good sulfur resistance;

⑧The price is significantly lower than that of nickel-chromium alloy;

⑨The disadvantage is that as the temperature increases, it exhibits plasticity, and the strength at high temperatures is low.

The characteristics of nickel-chromium electric stove wire are:

① High strength at high temperature;

②Cool down after long-term use, the material will not become brittle;

③The emissivity of fully oxidized Ni-ming alloy is higher than that of Fe-Cr-Al alloy;

④No magnetism;

⑤Except for sulfur atmosphere, it has better corrosion resistance