Coffee Machine Heating Element, Bayonet Electric Heater, Electric Heating Resistance

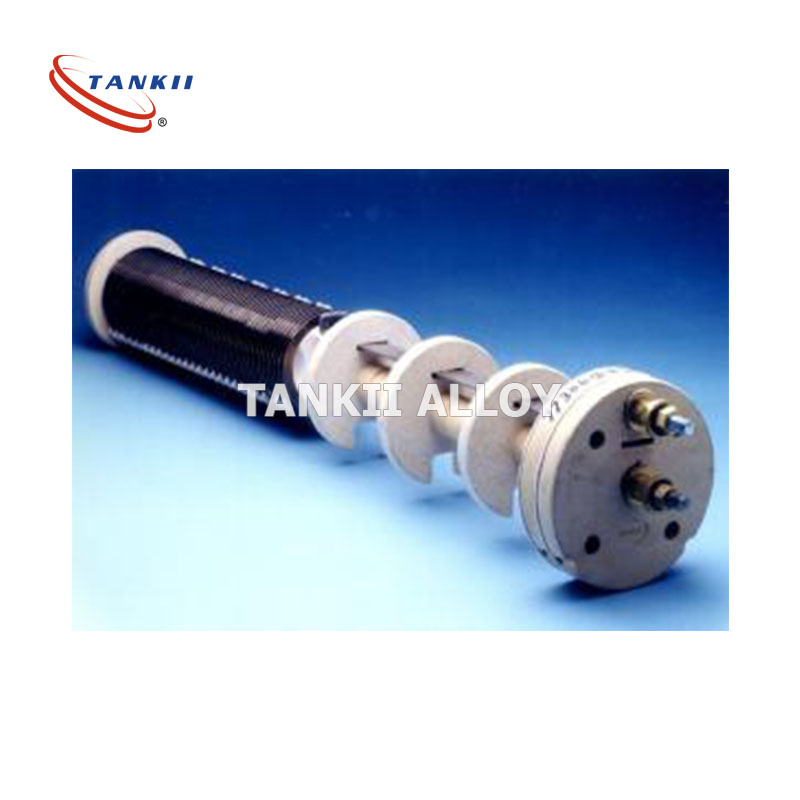

Bayonet heating elements are a reliable and efficient solution for electric heating applications.

These elements are custom designed for the voltage and input (KW) required to satisfy the application. There are a wide variety of configurations available in either large or small profiles. Mounting can be vertical or horizontal, with heat distribution selectively located according to the required process. Bayonet elements are designed with ribbon alloy and watt densities for furnace temperatures up to 1800°F (980°C).

Advantages

- Element replacement is fast and easy. Element changes can be made while the furnace is hot, following all plant safety procedures. All electrical and replacement connections can be made outside the furnace. No field welds are necessary; simple nut and bolt connections allow for quick replacements. In some cases, replacement can be completed in as little as 30 minutes depending on the size of the element complexity and accessibility.

- Each element is custom designed for peak energy efficiency. Furnace temperature, voltage, desired wattage and material selection are all used in the design process.

- Inspection of the elements can be performed outside the furnace.

- When necessary, as with a reducing atmosphere, bayonets can be operated in sealed alloy tubes.

- Repairing a SECO/WARWICK bayonet element may be an economical alternative. Consult us for current pricing and repair options.

Typical Configurations

Below are sample configurations. Lengths will vary with specifications. Standard diameters are 2-1/2” and 5”. Placement of supports varies with the orientation and length of the element.

Company Profile

Shangahi Tankii Alloy Material Co.,Ltd focus on the production of Nichrome Alloy,Thermocouple wire,FeCrAl alloy,Precision alloy,Copper Nickel Alloy,Thermal Spray Alloy etc in the form of wire ,sheet ,tape,strip,rod and plate.

We've already got ISO9001 quality system certificate and approval of ISO 14001 environmental protection system.We own a complete set of advanced production flow of refining ,cold reduction,drawing and heat treating etc.We also proudly have independent R&D capacity.

Shanghai Tankii Alloy material Co.,Ltd has accumulated lots of experiences over 35 years in this field. During these years,more than 60 management elites and high science and technology talents were employed.They participated in every walk of the company life,which make our company keep blooming and invincible in the competitive market.

Based on the principle of"first quality,sincere service",our managing ideology is pursuing technology innovation and creating the top brand in the alloy field.We persist in quality -the foundation of the survival.It is our forever ideology to serve you with full heart and soul.We committed to provide customers all over the world with high -quality ,competitive products and perfect service.

Our products,such as nichrome alloy,precision alloy,thermocouple wire ,fecral alloy ,copper nickel alloy, thermal spray alloy have been exported to over 60 countries in the world.

We are willing to establish strong and long-time partnership with our customers.

Most complete range of products dedicated to resistance,thermocouple and furnace manufacturers.

Quality with end to end production control.

Technical support and customer service.